Concrete cavity forming mold and use method thereof

A technology for forming molds and concrete, which is applied in the direction of molds, ceramic molding machines, mold fixing devices, etc. It can solve the problems of difficult design, installation and dismantling, large use limitations, and difficult cleaning, and achieves less demoulding workload and long-term use. Stable, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] Example 1 of Concrete Cavity Forming Mold

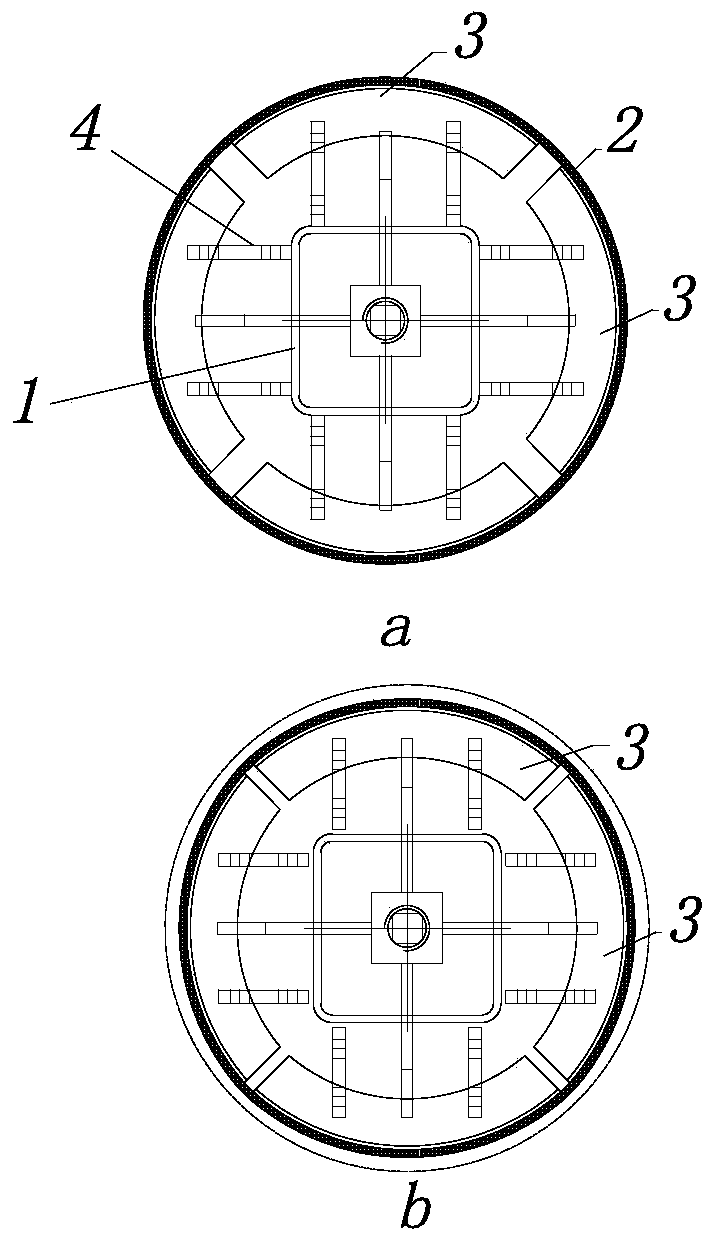

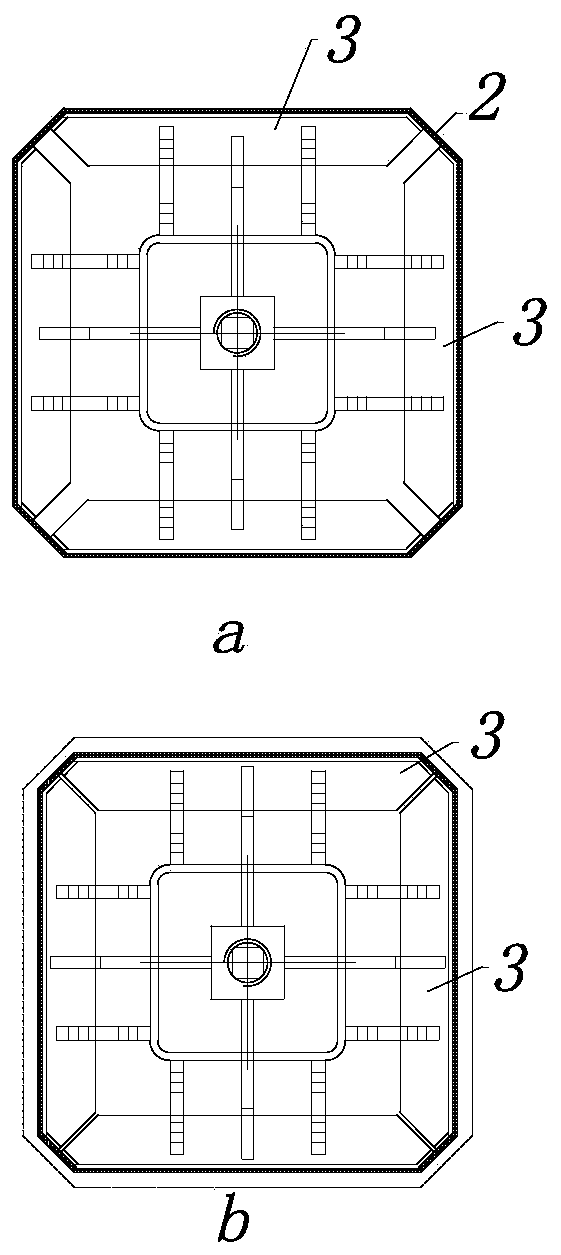

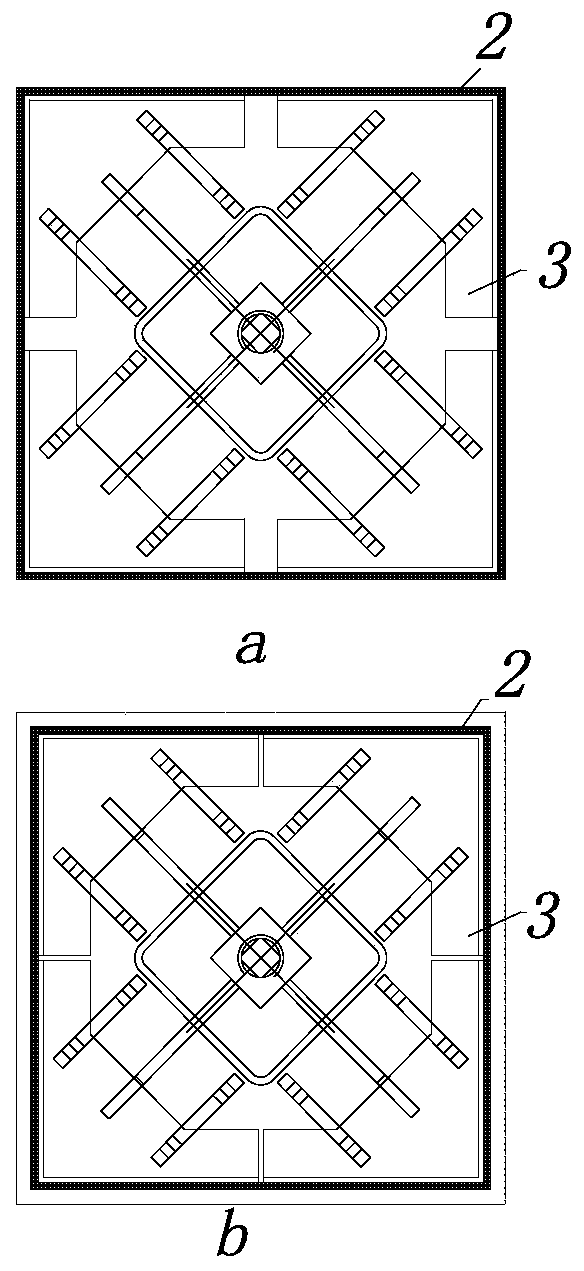

[0030] Figure 1 to Figure 4 An embodiment of the concrete cavity forming mold of the present invention is shown. The concrete cavity forming mold of this embodiment includes a telescopic skeleton 4, an elastic wrapping layer 2 and a plurality of support plates 3, and the plurality of support plates 3 surround the telescopic skeleton The telescopic skeleton 4 is arranged on the outer side of 4 and is connected with the supporting board 3 , and the elastic wrapping layer 2 is arranged on the outer side of a plurality of supporting boards 3 . Wherein, the elastic wrapping layer 2 can be, for example, a rubber layer, a silica gel layer or a steel plate layer, etc.; two of the multiple support plates 3 form a group, and the two support plates 3 in the same group are symmetrically arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com