Vacuum heat sealing machine applicable to vacuum insulation panel

A technology of vacuum heat insulation board and vacuum heating, which is applied in the directions of packaging sealing/fastening, external support, transportation packaging, etc., which can solve the problems of reducing the air escape time in the bag, so as to ensure airtightness, improve work efficiency, and speed up Effect of Vacuum Speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

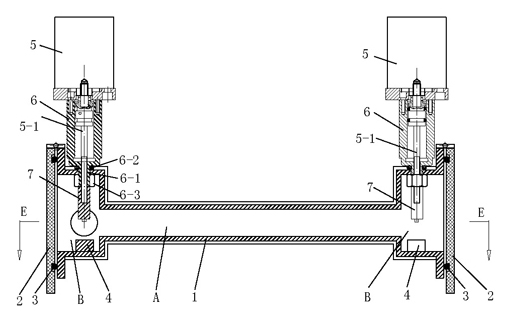

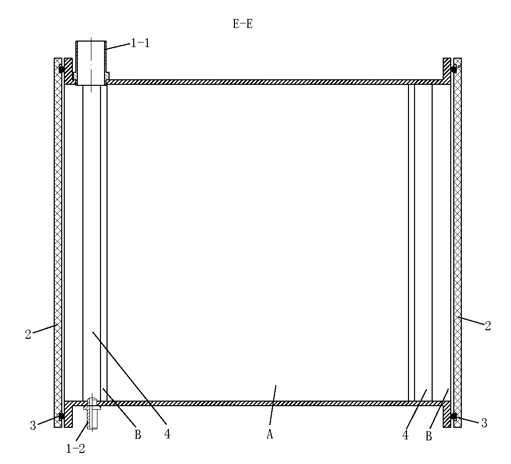

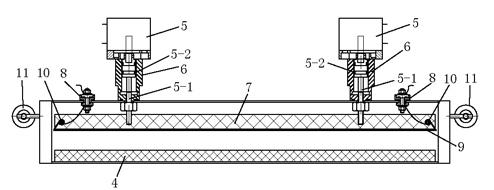

[0017] A vacuum heat sealing machine suitable for vacuum heat insulation panels shown in the accompanying drawings has a box body 1, the two ends of the box body 1 are connected, and the middle part of the box body 1 is a vacuum chamber A for placing a vacuum heat insulation panel. The end is the vacuum heat-sealing chamber B, the middle part of the box body 1, that is, the part corresponding to the vacuum chamber A, is flat, and the parts corresponding to the vacuum heat-sealing chamber B at both ends expand upward and downward, forming a symmetrical special-shaped box body at both ends. Cover plates 2 are respectively hinged on the openings at both ends of the box body 1, and the two cover plates 2 are plexiglass cover plates, which are convenient for observing the situation in the vacuum heat-seal chamber B. A cover plate sealing gasket 3 is provided on the inner side of the cover plate 2 . Two transition cylinders 6 and two double-layer sealing electrodes 8 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com