Powder feeding device

A feeding device and powder technology, which is applied in the field of machinery, can solve the problems of discontinuous cutting, easy bonding of blades, and easy arching of the square tube section, so as to reduce the possibility and achieve the effect of smooth cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

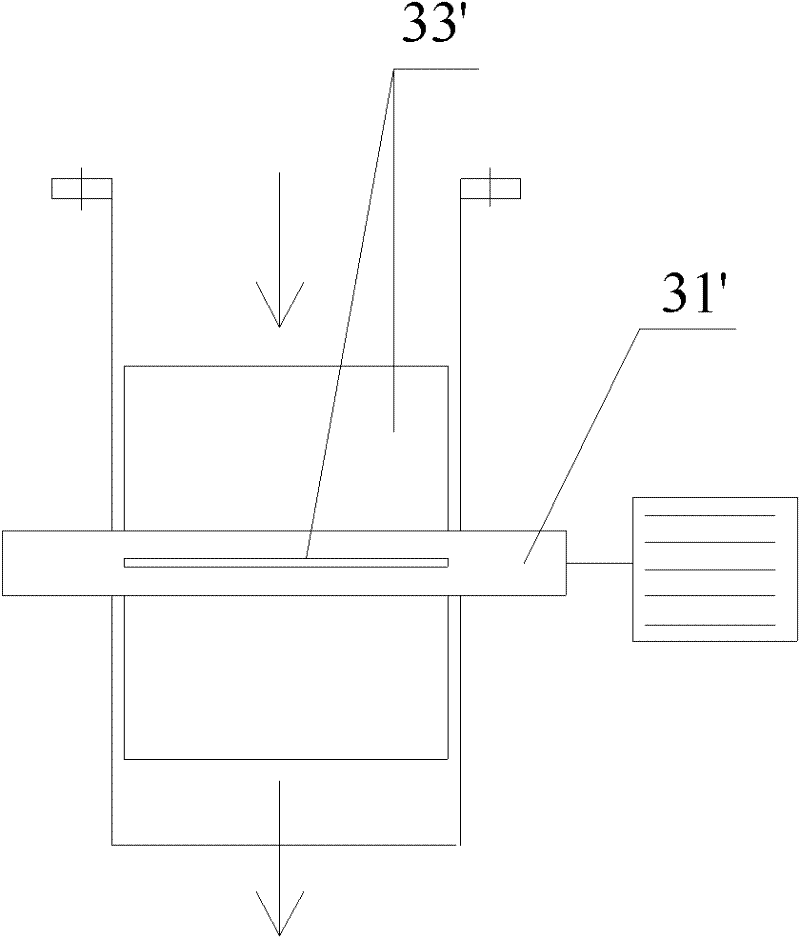

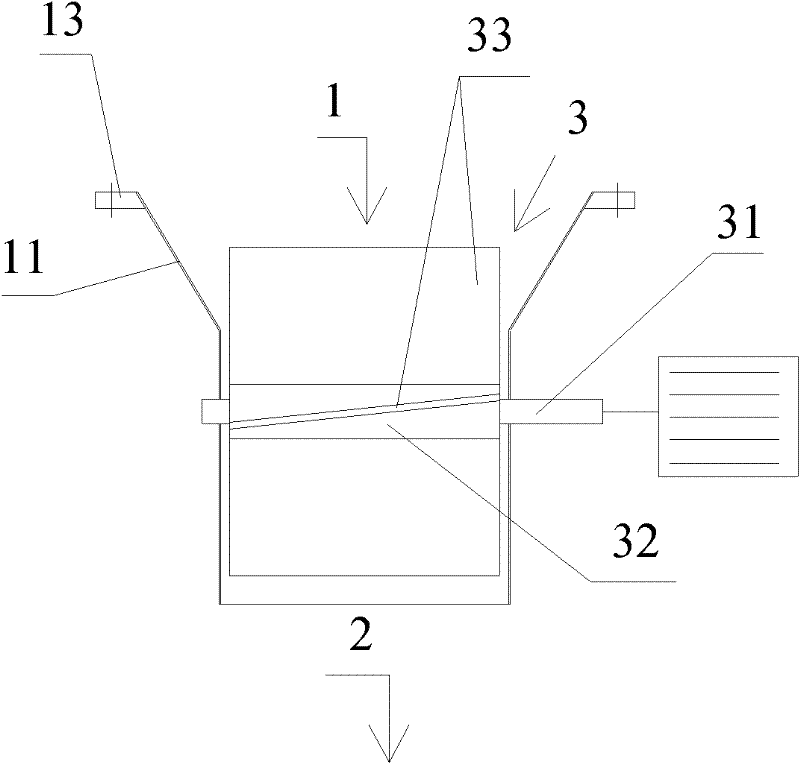

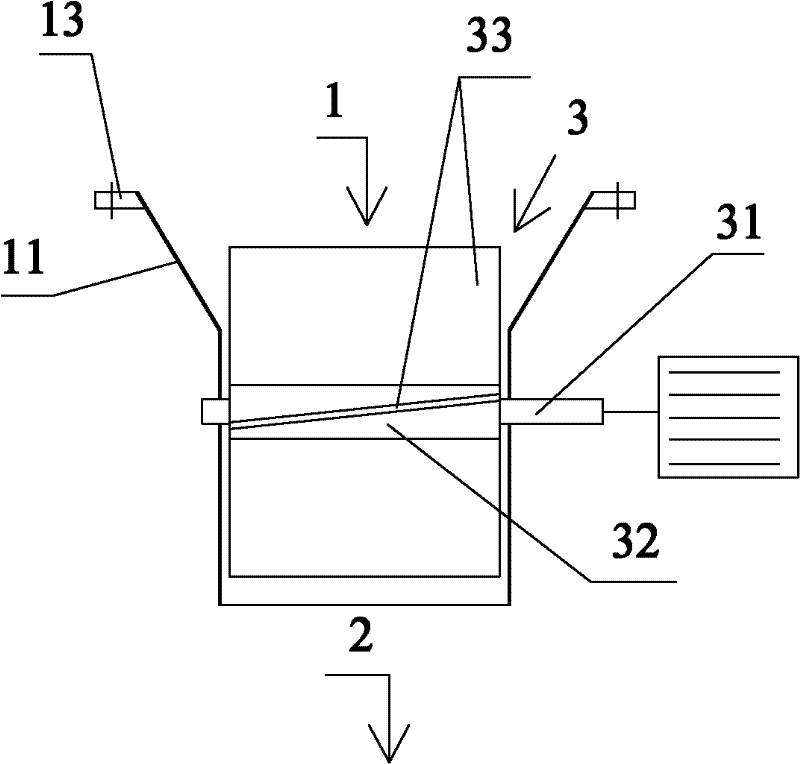

[0017] figure 2 A schematic structural view of the powder feeding device according to the present invention is shown. Such as figure 2 As shown, the powder feeding device includes: a housing with an inlet 1 and an outlet 2, an impeller 3 arranged in the housing, and a driving device for driving the impeller. In this embodiment, the driving device uses a motor to reduce the speed All-in-one machine. The casing includes a funnel part 11 , the impeller 3 is located at the lower part of the funnel part 11 , and the blades 33 of the impeller 3 at least partly extend upwards into the inclined discharge area of the funnel part 11 . The funnel makes it difficult for the powder to arch when feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com