Full-automatic paper holding machine

A paper support machine, fully automatic technology, applied in the direction of object separation, object supply, pile separation, etc., can solve the problems of paper support being difficult to separate, high error rate, low efficiency, etc., to achieve the effect of full automation, coherent and fast action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

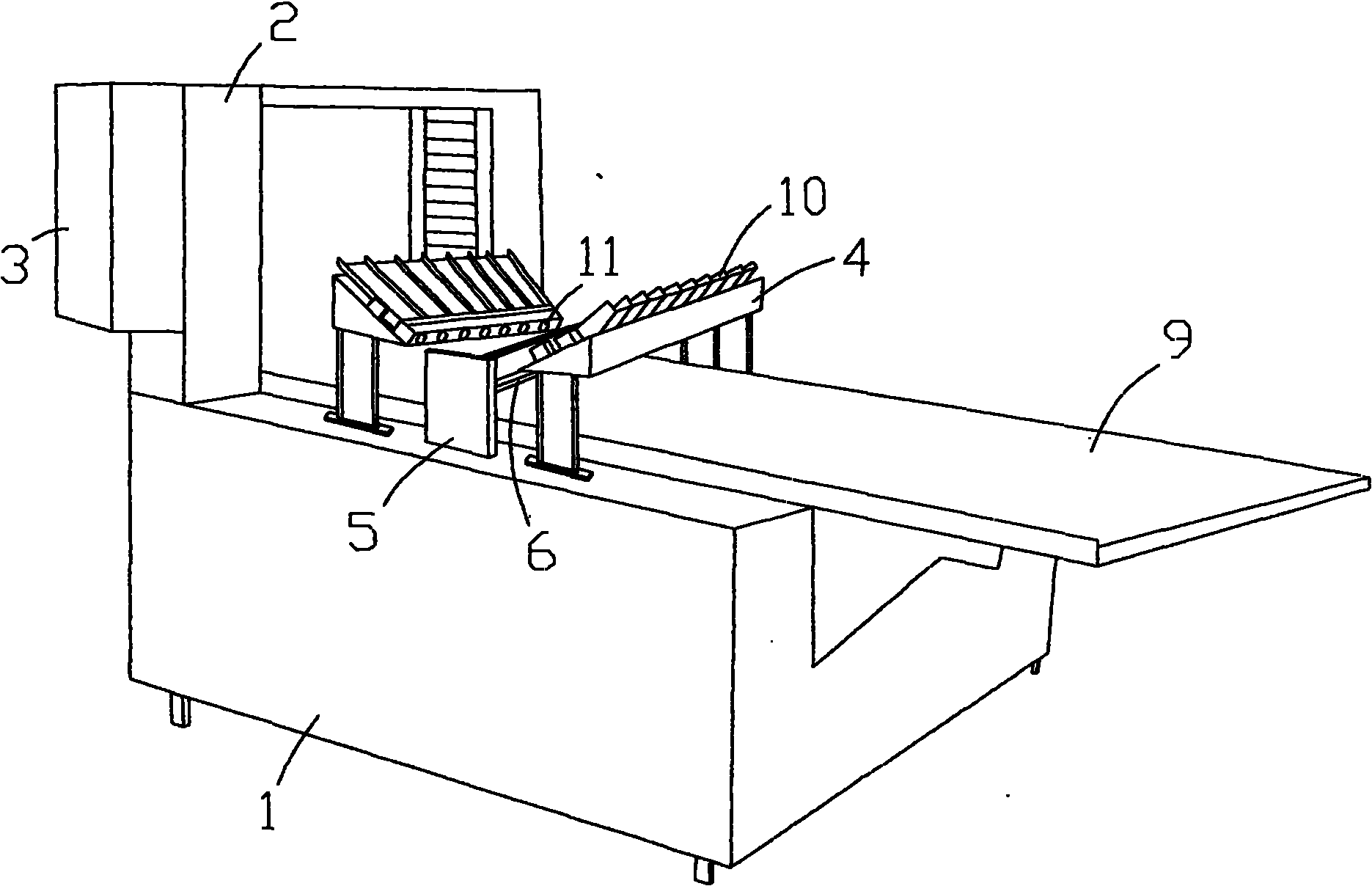

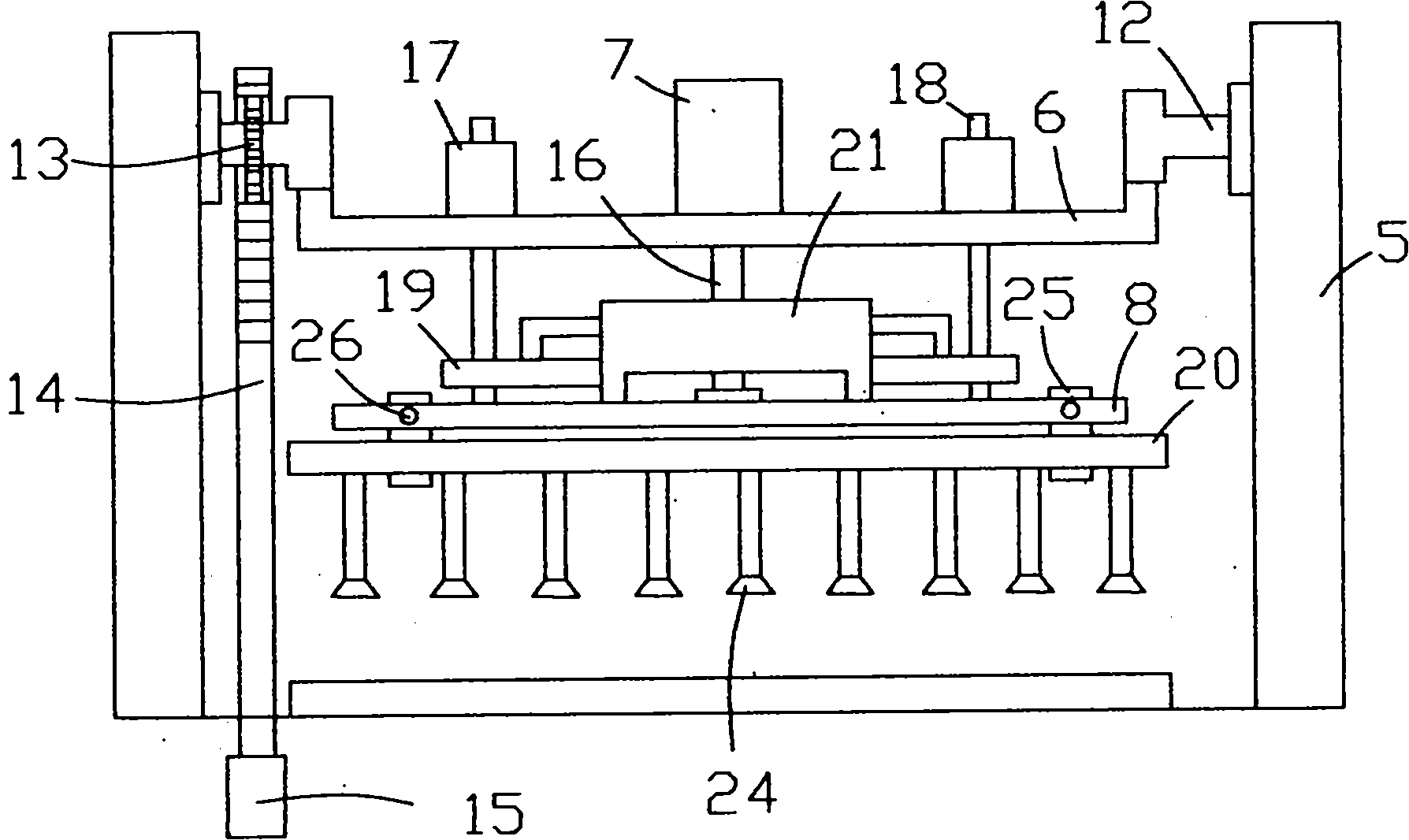

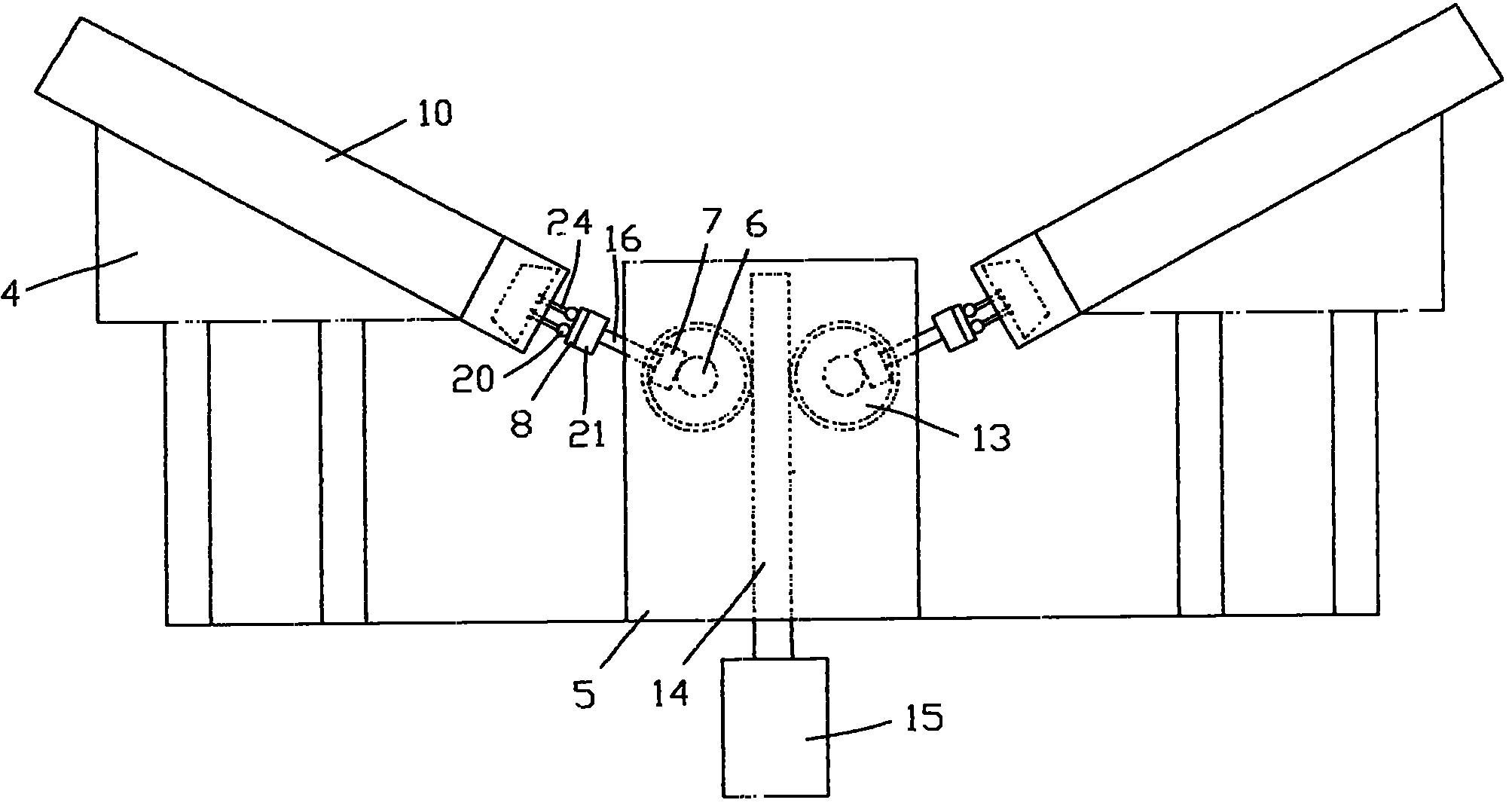

[0022] Embodiment 1, with reference to Figure 1~6 As shown, a fully automatic paper tray machine includes a base 1, a baking tray rack 2, a control box 3, a paper bracket 4, a bracket 5, a beam 6, a lifting cylinder 7, and a mounting plate 8. Conveyor belt 9 is arranged above, and grill frame 2 is welded on one end of machine base 1, and a side of grill frame 2 is provided with control box 3, is used for the action control of whole machine. Both the paper bracket 4 and the support 5 are arranged at the upper middle position of the base 1, wherein the number of the paper bracket 4 is 2 and symmetrically arranged on both sides of the bracket 5, and the bracket 5 is arranged on both sides of the base 1 . The upper end of the paper holder 4 is designed as a triangle, and the included angle between the hypotenuse of the triangle and the horizontal direction is between 35° and 45°. On the inclined surface of the upper end of the paper holder 4, there are at least one paper holder...

Embodiment 2

[0027] Embodiment 2, with reference to Figure 7 As shown, this embodiment is a further improvement of the above-mentioned embodiment 1. The clamping cylinder 21 is directly connected to the lifting cylinder 7 through the suspension rod 16, and the clamping cylinder 21 and the beam 6 are perpendicular to each other. Both ends are provided with clamping guide rods 23 , the bottom ends of the clamping guide rods 23 are fixed on the clamping plate 19 , and the air pipe 20 is fixedly connected directly under the clamping plate 19 . In this way, the mounting plate 8, the chute 22, the clamping slide seat 25 and the clamping slide bar 26 can be directly omitted. Compared with the above-mentioned embodiment 1, this embodiment has the characteristics of simpler structure and higher efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com