Processing device for biodegradable high-barrier plastic film material

A plastic film, biodegradable technology, applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., to achieve the effect of fast drying and convenient fixing of the film base film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

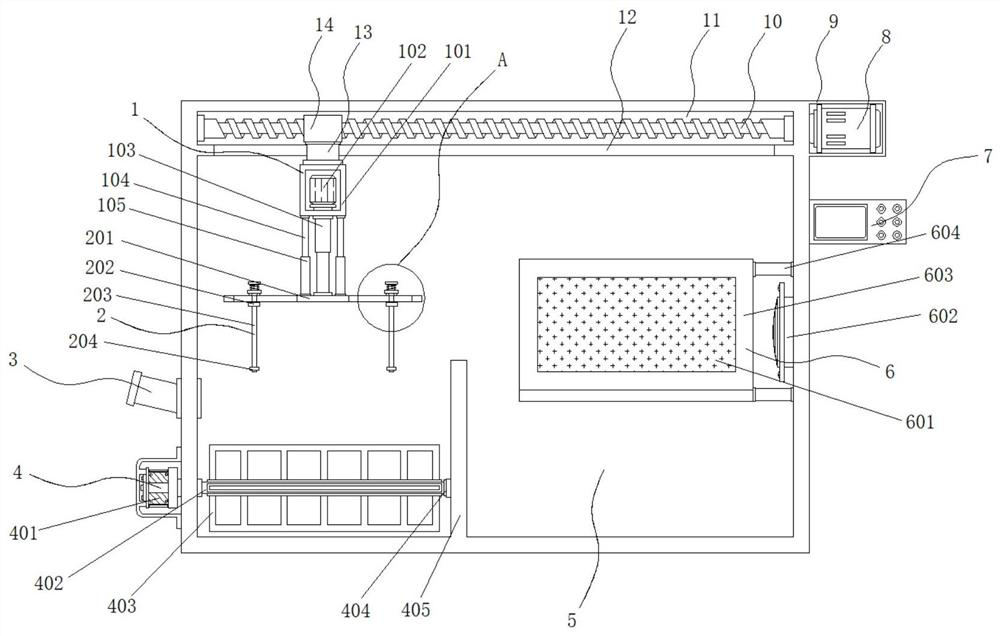

[0035] Example 1: See Figure 1-6, a processing device for biodegradable high-barrier plastic film materials, comprising a feed pipe 3 and a box body 5, one side of the box body 5 is fixedly connected with the feed pipe 3, and the top inside the box body 5 is provided with a soaking mechanism 1, The bottom end of the soaking mechanism 1 is provided with a clamping structure 2, one side of the inner bottom of the box body 5 is provided with a stirring mechanism 4, one side of the inner side of the box body 5 is provided with a drying mechanism 6, and one side of the box body 5 is fixedly connected with a Control board 7, one end of box body 5 is inlaid with groove 15, and the both sides of box body 5 one end are respectively fixedly connected with a group of sliding sleeve 16, and the inside of sliding sleeve 16 is connected with cover 17 flexibly, and the top of box body 5 is provided with Drive mechanism;

[0036] see Figure 1-6 A processing device for biodegradable high-b...

Embodiment 2

[0039] Embodiment 2: Soaking mechanism 1 is made up of installation box 101, cylinder 102, telescopic rod 103, limit rod 104 and limit tube 105, and installation box 101 is fixedly connected to the bottom end of connection block 13, and the inside of installation box 101 is fixedly connected There is a cylinder 102, the model of the cylinder 102 is SC50, the output end of the cylinder 102 runs through the bottom end of the installation box 101 and extends to the bottom end of the installation box 101, and a telescopic rod 103 is fixedly connected, and the two sides of the bottom end of the installation box 101 are respectively fixedly connected There is a group of limit rods 104, and the outside of the limit rods 104 is connected with a limit cylinder 105;

[0040] The center line of the telescopic rod 103 is on the same vertical plane as the center line of the installation box 101, and the center line of the installation box 101 is on the same vertical plane as the center line...

Embodiment 3

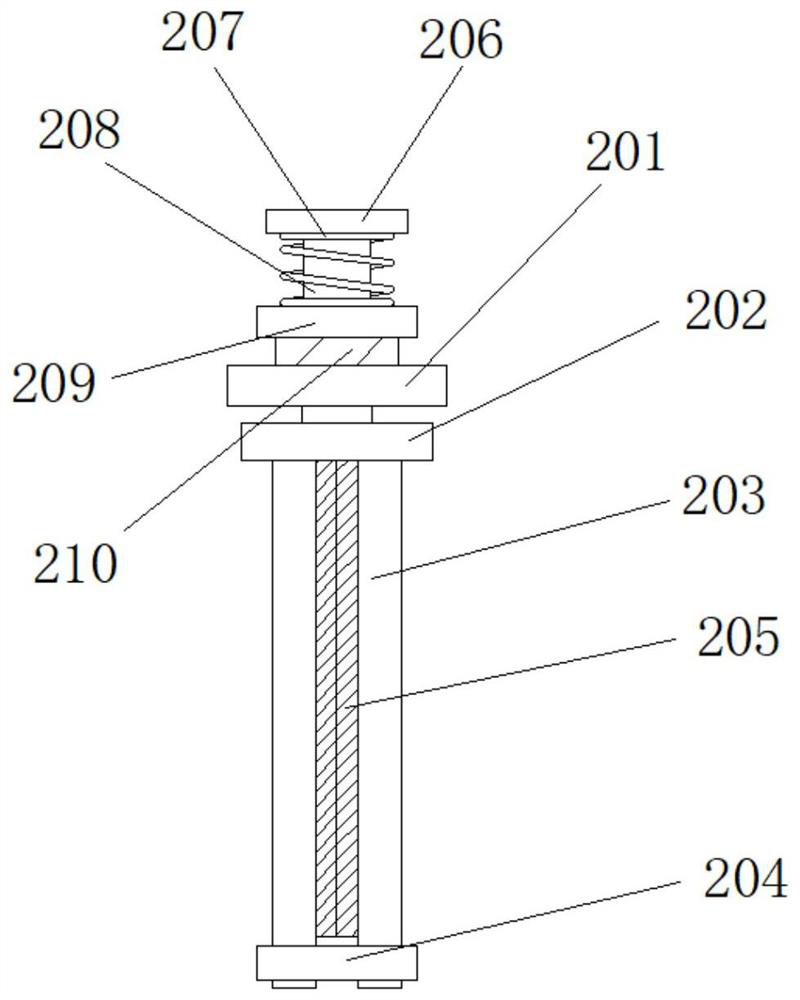

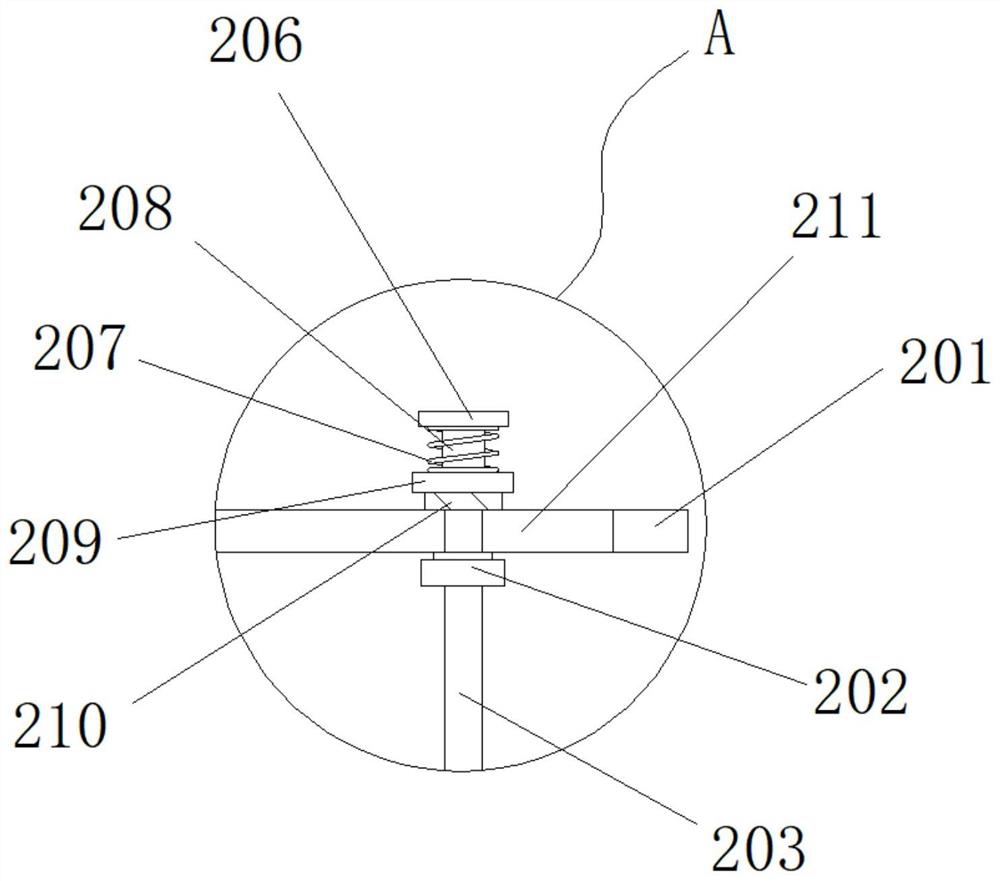

[0042] Embodiment 3: The clamping structure 2 consists of a fixed plate 201, a chute 202, a clamping rod 203, a ferrule 204, an anti-skid pad 205, a top plate 206, a spring 207, a connecting rod 208, a push plate 209, a friction pad 210 and a through groove 211 The fixed plate 201 is arranged at the bottom of the soaking mechanism 1, and a set of through grooves 211 are respectively inlaid on both sides of the top of the fixed plate 201. The inside of the through groove 211 is movably connected with a connecting rod 208, and the top of the connecting rod 208 is fixedly connected with a top plate. 206, the bottom end of the top plate 206 is fixedly connected with a spring 207, the bottom end of the spring 207 is fixedly connected with a push plate 209, the bottom end of the push plate 209 is fixedly connected with a friction pad 210, the friction pad 210 is movably connected with the fixed plate 201, and the connecting rod The bottom end of 208 is fixedly connected with chute 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com