Transmission mechanism of multifunctional testing equipment for ignition lock

A multi-functional testing and transmission mechanism technology, applied in the direction of mechanical equipment, transmission devices, friction transmission devices, etc., can solve the problems of only longitudinal reciprocating movement, labor-intensive, time-consuming, etc., and achieve long-term stable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

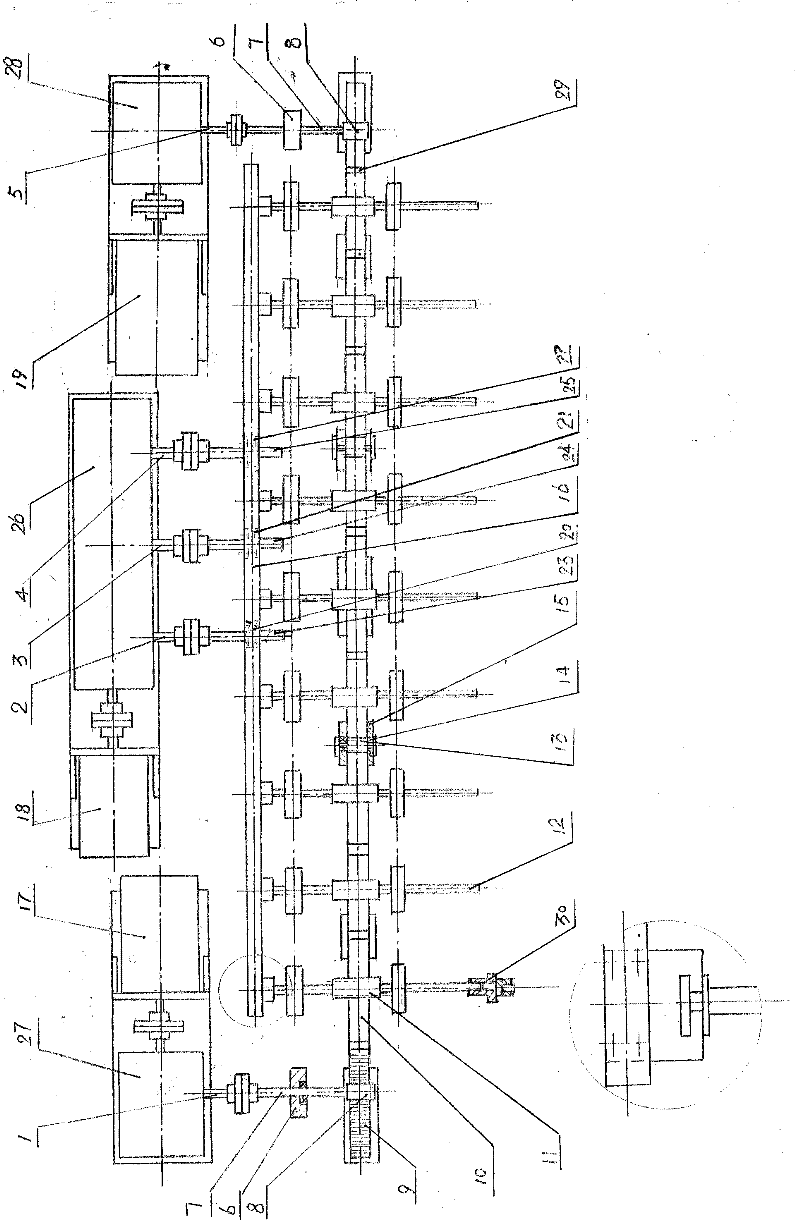

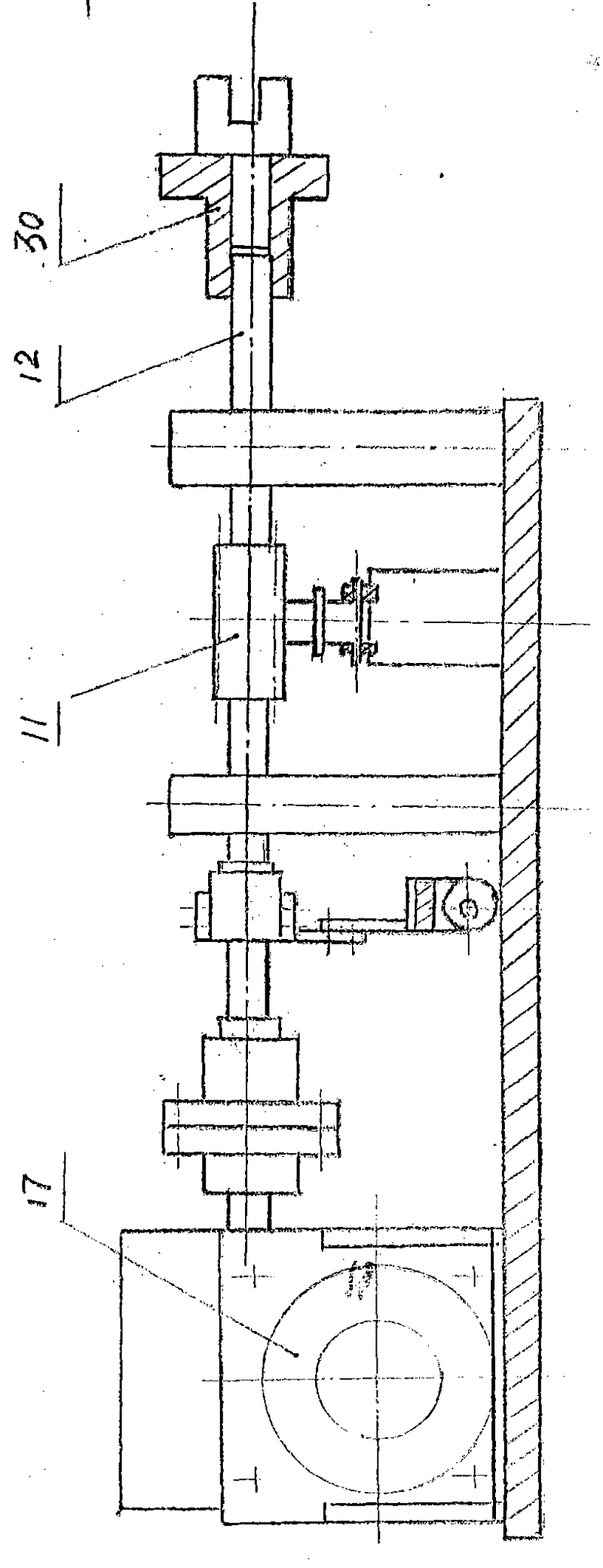

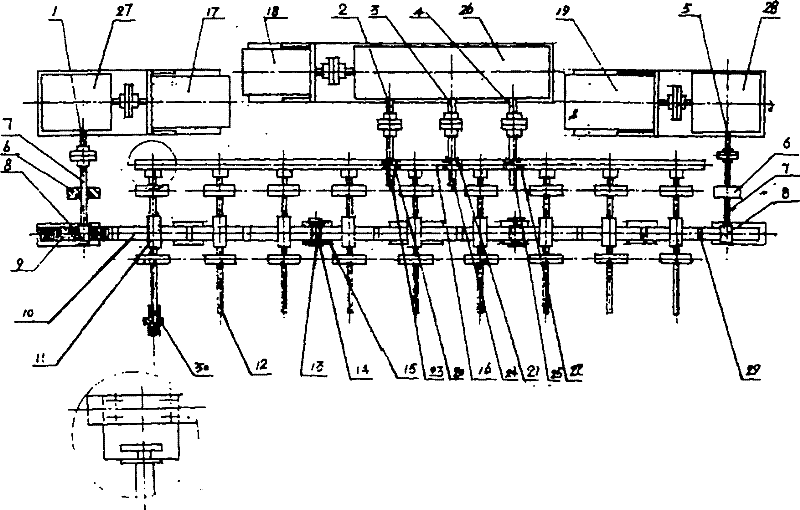

[0011] Example: see attached figure 1 to attach figure 2 , the transmission mechanism of the multifunctional ignition lock testing equipment, it comprises the first stepping motor 17 and the 3rd stepping motor 19, the first reduction box 27 that is connected with the output shaft of the first stepping motor 17, and the The third reduction box 28 connected to the output shaft of the third stepping motor 19 is in phase with the first output shaft 1 on the first reduction box 27 and the fifth output shaft 5 on the third reduction box 28. Connected gear shaft 7, the gear 8 that is arranged on the gear shaft 7, the second stepping motor 18, the three output shaft reduction box 26 that is connected with the output shaft of the second stepping motor 18, the three output shafts The first output shaft 2, the second output shaft 3, and the third output shaft 4 of the reduction box 26 are respectively connected with a first threaded screw mandrel 23, a second threaded screw mandrel 24,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com