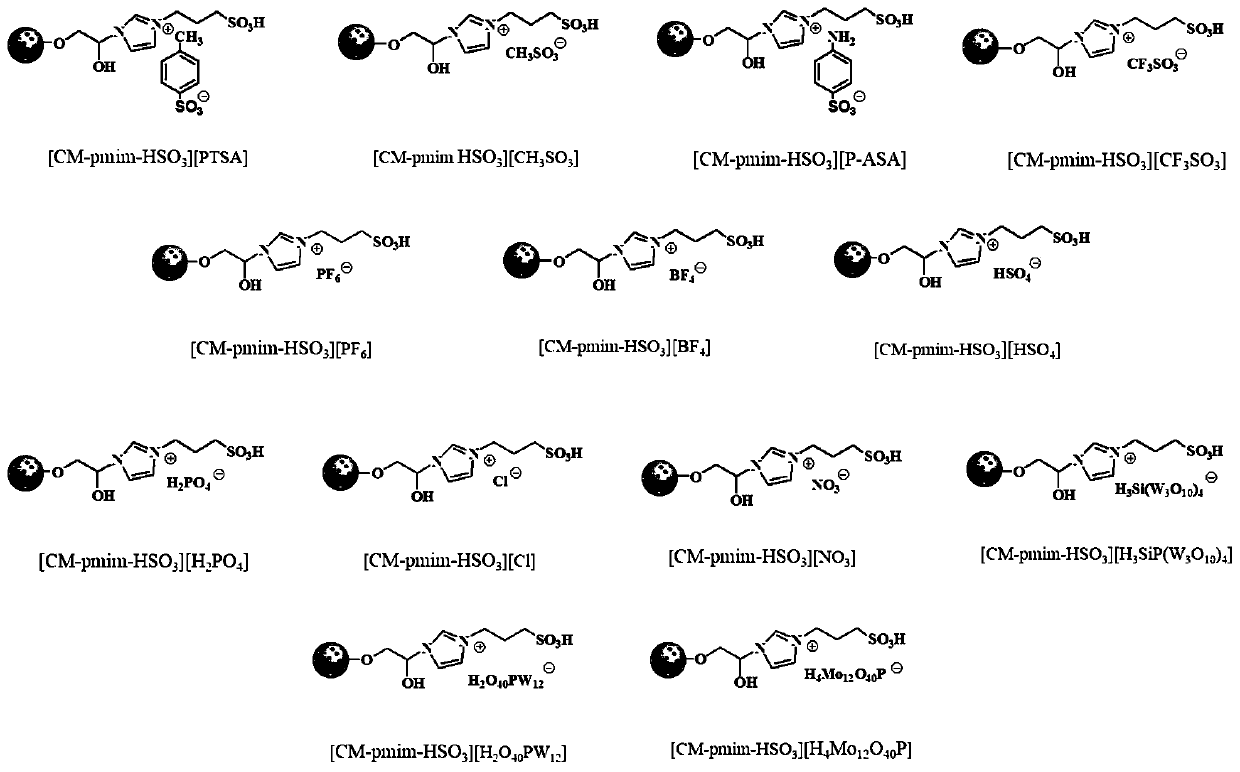

Sulfonated cellulose-based ionic liquid catalysts and preparation method thereof

A liquid catalyst and cellulose technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., to achieve mild reaction conditions, which are conducive to large-scale production and preparation processes simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

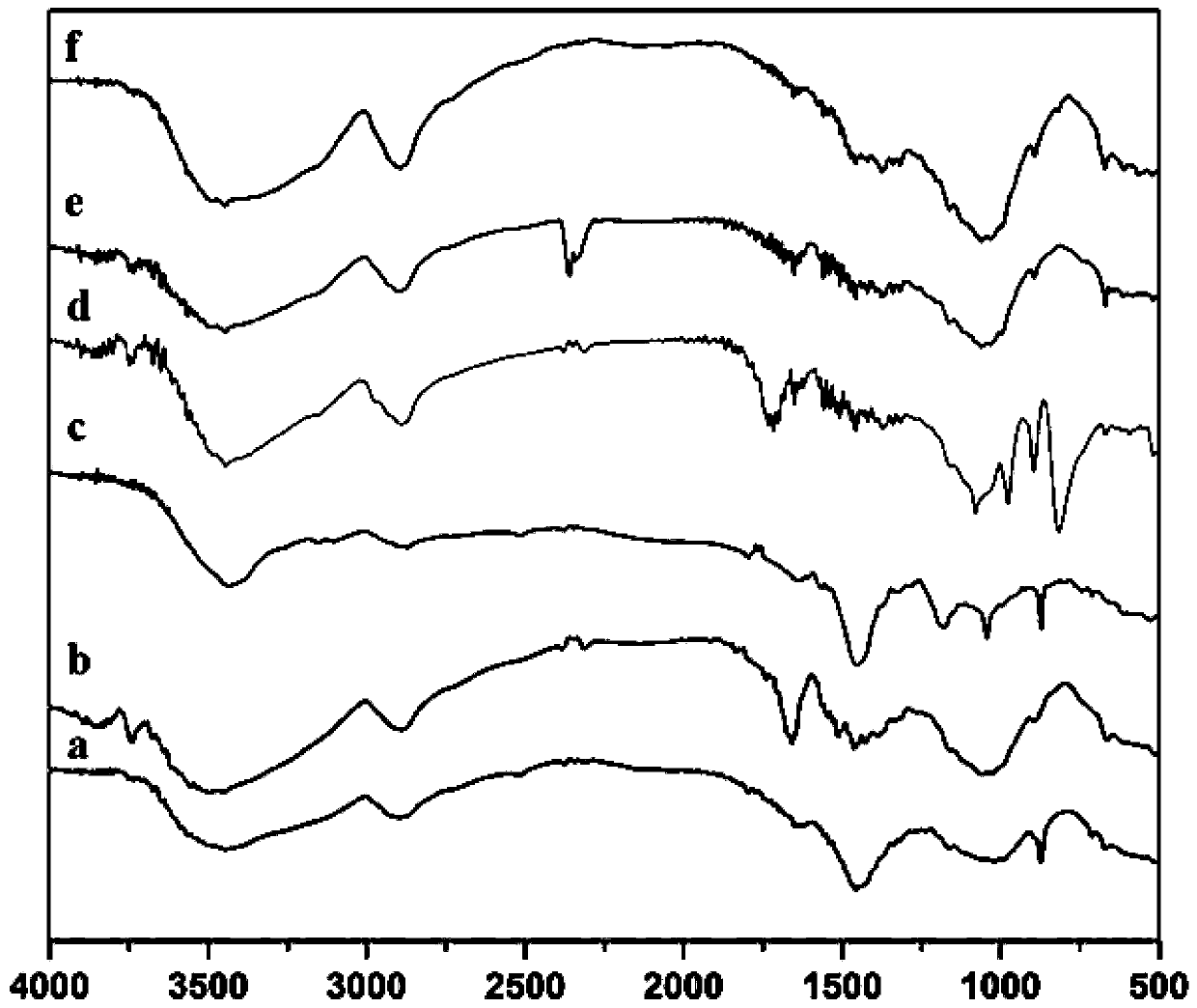

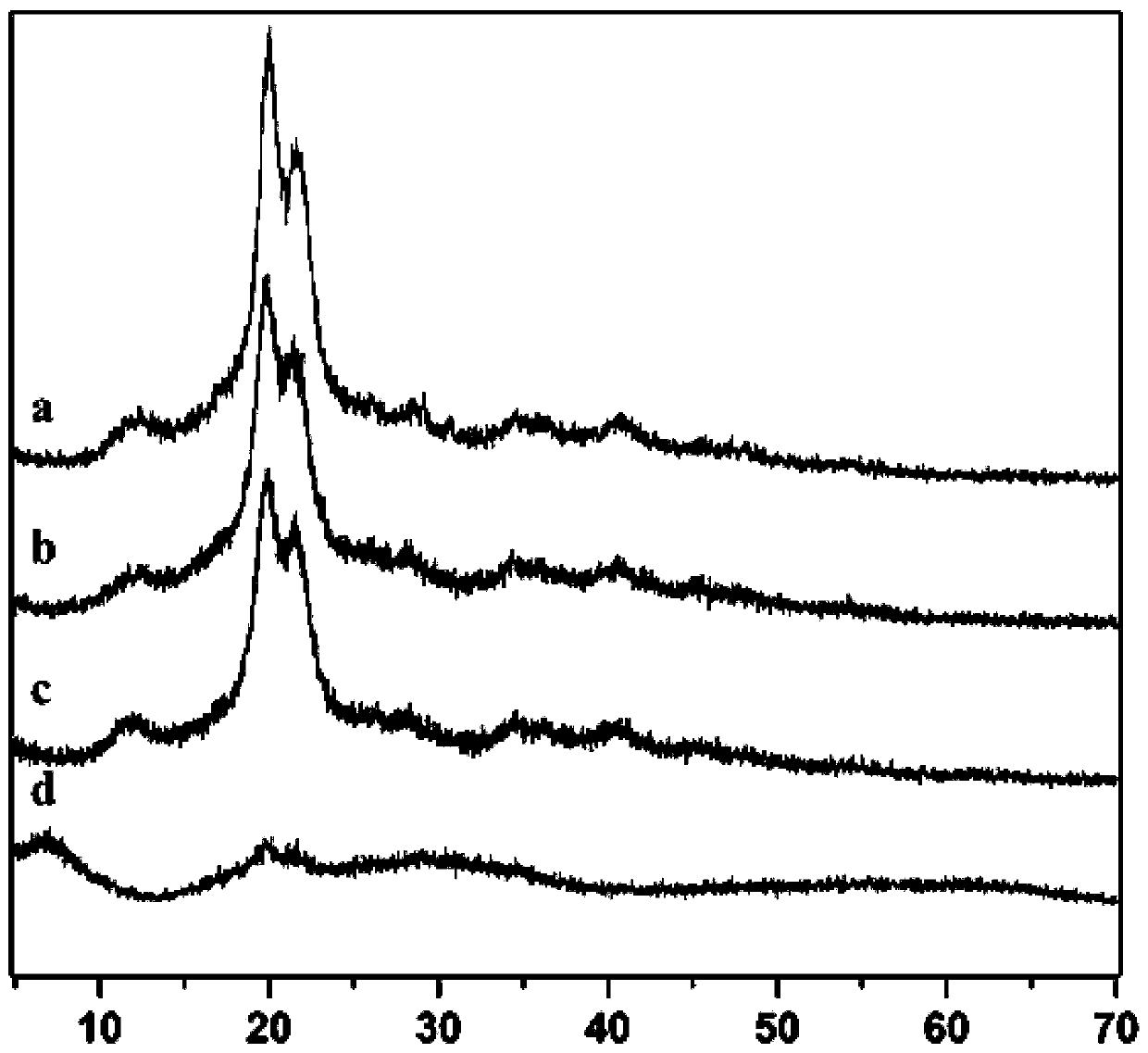

Method used

Image

Examples

Embodiment 1

[0027] [PCM-pmim-HSO 3] Preparation of [P-TSA]: put dry 5g porous cellulose microspheres into 5mL epichlorohydrin and 10mL 3mol / L sodium hydroxide solution, shake the table at 25°C, react for 8h, and the microspheres Repeated washing and suction filtration until the pH of the filtrate is neutral, disperse 5g of microspheres and 5g of imidazole in DMF solvent in an oil bath at 80°C, react for 8h, add to toluene containing 1,3-propane sultone after repeated washing and suction filtration Oil bath in the solution at 50°C, react for 5h, wash and filter to obtain sulfonated cellulose-based ionic liquid intermediate [PCM-pmim-HSO 3 ]; Weigh 1g of sulfonated cellulose-based ionic liquid intermediate [PCM-pmim-HSO 3 ], dispersed in 3mL water, added dropwise 1mL 0.01mol / mL p-toluenesulfonic acid aqueous solution, slowly warmed up to 90°C, and reacted for 5h to obtain [PCM-pmim-HSO 3 ][P-TSA].

Embodiment 2

[0029] [PCM-pmim-HSO 3 ][CH 3 SO 3 ] preparation: put dry 5g porous cellulose microspheres into 6mL epichlorohydrin and 15mL 3mol / L sodium hydroxide solution, shake the table at 25°C, react for 5h, and wash the microspheres repeatedly to The pH of the filtrate is neutral, disperse 5g microspheres and 3g imidazole in DMF solvent, oil bath 70°C, react for 6h, wash and filter repeatedly, add to toluene solution containing 1,3-propane sultone, oil bath 50°C , reacted for 4h, and obtained the sulfonated cellulose-based ionic liquid intermediate [PCM-pmim-HSO 3 ]; Weigh 1g of sulfonated cellulose-based ionic liquid intermediate [PCM-pmim-HSO 3 ], dispersed in 5mL water, added dropwise 1mL 0.01mol / mL methanesulfonic acid aqueous solution, slowly raised to 90°C, and reacted for 5h to obtain [PCM-pmim-HSO 3 ][CH 3 SO 3 ].

Embodiment 3

[0031] [PCM-pmim-HSO 3 ][HSO 4 ] preparation: put dry 5g porous cellulose microspheres into 8mL epichlorohydrin and 16mL 3mol / L sodium hydroxide solution, shake the table at 25°C, react for 7h, and wash and suction filter the microspheres repeatedly until the end of the reaction. The pH of the filtrate is neutral, disperse 5g of microspheres and 10g of imidazole in DMF solvent, oil bath 75°C, react for 7h, wash and filter repeatedly, add to toluene solution containing 1,3-propane sultone, oil bath 40°C , reacted for 5h, washed and filtered to obtain the sulfonated cellulose-based ionic liquid intermediate [PCM-pmim-HSO 3 ]; Weigh 1 g of sulfonated cellulose-based ionic liquid cation [PCM-pmim-HSO 3 ], dispersed in 4mL aqueous solution, added dropwise 0.25mL sulfuric acid, slowly warmed up to 50°C, and reacted for 5h to obtain [PCM-pmim-HSO 3 ][HSO 4 ].

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com