Vacuum pump

A vacuum pump and rotor technology, applied to pumps, pump components, axial flow pumps, etc., can solve the problems of increasing the risk of collision, changing other properties of pump rotors, accelerating material fatigue, etc., to achieve the effect of ensuring originality and licensing qualification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

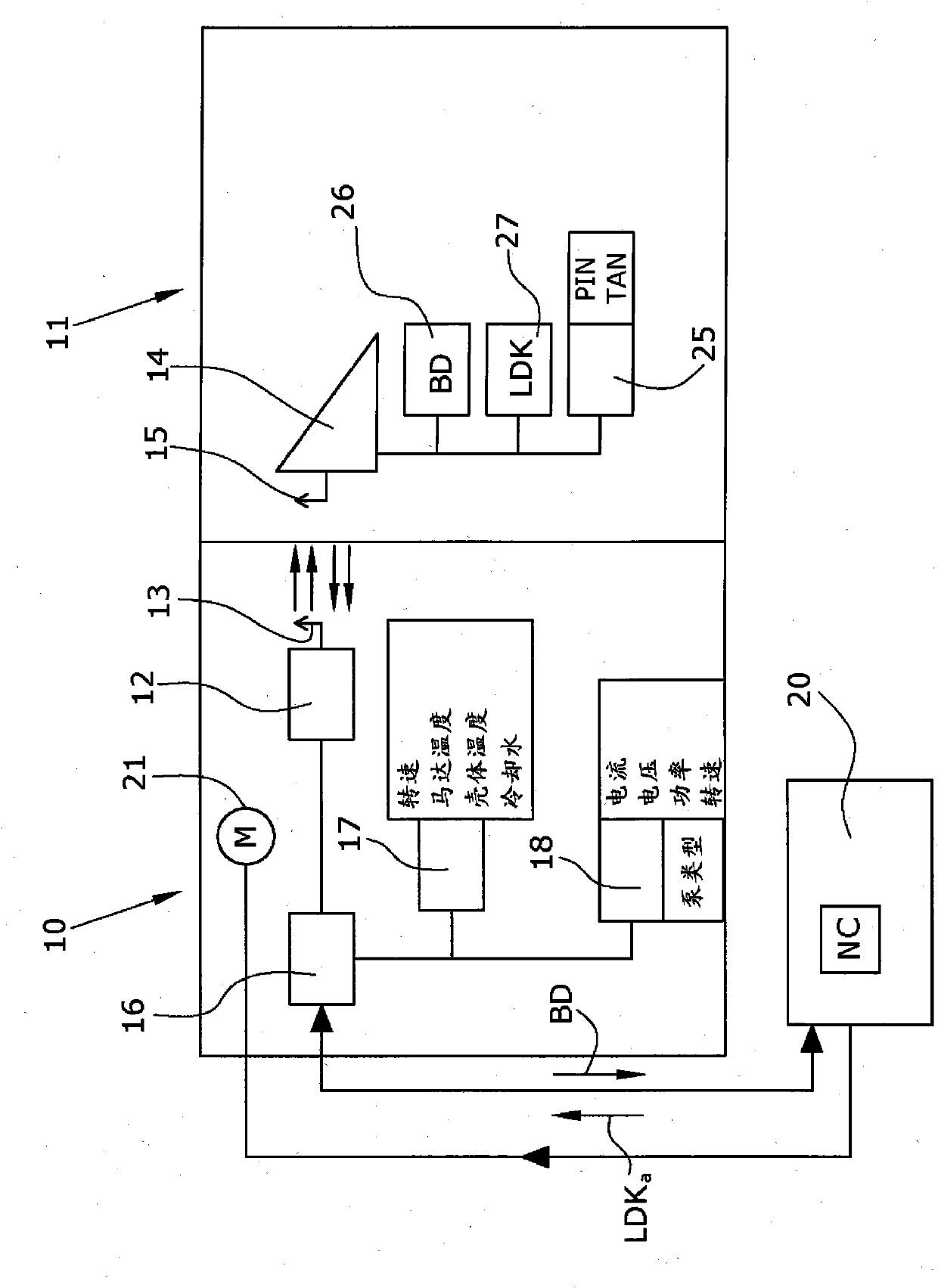

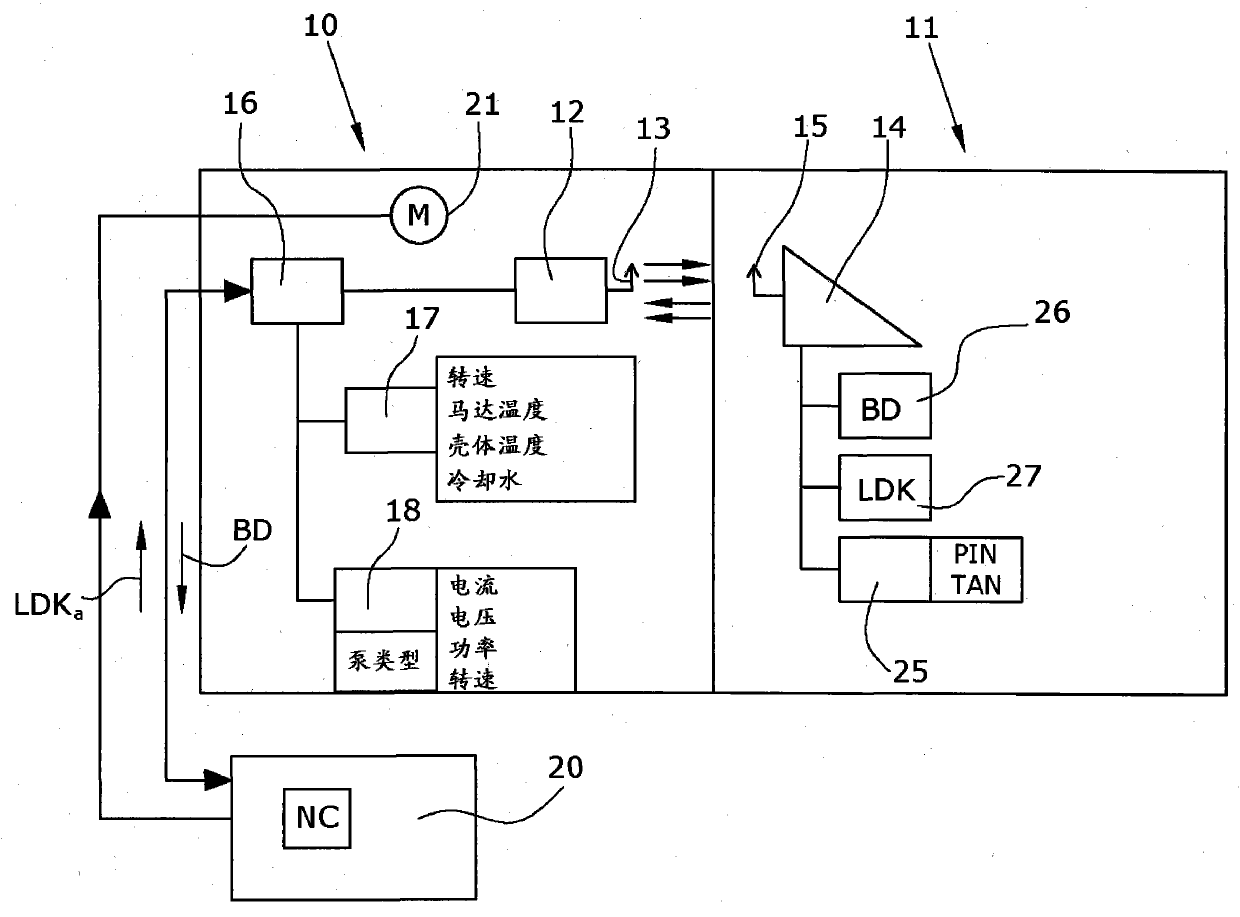

[0016] The construction of the vacuum pump is the same as in WO 2007 / 025854 A1, the content of which is incorporated into this description by reference. The vacuum pump is a turbomolecular pump with a rapidly rotating pump rotor. Interengaging vane rows are located on the pump rotor and the pump stator. Only the pump stator 10 and the pump rotor 11 are shown schematically in the figures, since in this context it is primarily the communication system that is relevant to the invention.

[0017] The pump stator contains a reader 12 of a radio frequency identification (RFID) system. The reader is connected to the stator antenna 13 . The pump rotor contains an RFID transponder 14 or tag with a rotor antenna 15 . Data transmission between reader 12 and transponder 14 takes place wirelessly and bidirectionally via antennas 13 and 15 .

[0018] The reader 12 is provided with a (not shown) power supply. The transponder 14 can be powered wirelessly by the reader via the antennas 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com