Wheel section steel rim rolling machine

A type of steel and rim roll technology, which is applied to rims, vehicle parts, transportation and packaging, etc., can solve the problems of roll deviation, demoulding, deformation, etc., to prevent deviation, improve the stress situation, and arrange reasonable and compact layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

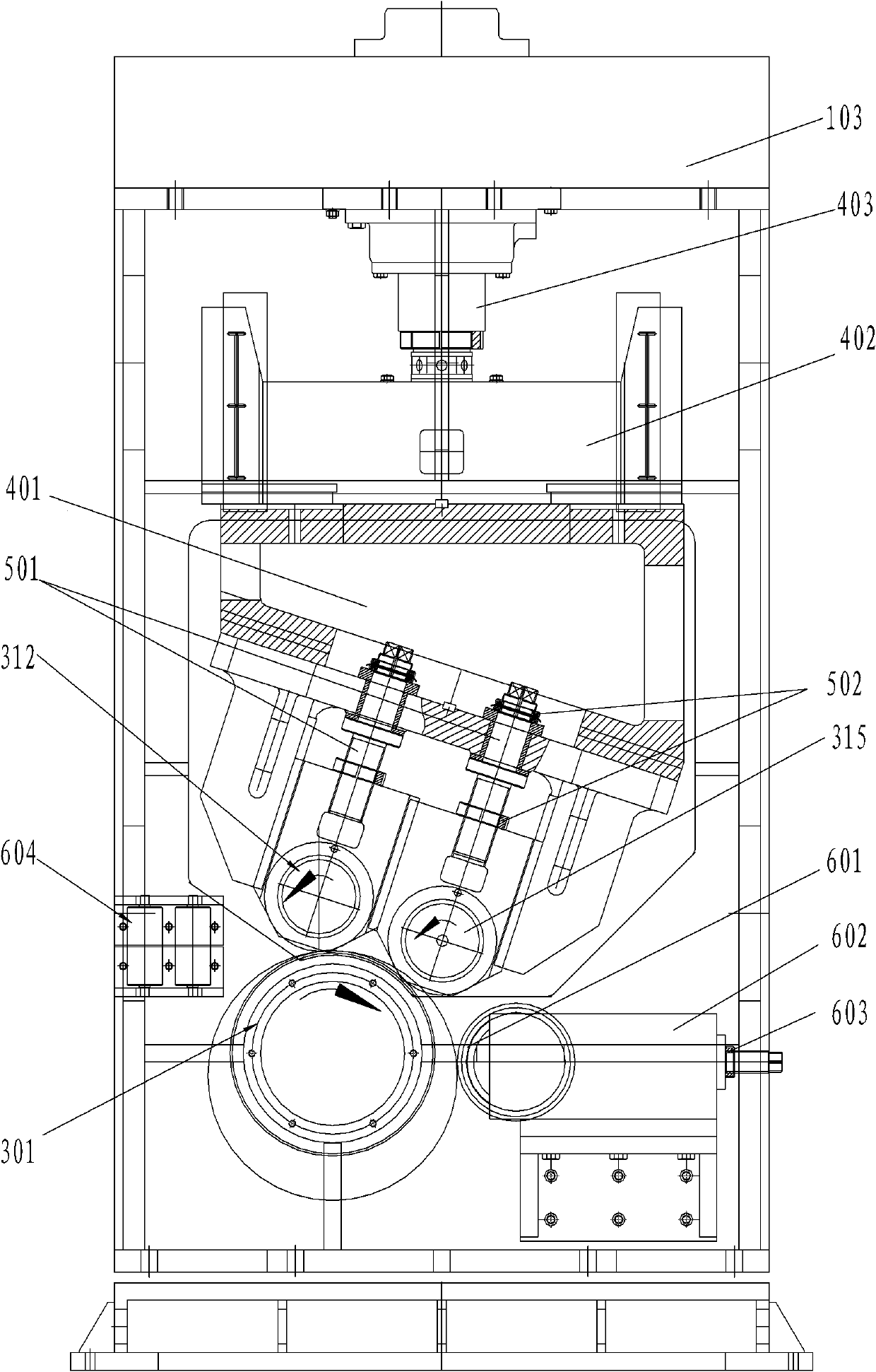

[0018] The support of the above structure can be arranged as a gantry-type vertical structure, or as a horizontal horizontal structure.

[0019] Present embodiment is described with the vertical structure of gantry type.

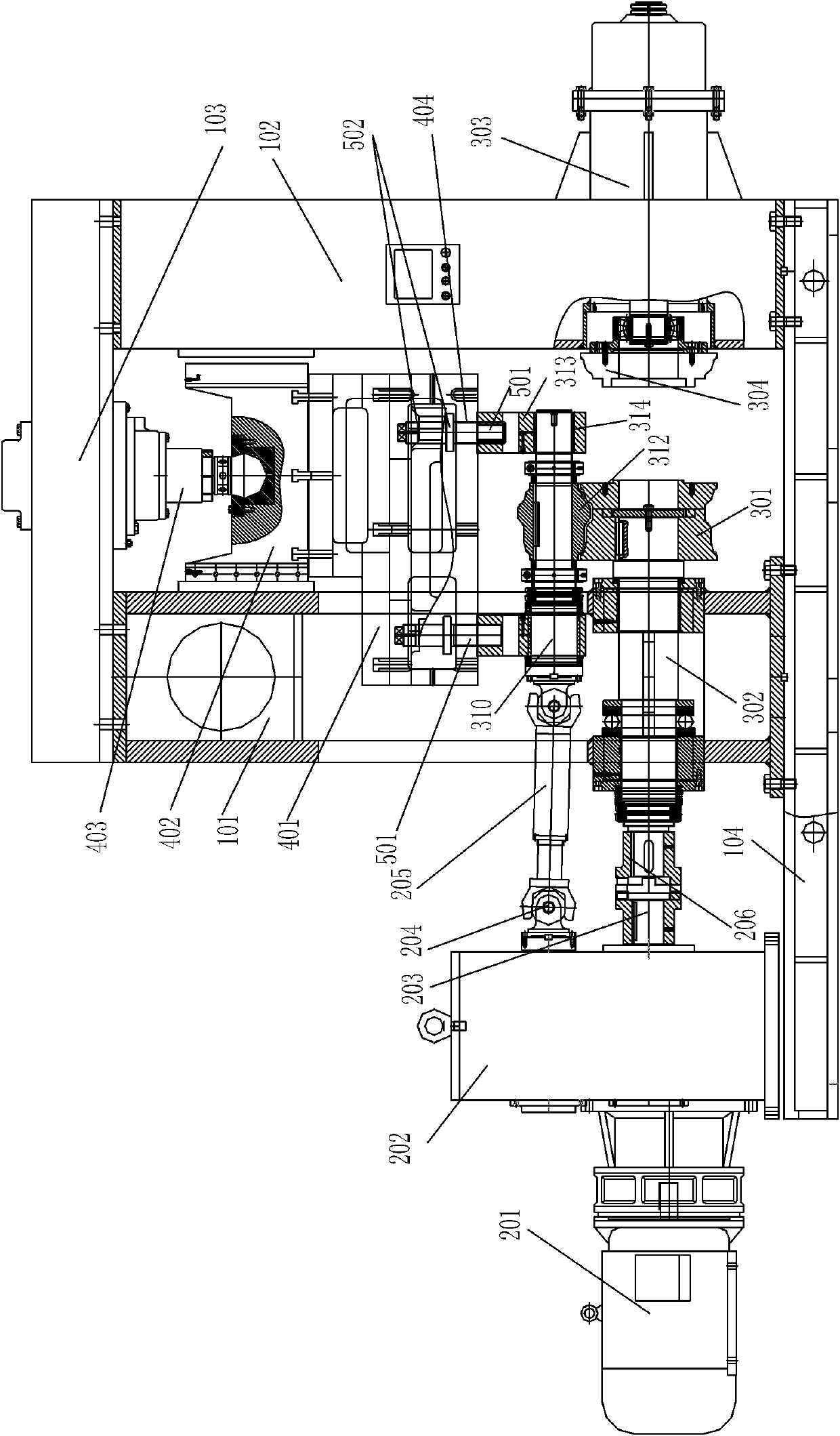

[0020] Such as figure 1 As shown, the support includes two columns 101, 102, and a top beam 103 is arranged on the top of the two columns. The columns 101 , 102 are connected to the base 104 . A motor 201 is connected to the base 104, and the output shaft of the motor 201 is connected to a reduction transmission box 202. The reduction transmission box 202 can be a gear reduction box with three output shafts, two output shafts 203 and 204 are shown in the figure.

[0021] The output shaft 203 is connected with the roller shaft 302 of the circular concave roller mold 301 of the shaped steel rim rim through the shaft coupling 206; the roller shaft 302 passes through the column 101 and is supported by it. The shape of the shaped steel rim circle concave rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com