Deicing and inspection robot for high voltage line

A technology for inspection robots and high-voltage lines, which is applied to manipulators, overhead lines/cable equipment, electrical components, etc., and can solve the problems of high risk, high labor intensity, and difficulty in inspections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

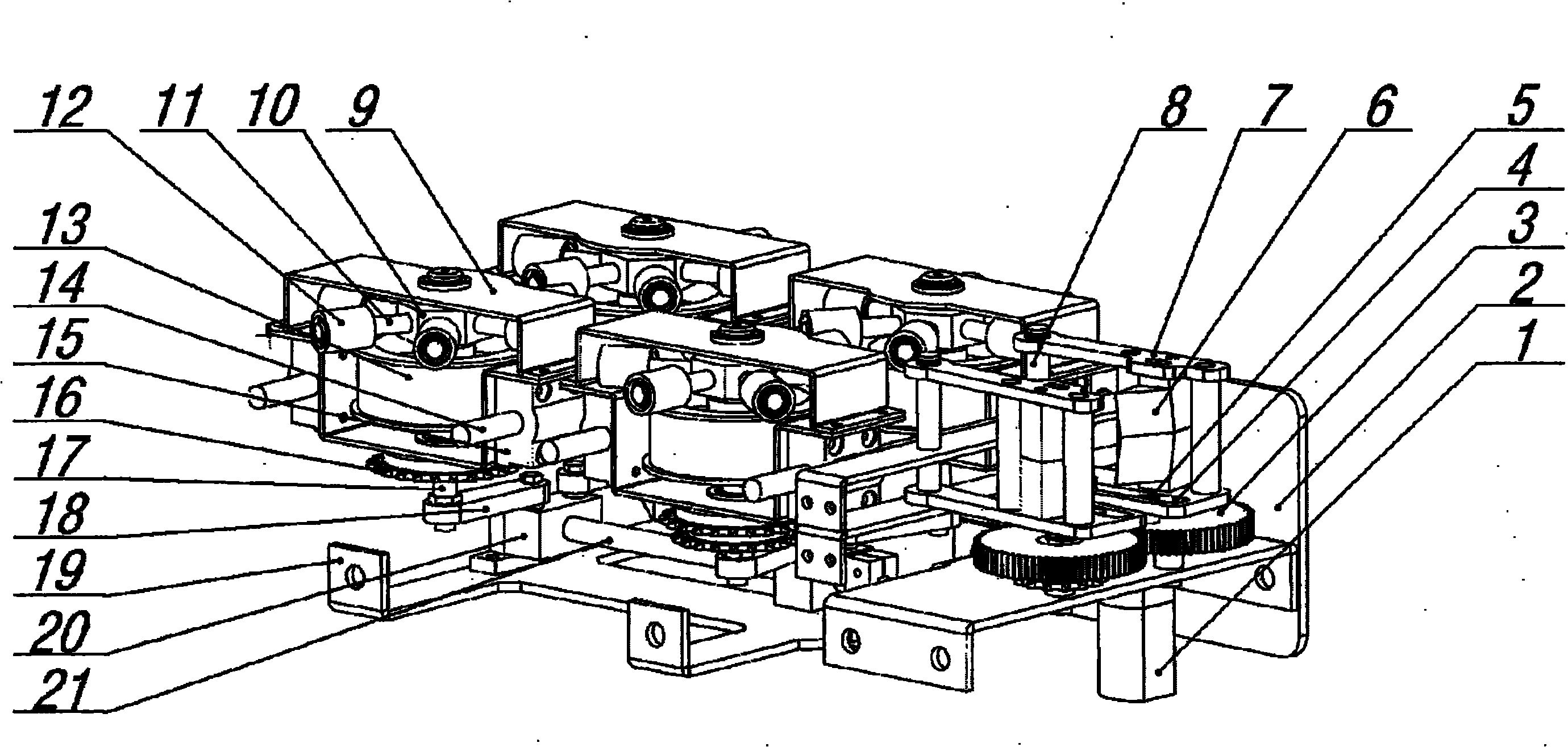

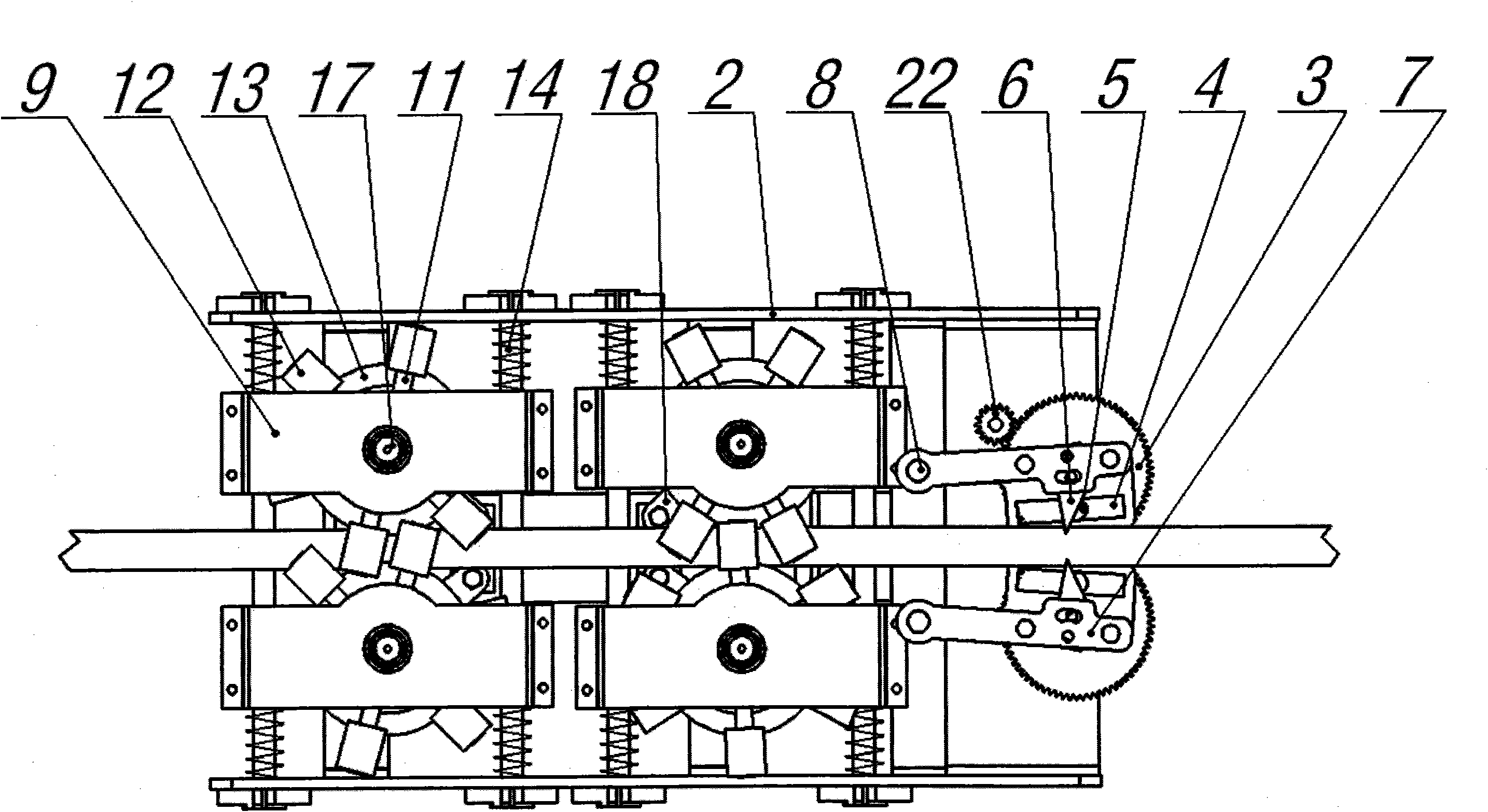

[0025] In order to realize the purpose of the present invention, it is necessary to complete the following functions and motions: (1) the body is suspended on the wire mechanism, requiring stable and reliable multi-point positioning; The mechanism ensures that the fuselage is symmetrical about the wires; (3) the reciprocating cutting motion of the deicing knife requires continuous and stable motion, fast speed, and a certain acceleration when occluding; (4) the forward walking motion of the robot follows the deicing progress of the fuselage Keep moving forward, remove the next section of ice, and the speed is stable; (5) Can smoothly climb over or pass through obstacles on the high-voltage line of obstacles, including counterweights, hanging fittings, etc.

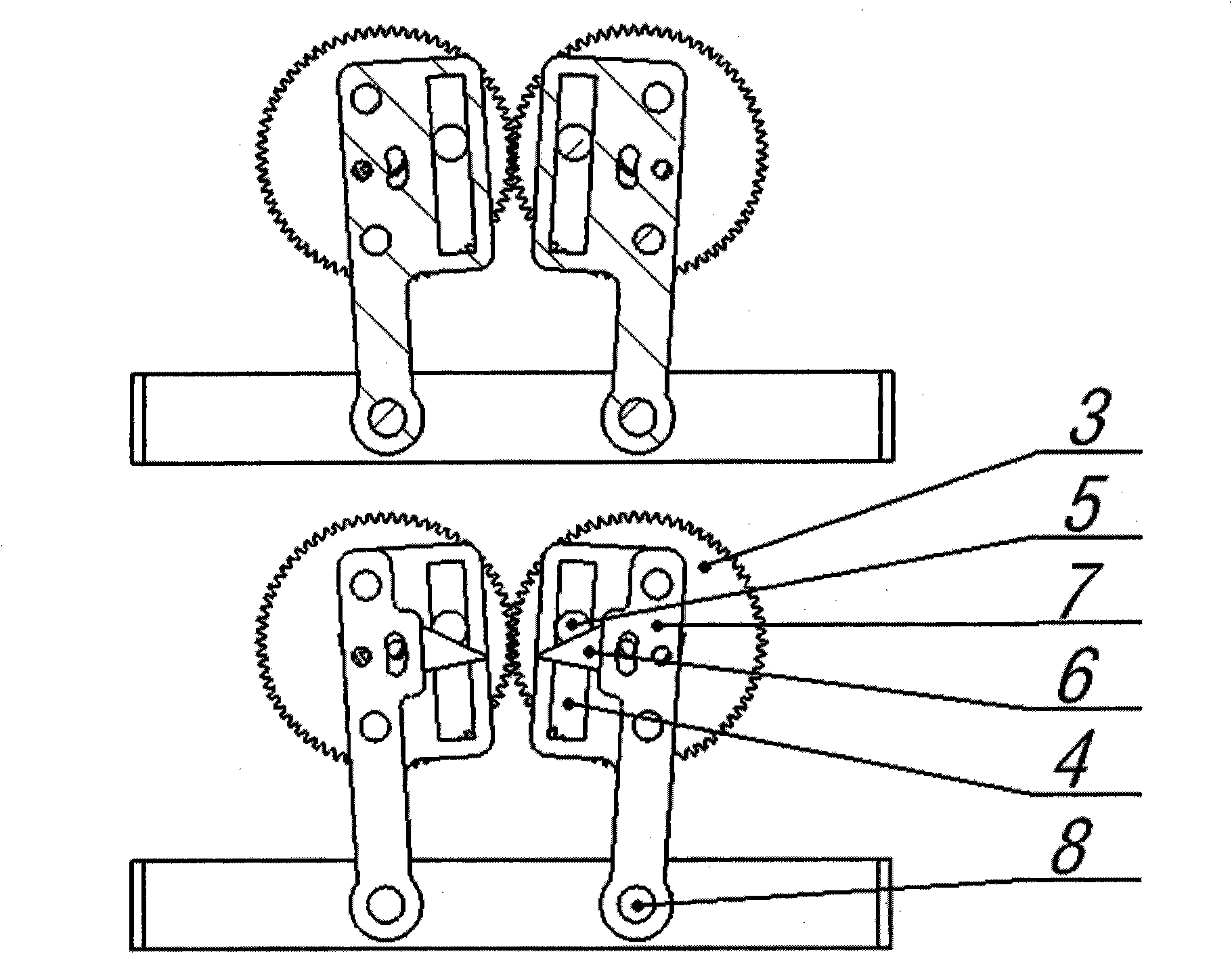

[0026] Above-mentioned deicing knife 6 is driven by an eccentric crank slider mechanism, as image 3 , Through the eccentric slider, the periodic rotary motion is changed into a reciprocating swing at a certain angle. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com