A kind of preparation method of cellulose acetate open-pore microporous foaming material filter tip adsorption rod

A technology of microporous foaming material and cellulose acetate, which is applied in the fields of e-liquid filter element, application, food science, etc., can solve the problems that are difficult to be widely used and difficult to melt process, and achieve low price, good smoke interception effect, Effects that increase the chance of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Prepare materials according to the following components by mass, and mix them to obtain a mixed material:

[0026] 99 parts of cellulose triacetate, 1 part of polypropylene, 1 part of triethyl citrate, 5 parts of sodium carbonate, 4 parts of phosphite additives;

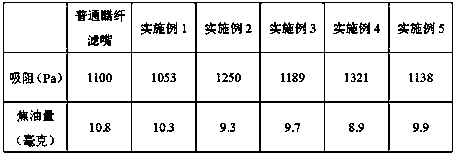

[0027] (2) Adopt a conventional twin-screw extrusion foam molding unit, control the inlet temperature to 150°C, the temperature in the first stage to 175°C, the temperature in the second stage to 185°C, the temperature in the third stage to 195°C, and the temperature in the fourth stage to 200°C, the temperature of the fifth stage is 185°C, and the temperature of the die is 150°C. Add the mixture obtained in step (1), and then add 10 parts by mass of supercritical carbon dioxide in the second stage to extrude into a circular mold. , foaming at 240° C. for 5 minutes after extrusion to obtain filter adsorption sticks of cellulose acetate open-cell microporous foaming material. Adding the obtained round adso...

Embodiment 2

[0029] (1) Prepare materials according to the following components by mass, and mix them to obtain a mixed material:

[0030] 70 parts of cellulose diacetate, 30 parts of polypropylene, 1 part of AC foaming agent;

[0031] (2) Adopt a conventional twin-screw extrusion foam molding unit, control the inlet temperature at 175°C, the temperature at the first stage at 185°C, the temperature at the second stage at 195°C, the temperature at the third stage at 200°C, and the temperature at the fourth stage at 195°C, the temperature of the fifth section is 195°C, and the temperature of the die is 185°C. Add the mixed material obtained in step (1), and then add 1 mass part of supercritical carbon dioxide in the second section to extrude into a triangular mold. After extrusion, foam at 200° C. for 1 min to obtain a cellulose acetate open-pore microporous foam material filter adsorption rod. The obtained triangular adsorption stick is added to the filter to prepare cigarettes, and the ta...

Embodiment 3

[0033] (1) Prepare materials according to the following components by mass, and mix them to obtain a mixed material:

[0034] 75 parts of cellulose acetate, 25 parts of polypropylene, 1 part of tributyl citrate, 3 parts of sodium bicarbonate foaming agent, 1 part of phosphite additive;

[0035] (2) Adopt a conventional twin-screw extrusion foam molding unit, control the inlet temperature at 165°C, the temperature at the first stage at 170°C, the temperature at the second stage at 190°C, the temperature at the third stage at 195°C, and the temperature at the fourth stage at 200°C, the temperature of the fifth stage is 190°C, and the temperature of the die is 175°C. Add the mixture obtained in step (1), and then add 5 parts by mass of supercritical carbon dioxide in the second stage to extrude into a pentagonal mold. After extrusion, it is foamed at 230° C. for 2 minutes to obtain a filter adsorption rod of cellulose acetate open-cell microporous foam material. Adding the obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com