Two-gear type stitch length adjusting device of sewing machine

An adjustment device and two-stop technology, which is applied in the direction of sewing machine components, sewing equipment, cloth feeding mechanism, etc., can solve the problem that the stitch distance adjustment mechanism cannot meet the market demand, etc., and achieve convenient stitch distance adjustment, wide application and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

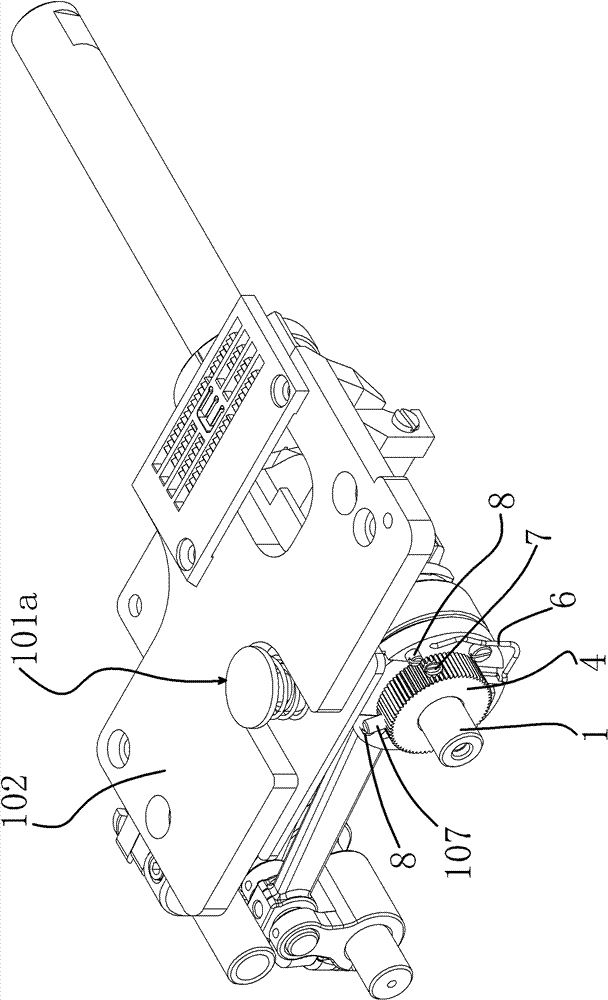

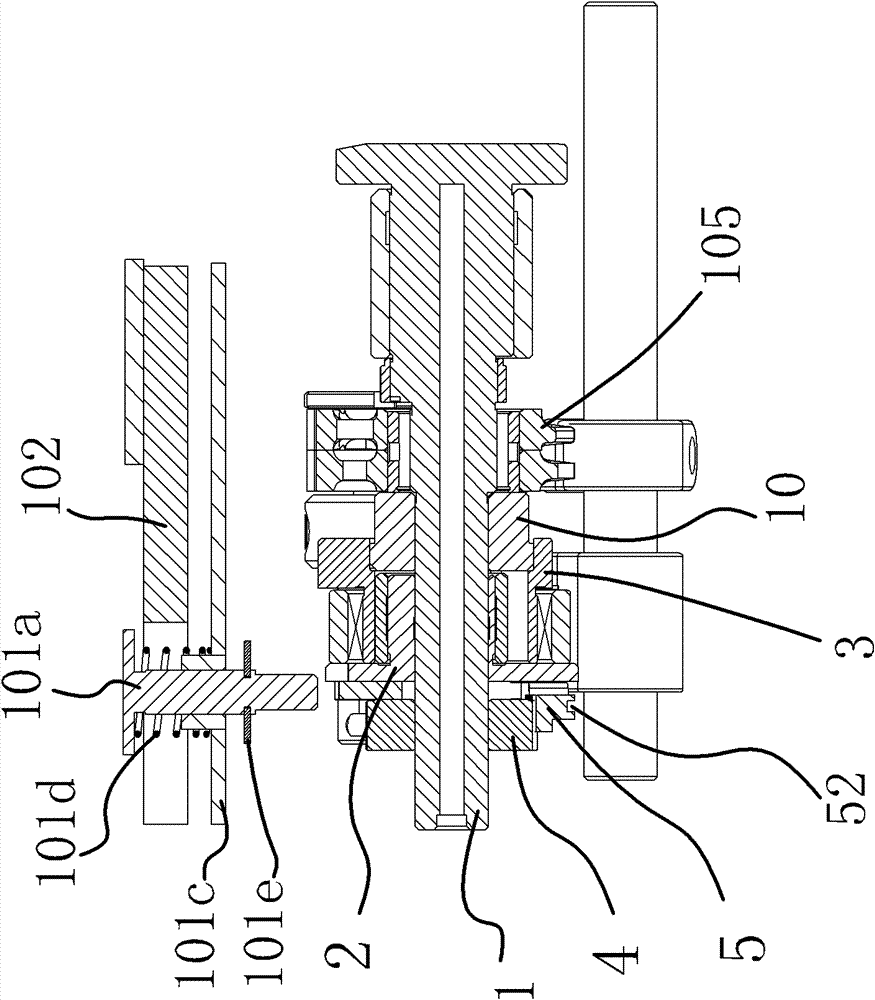

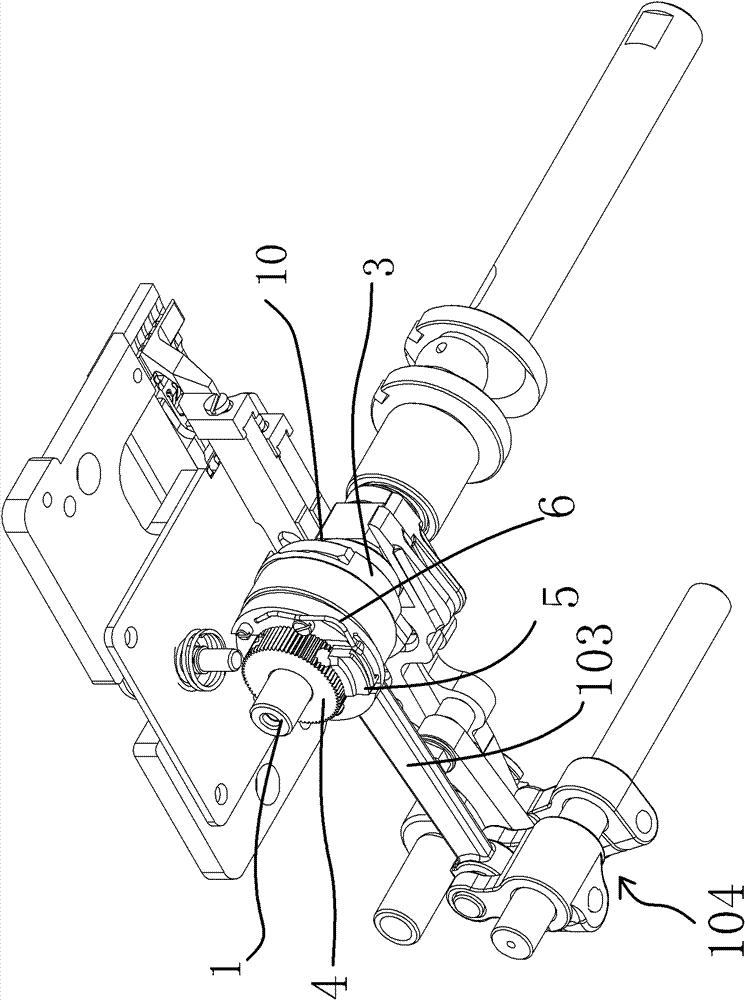

[0040] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the two-speed stitch adjustment device of the sewing machine of the present invention is arranged on the lower shaft 1, and includes a stitch adjustment wheel 2, a stitch adjustment ratchet 4, a stitch adjustment slider 5, an elastic positioning structure, a limit structure, Eccentric sleeve 9, cloth feeding cam 3, guiding mechanism and operating components.

[0041] Such as Figure 5 and Figure 6 As shown, the needle gauge adjustment wheel 2 includes a first stage 21 and a second stage 22. The first stage 21 is a cylindrical eccentric wheel, and the end surface of the second stage 22 is provided with a chute 22c perpendicular to the centerline. On the outer peripheral surface of the stage two 22, there is an open groove 22d along its axial direction, the open groove 22d is located at one end of the chute 22c and communicates with the chute 22c, and the bottom of the open groove 22d is provided with a...

Embodiment 2

[0058] This embodiment is similar in structure and function to Embodiment 1, wherein the inner side of the cloth feeding cam seat 10 has a positioning surface 1, and the lower shaft 1 is correspondingly provided with a positioning surface 2 cooperating with the positioning surface 1. The cloth feeding cam seat 10 forms a fixed connection with the lower shaft 1 through the matching positioning surface 1 and positioning surface 2, and two V-shaped scoring lines 10c are engraved on the connecting section 10b of the cloth feeding cam seat 10, which are respectively aligned with the V-shaped scale Line 22e contrast is used for large and small gear selection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com