Online automatic sampler of bonding sheet for copper-clad plate and sampling method thereof

A technology of automatic sampler and adhesive sheet, applied in the direction of sampling device, etc., can solve the problems of inaccurate sampling position, low sampling efficiency and high cost, so as to reduce the formation of unqualified products, improve work efficiency, and save manpower and material resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

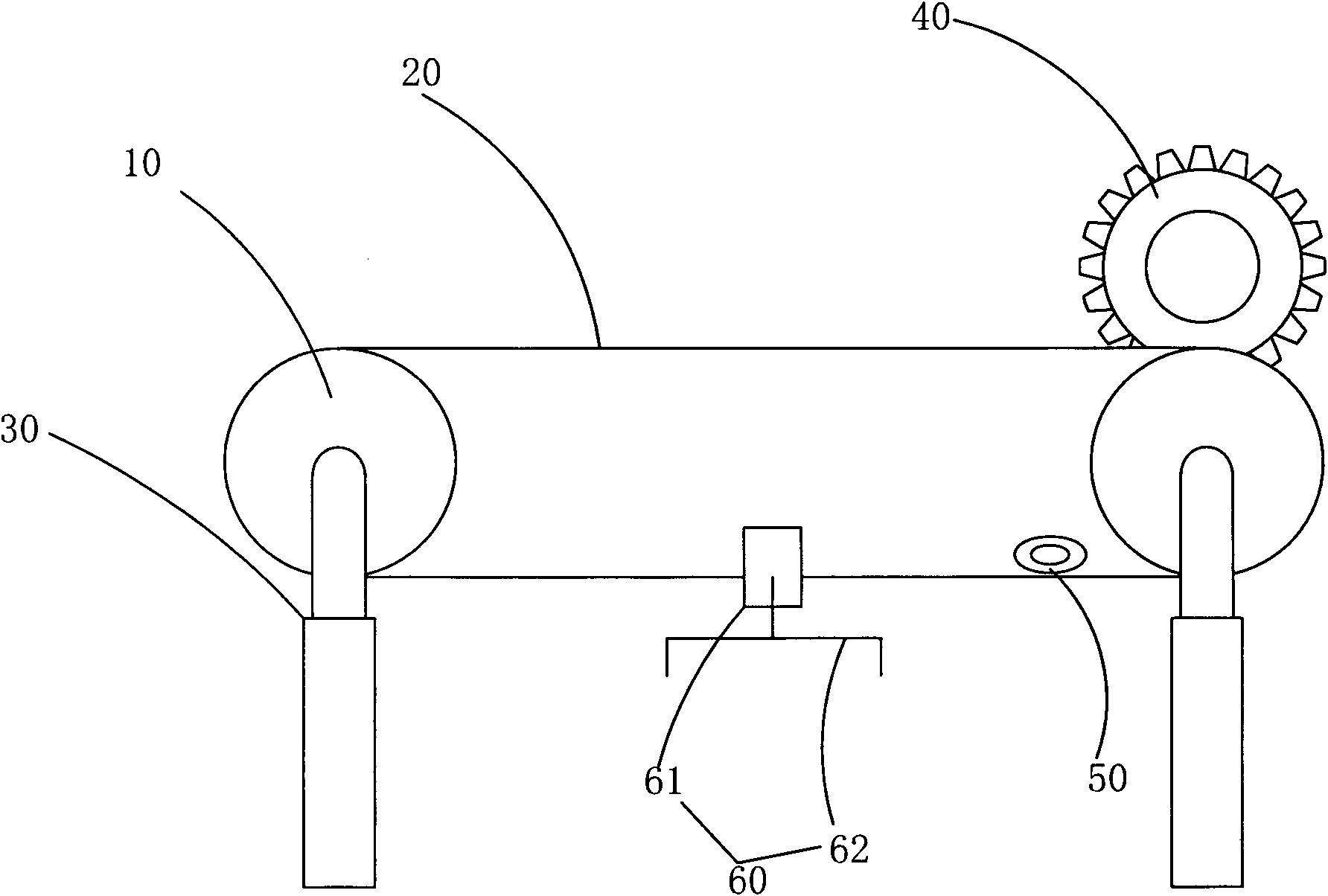

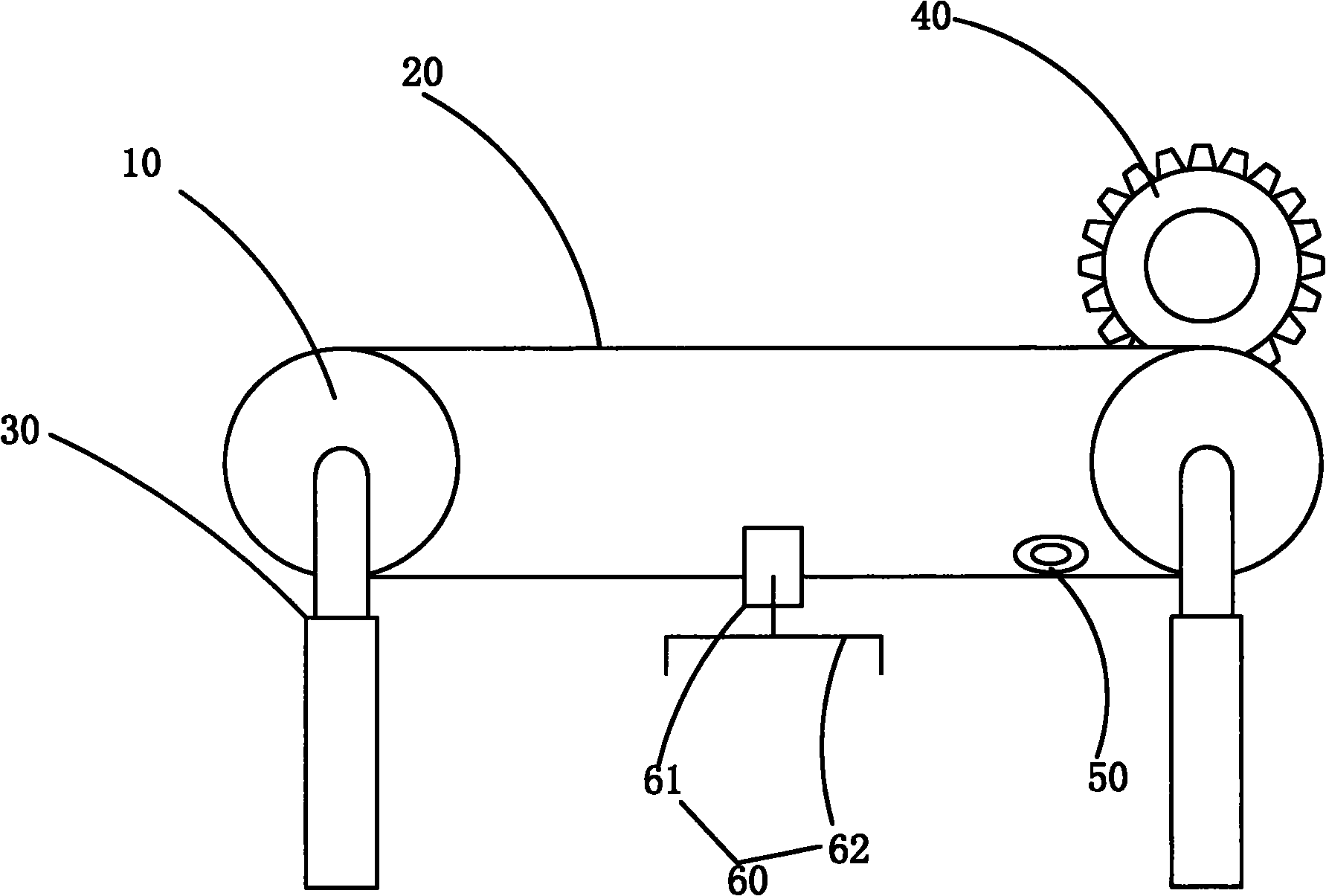

[0025] Such as figure 1 As shown, the on-line automatic sampler for bonding sheets for copper clad laminates of the present invention is used to be installed above the production transfer device for bonding sheets, which includes: several rollers 10 with different diameters, and a conveyor belt wrapped around the rollers 20. Lifting bracket 30, gear 40, induction electric eye 50 and sampling device 60. It also includes a circuit control system, and the electrical connection between the various components and the circuit control system is realized by prior art, and will not be repeated here.

[0026] The several rollers 10 are in the shape of a cylinder, and these several rollers 10 are respectively provided with a lifting bracket 3 correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com