Screen printing electrode and application thereof

A technology of screen printing electrodes and electrodes is applied in the field of analytical instruments to achieve the effects of enhancing hydrophilicity, simple materials and high electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 1 mL of acetone and cyclohexanone and mix with each other, then add 0.02 g of cellulose acetate and stir until fully dissolved. Add 0.2 g of N-octylpyridine hexafluorophosphate and 0.8 g of graphite powder and stir until a homogeneous slurry is formed.

[0031] The slurry developed by the present invention can be printed by a common screen printing process.

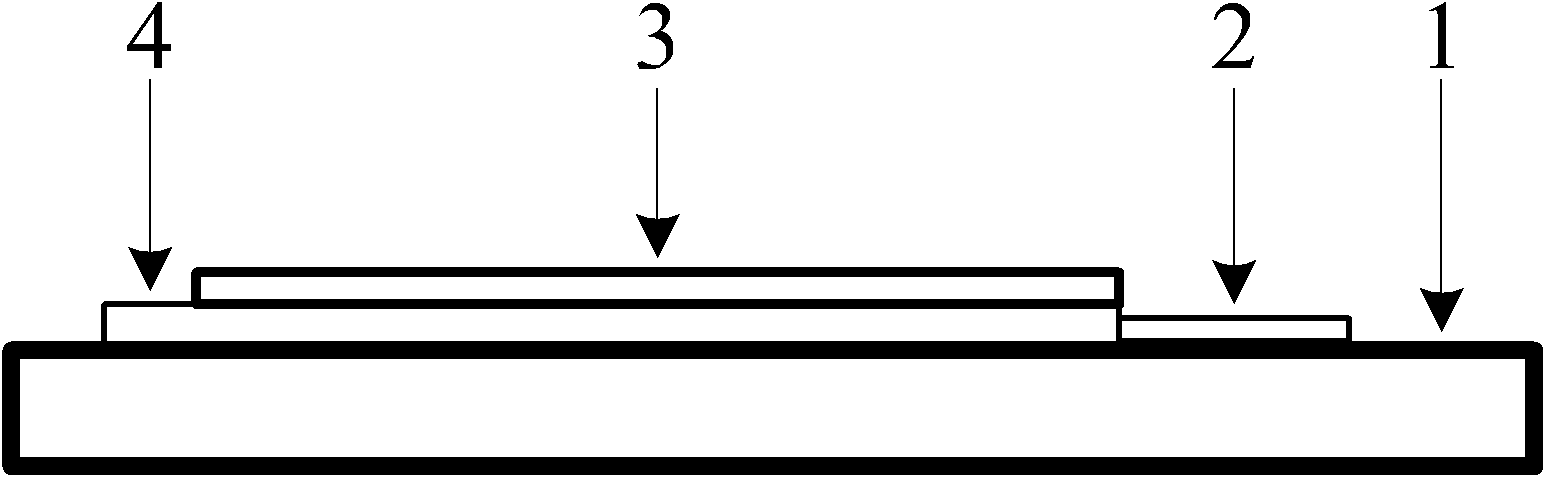

[0032] For electrode printing, first print the electrode leads on the polyvinyl chloride substrate, after drying the substrate, print the working electrode with the above-mentioned prepared paste, and place it in an oven after printing. Then place it at room temperature to cool. Finally, an insulating layer is printed to make a screen-printed electrode.

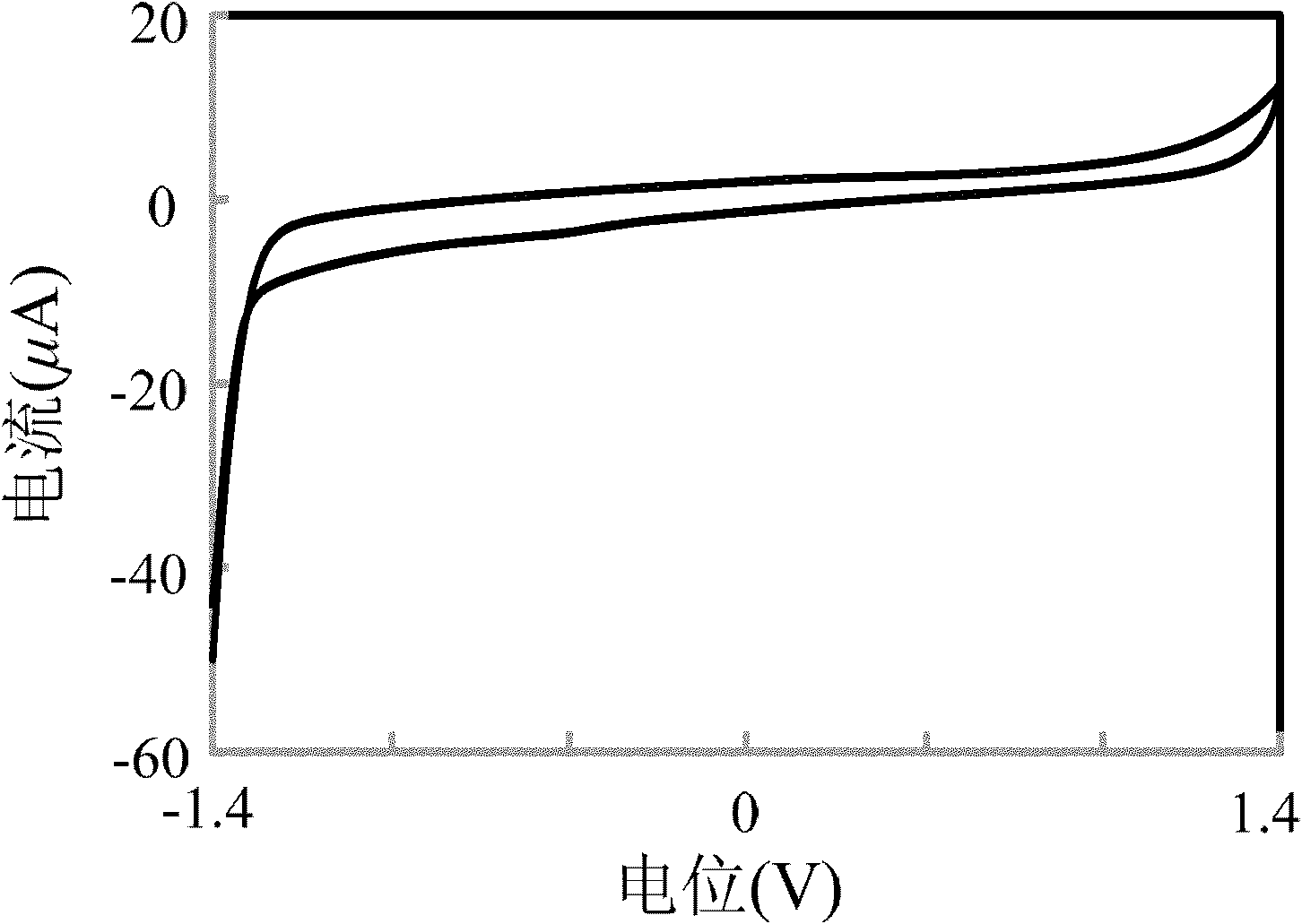

[0033] The prepared screen-printed electrode was placed in 0.1M phosphate buffer (pH 7.0), and the electrode was subjected to cyclic voltammetry scanning in the potential range from -1.4V to 1.4V, such as figure 2 , it can be seen that the background nois...

Embodiment 2

[0040] Take 1 mL of acetone and cyclohexanone and mix with each other, then add 0.02 g of cellulose acetate and stir until fully dissolved. Add 0.4 g of N-octylpyridine hexafluorophosphate and 0.6 g of graphite powder and stir until a homogeneous slurry is formed.

[0041] For electrode printing, first print the electrode leads on the polyvinyl chloride substrate, after drying the substrate, print the working electrode with the above-mentioned prepared paste, and place it in an oven after printing. Then place it at room temperature to cool. Finally, an insulating layer is printed to make a screen-printed electrode.

Embodiment 3

[0043] Take 2mL of acetone solution, then add 0.02g of cellulose acetate, and stir until fully dissolved. Add 0.2 g of N-octylpyridine hexafluorophosphate and 0.8 g of graphite powder and stir until a homogeneous slurry is formed.

[0044] Other same example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap