Method for detecting channeling condition by static gelatinization strength of cement

A technique for measuring static gel strength and channeling, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, testing material strength by applying stable tension/pressure, and measuring the rate of increase and deceleration of fluid, etc., which can solve the problem of repeatability Poor performance, low downhole pressure, inability to simulate the flow state change process, etc., to achieve the effect of simple method and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention comprises the following steps:

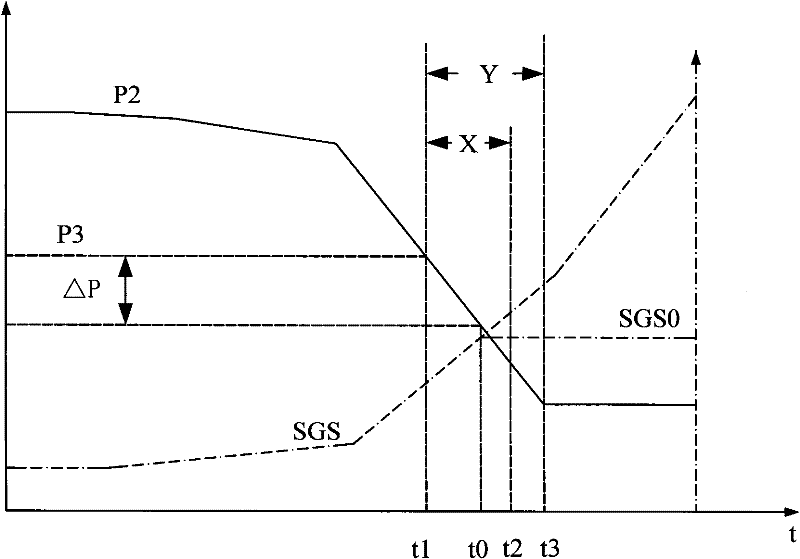

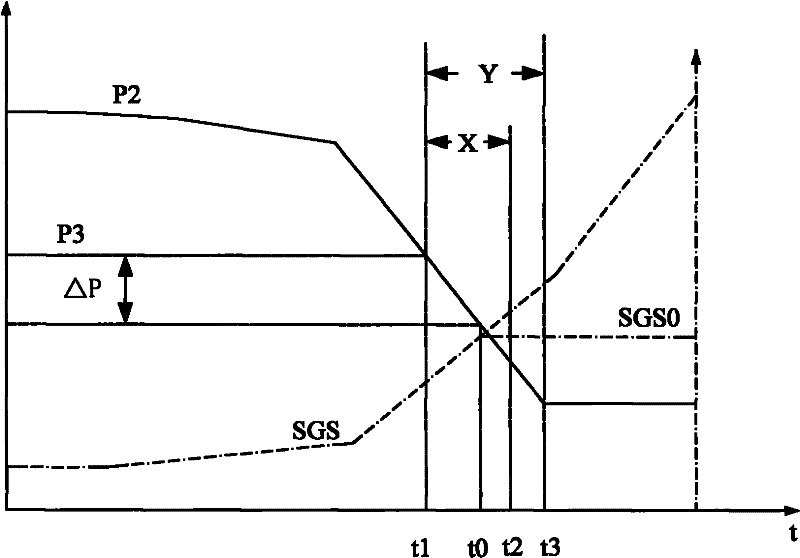

[0055] (1) Select the channeling well parameters of the cement slurry, and obtain the channeling point (namely, the time and position point of channeling measurement) and the channeling pressure ΔP of the cement slurry according to the channeling well and the parameters of the cement slurry. The change of static gel strength of cement slurry and the selection of measuring points are as follows: figure 1 As shown, the selection of the detection point and the setting of the detection pressure ΔP include the following steps:

[0056] (1.1) According to the annulus size of the channeling well and the length of the cement slurry sealing section, calculate the pressure loss value of the cement slurry P 1 :

[0057] P 1 = 4 × SGS × L ( D ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com