Silicon mixed colloid electrolyte for lead acid storage batteries

A colloidal electrolyte and lead-acid battery technology, which is applied in lead-acid batteries, electric vehicles, vehicle energy storage, etc., can solve the problems of high price of fumed silica, high viscosity of colloidal electrolyte, and inability to fill batteries, etc., to achieve improvement Large discharge performance, deep discharge performance improvement, and the effect of avoiding hydration stratification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention relates to the mixing problem of two gelling agents in silica sol colloidal electrolytes. The essence is to complement the advantages and disadvantages of different gelling agent colloidal electrolytes, so as to reduce the raw material cost of colloidal electrolytes and ensure uniform, stable and non-hydrating electrolytes. Layering, the purpose of increasing the capacity of the gel battery, improving the performance of the large discharge, and prolonging the cycle life.

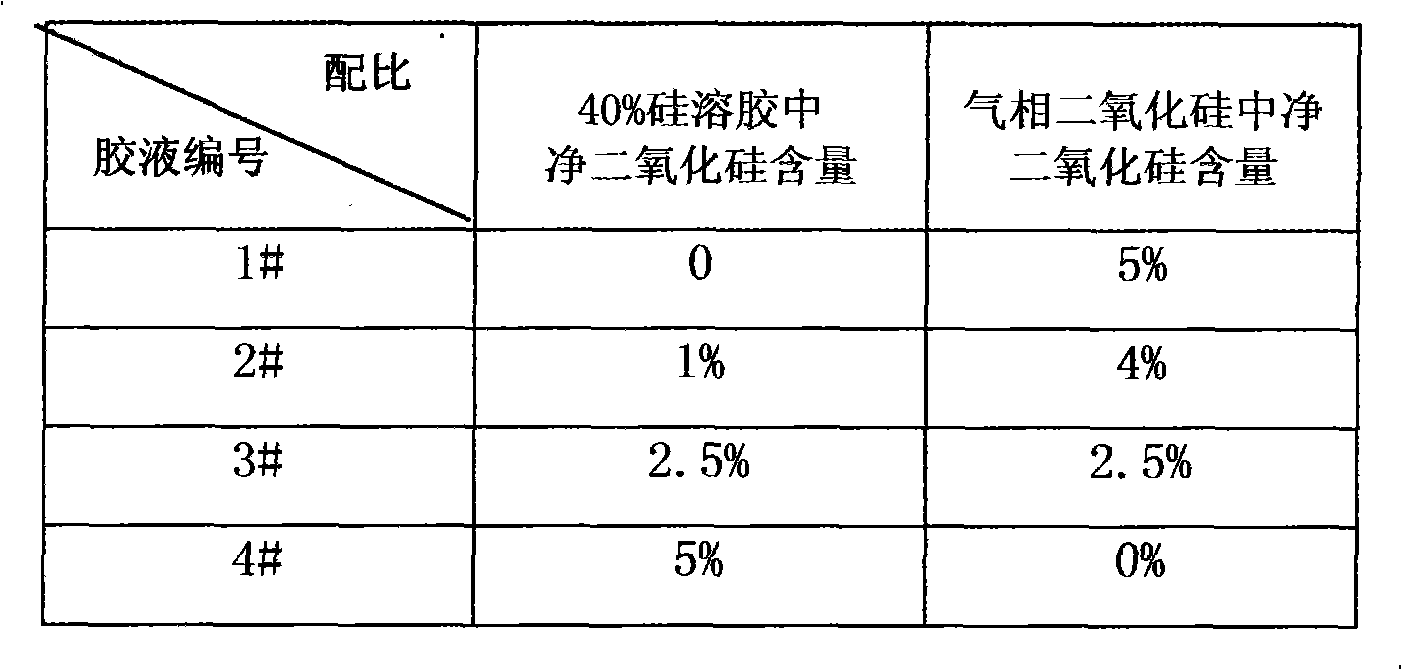

[0019] A kind of silicon-miscible colloidal electrolytic solution used in lead-acid storage battery according to the present invention comprises: 89~93.5% density is the sulfuric acid solution of 1.26~1.32g / ml, the concentration of 2.5~10% It is 40% silica sol, 1-4% fumed silica, and the total silica content in the electrolyte is 5%. Wherein, the optimal value of density of sulfuric acid solution is 1.28g / ml, and sulfuric acid solution is the mixture of sulfuric acid and water. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com