Boundary condition-based single-drive two-way piezoelectric motor

A piezoelectric motor and boundary condition technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., which can solve the problems of limited application and bulky piezoelectric motor systems. , to achieve the effect of simple structure, reduced volume and power consumption, and low driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

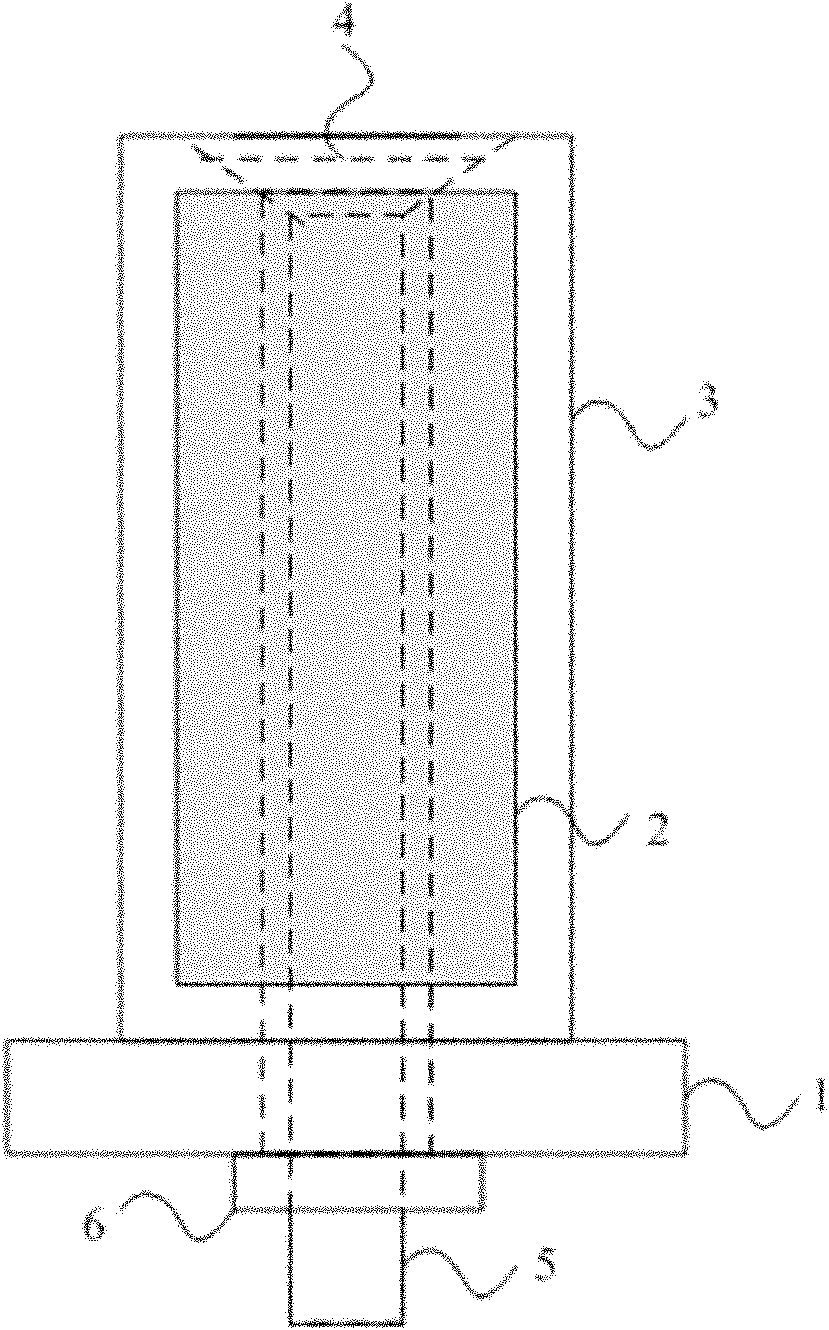

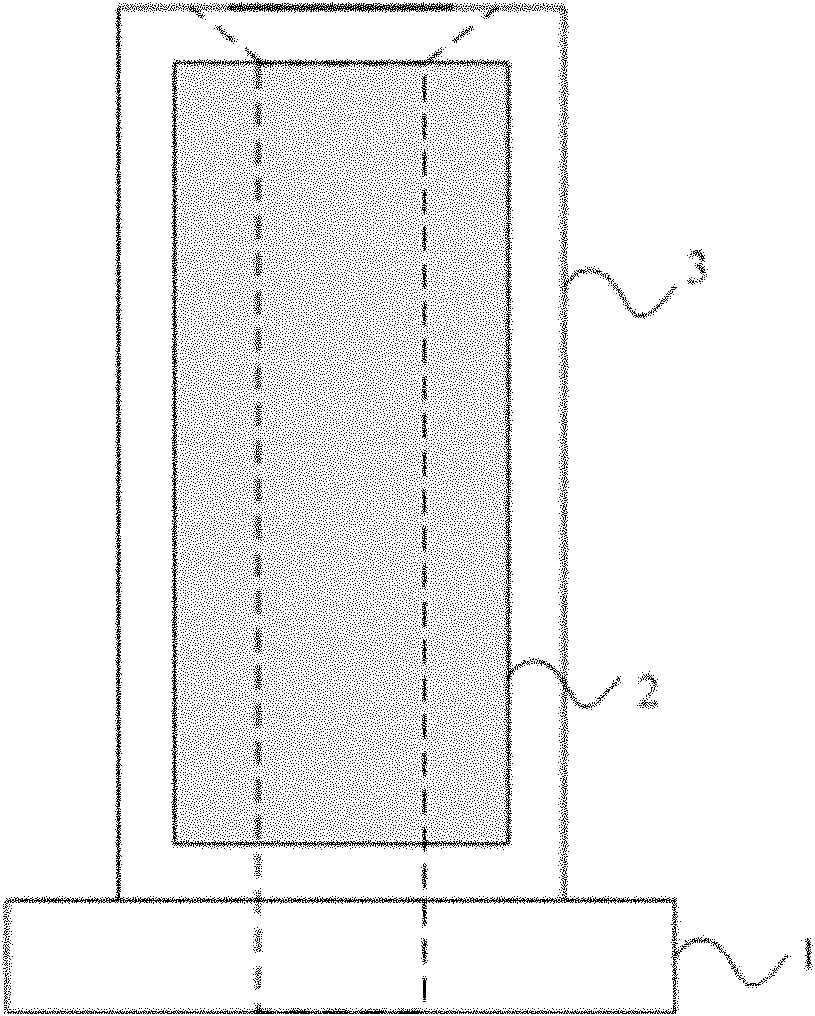

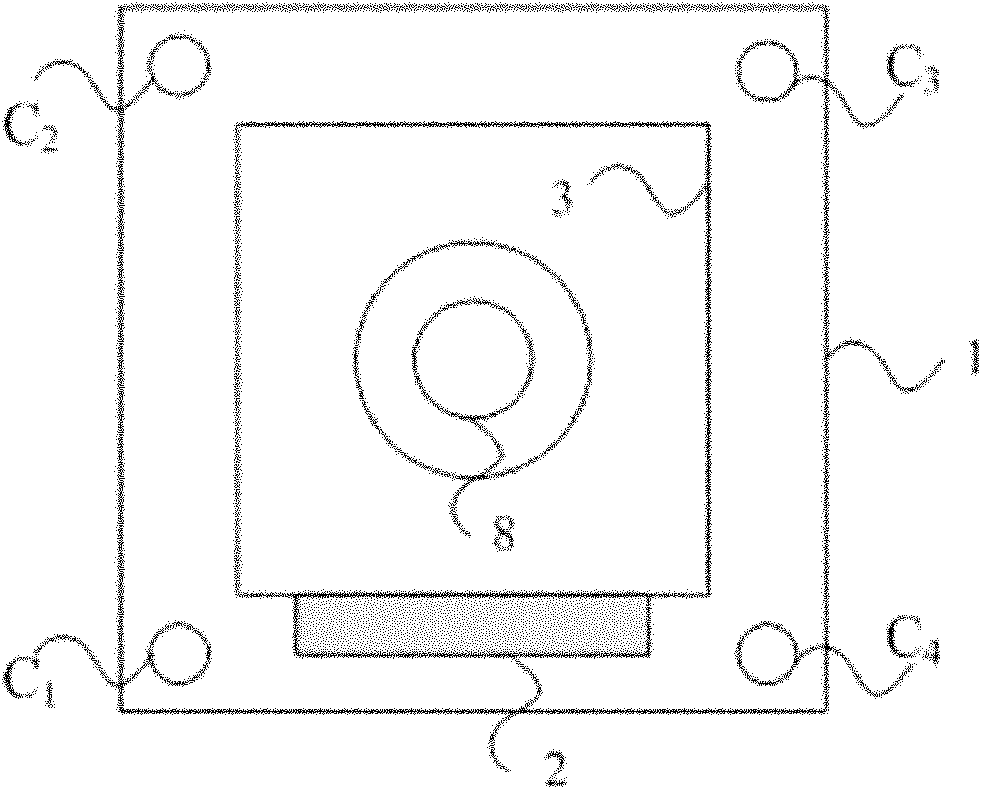

[0025] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the piezoelectric motor of the present invention includes a base 1, a stator fixedly connected to the base 1, and a rotor that can rotate relative to the stator and the base 1; the stator includes a driving body 3 with a central hole 8 and is connected to the The piezoelectric sheet 2 on one side of the driving body 3; the central hole 8 in the driving body 3 runs through the base 1; the rotor includes a rotating body 5 passing through the central hole 8 of the driving body 3 and a cap fixedly connected to one end of the rotating body 5 4; The cap body 4 is in contact with the driving body 3, and there is a gap between the rotating body 5 and the center hole 8 of the driving body 3; the edge of the base 1 is provided with four screw holes symmetrically distributed, respectively marked clockwise For screw hole C 1 , screw hole C 2 , screw hole C 3 and screw hole C 4 , as the boundary condition; screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com