A kind of preparation method of lead-acid storage battery colloidal electrolyte

A colloidal electrolyte, lead-acid battery technology, applied in lead-acid batteries and other directions, can solve the problems of short gelation time, poor gel stability, poor gel strength, etc., to avoid hydration stratification, and to achieve good thixotropy , the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

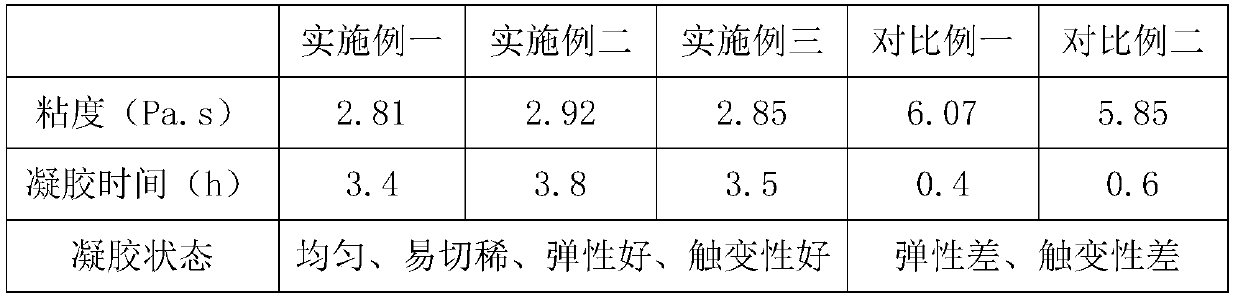

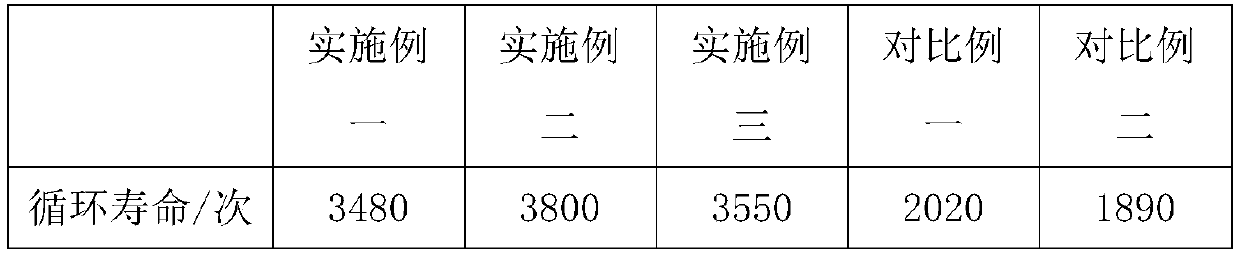

Embodiment 1

[0018] A kind of preparation method of lead-acid storage battery colloidal electrolyte that the present invention proposes comprises the following steps:

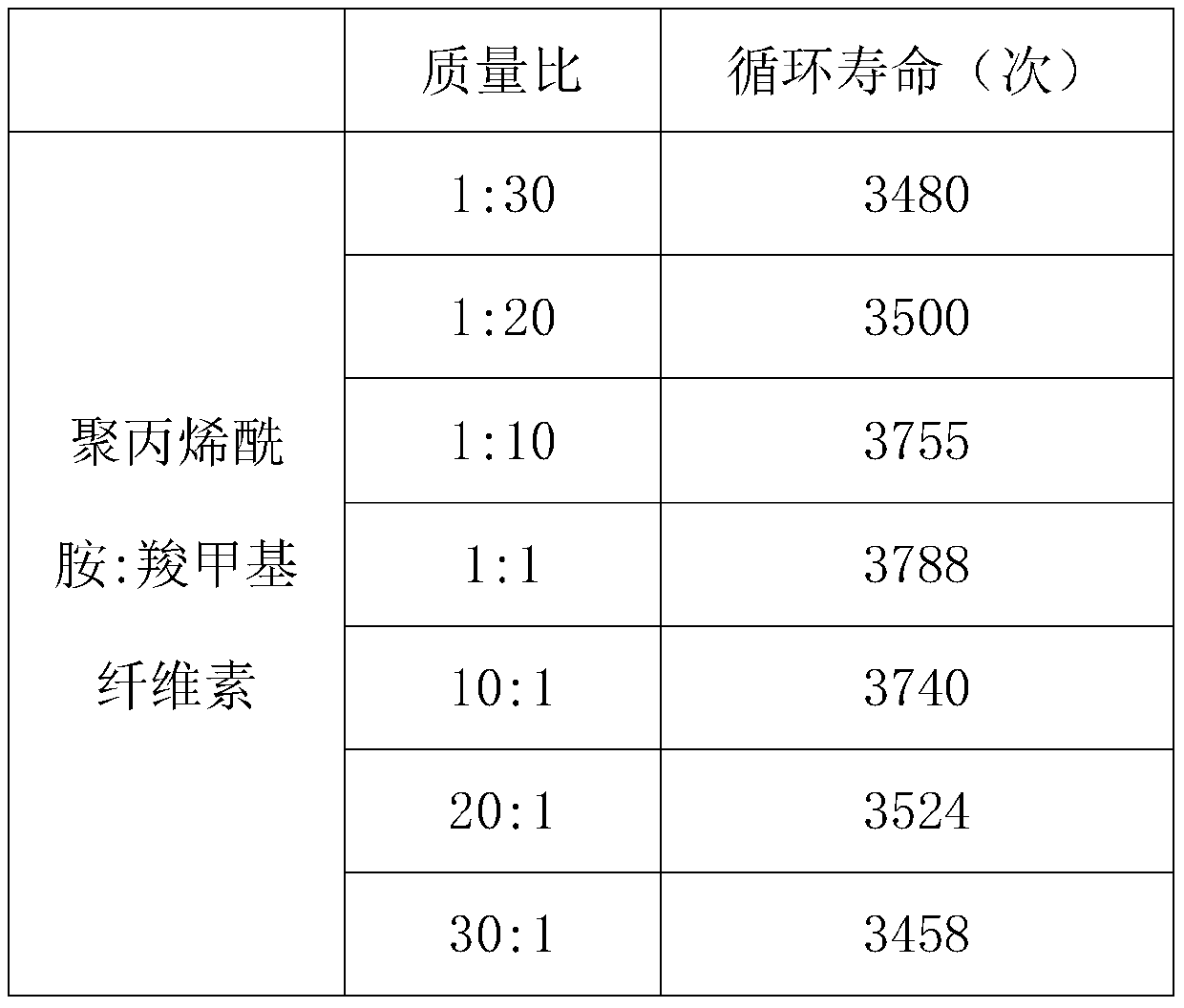

[0019] S1. Prepare the raw materials for the preparation of lead-acid battery colloidal electrolyte, including 8% nano silicon dioxide, 0.06% methyltrimethoxysilane, 3% dimethicone, 0.9% sulfate, nano Boron oxide 0.5%, 1-allyl-3-methylimidazolium chloride 0.7%, grease 0.15%, fatty alcohol polyoxyethylene ether sodium sulfate 0.5%, stabilizer 0.3%, sulfuric acid 44%, the rest is distilled water , where the density of sulfuric acid solution is 1.56g / cm 3 , sulfate is the composite agent of lead sulfate, cobalt sulfate, sodium sulfate, tin sulfate and aluminum sulfate that mass ratio is 1.8:1.2:3:0.7:2.5; Stabilizer is polyacrylamide and polyacrylamide that mass ratio is 1:30 Compositions of carboxymethylcellulose;

[0020] S2. Add nano-silica to the ultrasonic disperser, add distilled water until the mass fraction of nano-s...

Embodiment 2

[0025] A kind of preparation method of lead-acid storage battery colloidal electrolyte that the present invention proposes comprises the following steps:

[0026] S1. Raw materials for preparation of colloidal electrolyte for lead-acid battery, including 6% nano silicon dioxide, 0.04% methyltrimethoxysilane, 2% dimethyl polysiloxane, 0.7% sulfate, nano Boron oxide 0.35%, 1-allyl-3-methylimidazolium chloride 0.5%, grease 0.12%, fatty alcohol polyoxyethylene ether sodium sulfate 0.3%, stabilizer 0.2%, sulfuric acid 40%, the rest is distilled water , where the density of sulfuric acid solution is 1.52g / cm 3 , sulfate is the composite agent of lead sulfate, cobalt sulfate, sodium sulfate, tin sulfate and aluminum sulfate that mass ratio is 1.4:0.8:2.5:0.5:2; Stabilizer is polyacrylamide and polyacrylamide that mass ratio is 1:1 Compositions of carboxymethylcellulose;

[0027] S2. Add nano-silica to the ultrasonic disperser, add distilled water until the mass fraction of nano-sil...

Embodiment 3

[0032]A kind of preparation method of lead-acid storage battery colloidal electrolyte that the present invention proposes comprises the following steps:

[0033] S1. Raw materials for preparation of colloidal electrolyte for lead-acid battery, including 3% nano silicon dioxide, 0.02% methyltrimethoxysilane, 1% dimethyl polysiloxane, 0.5% sulfate, nano Boron oxide 0.2%, 1-allyl-3-methylimidazolium chloride 0.3%, grease 0.08%, fatty alcohol polyoxyethylene ether sodium sulfate 0.1%, stabilizer 0.1%, sulfuric acid 35%, the rest is distilled water , where the density of sulfuric acid solution is 1.48g / cm 3 , sulfate is the composite agent of lead sulfate, cobalt sulfate, sodium sulfate, tin sulfate and aluminum sulfate that mass ratio is 1:0.5:2:0.3:1.5; Stabilizer is polyacrylamide and polyacrylamide that mass ratio is 30:1 Compositions of carboxymethylcellulose;

[0034] S2. Add nano-silica to the ultrasonic disperser, add distilled water until the mass fraction of nano-silica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com