Drying method of karzai powder and drying device thereof

A technology of a drying device and a drying method, which is applied in the directions of drying solid materials, drying solid materials without heating, and drying. Good taste and taste, automatic and fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described through embodiment now in conjunction with accompanying drawing.

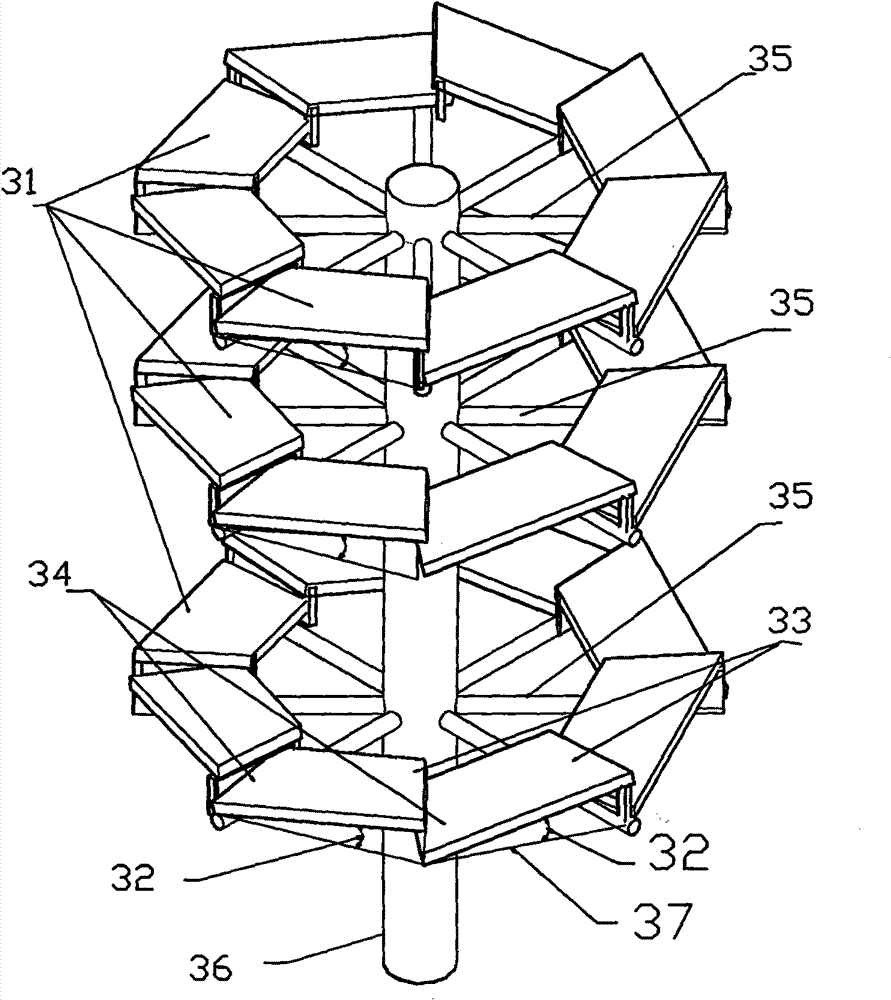

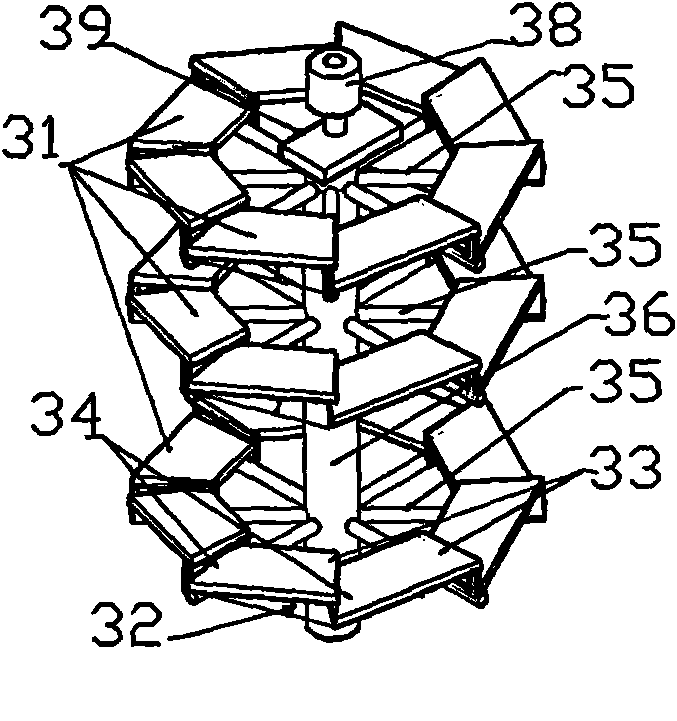

[0014] The drying method of the present invention is to utilize around the rotating shaft to connect several pallet racks whose surfaces are inclined downward from one end along the rotating direction of the rotating shaft in the tangential direction of the rotating shaft, so that each powder placed on the several pallet racks When the rotating shafts rotate, they are not blocked from each other and can obtain a larger area of air volume. Simultaneously, a vibrating device is arranged on the rotating shaft or the pallet frame to quickly dry the powder placed on the pallet frame through vibration and rotation.

[0015] Such as figure 1 As shown, the vertical rotating shaft 36 driven by the driving device is connected with three layers of support layer frames 35 up and down, and each layer of support layer frame 35 is composed of several tray frames 31 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com