Process and device for eliminating lead-acid storage battery polar column adhesive bubbles

A technology of lead-acid batteries and poles, which is applied in the direction of electrical components, battery pack parts, circuits, etc., can solve the problems of low production efficiency, large heat generation, inconvenience, etc., and achieve the improvement of the process of eliminating air bubbles, and the device is easy to operate , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the features, technical means and achieved specific objectives and functions of the present invention, the present invention will be further described in detail below.

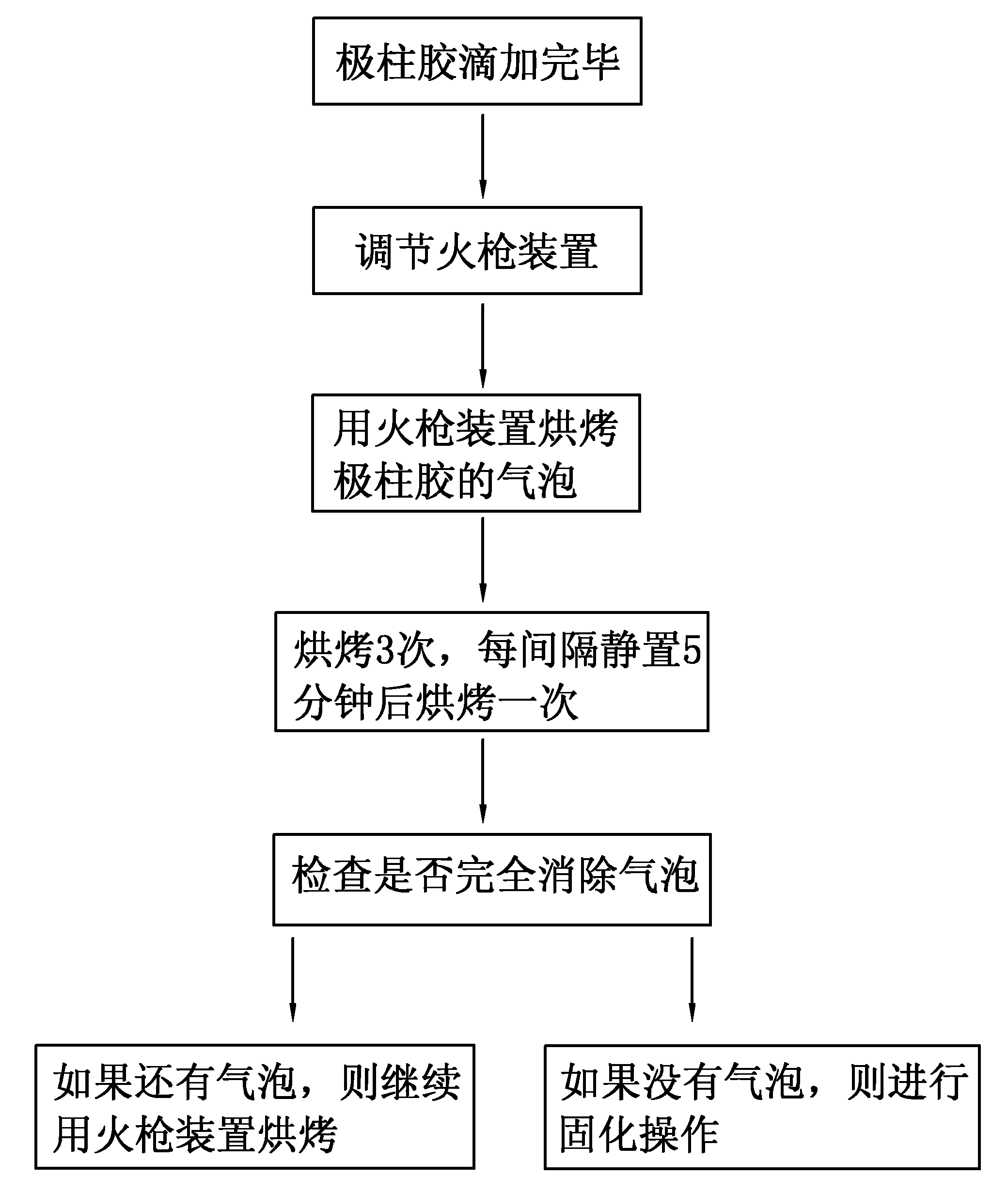

[0018] A process for eliminating air bubbles in lead-acid battery pole glue, the process steps are as follows:

[0019] Step 1: Carry out the glue dripping process for the pole of the lead-acid battery, and confirm that the glue has been added to the pole of the lead-acid battery and the amount of glue is moderate. This step is the process of dropping the pole glue in the production process of the VRLA battery. After the pole glue is added, due to the inherent characteristics of the pole glue, the main agent of the pole glue and the curing agent are mixed and stirred. Generates a lot of heat and creates bubbles. These bubbles not only affect the appearance of the battery, but also affect the quality of the battery. The traditional method is to use a fine needle to break ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com