Water-reactive Al composite material, water-reactive Al film, process for production of the Al film, and constituent member for film depostion chamber

A composite material and manufacturing method technology, applied in metal material coating process, ion implantation plating, gaseous chemical plating and other directions, to achieve the effects of easy cost, easy recovery, and increased reuse times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

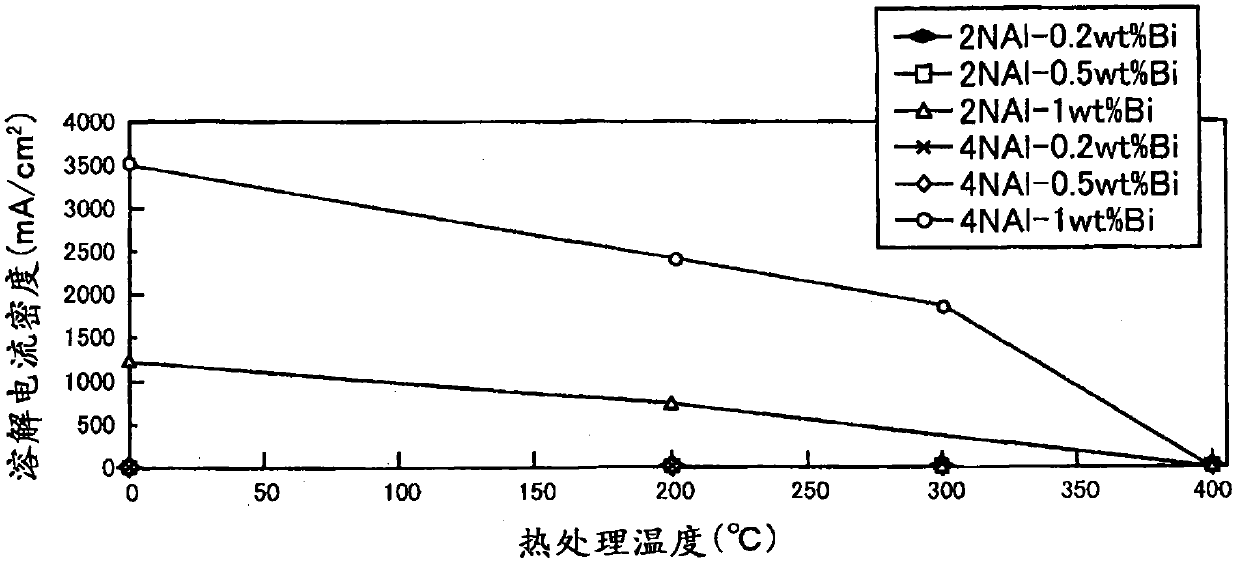

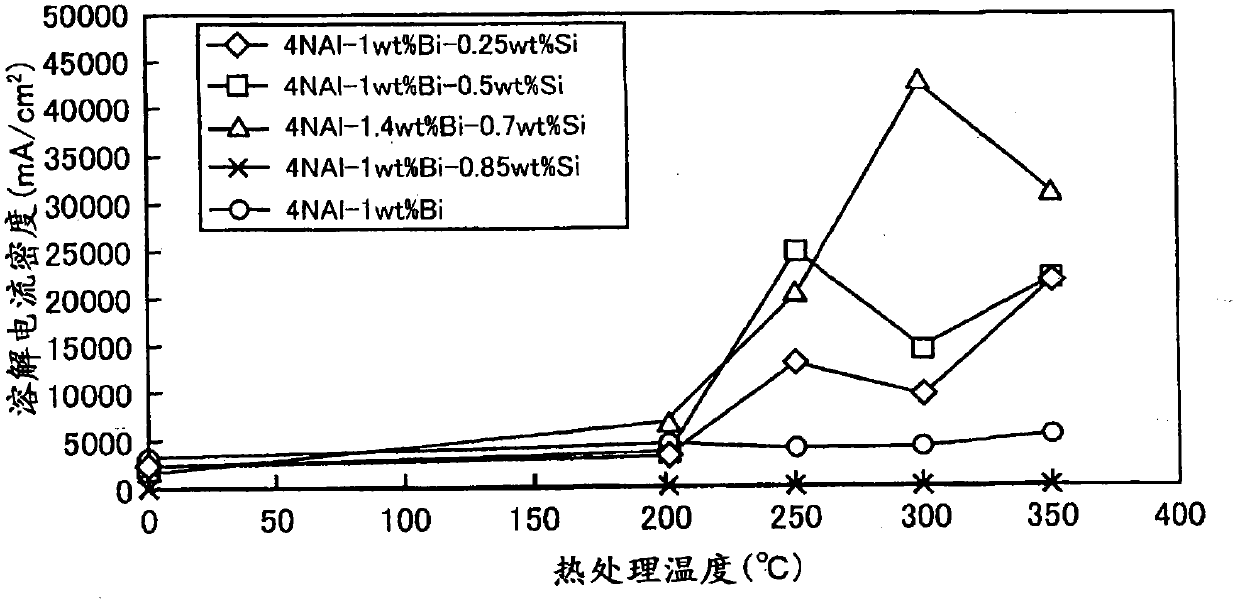

[0060] Based on the results of Comparative Example 1, 4NAl was used to study the amount of Bi added, the amount of Si added, and the dissolution of the resulting thermally sprayed coating in the Al-Bi-Si composition to which Bi and Si (the total amount of impurity Si) were added. sexual relationship. The amounts of Bi and Si added are based on Al weight.

[0061] 4NAl-1wt%Bi (impurity Si: 90ppm)

[0062] 4NAl-1wt%Bi-0.25wt%Si (impurity Si: 90pm)

[0063] 4NAl-1wt%Bi-0.5wt%Si (impurity Si: 100ppm)

[0064] 4NAl-1.4wt%Bi-0.7wt%Si (impurity Si: 100ppm)

[0065] 4NAl-1wt%Bi-0.85wt%Si (impurity Si: 100ppm)

[0066] Using a thermal spraying material that mixes Al, Bi, and Si in the above-mentioned proportions, dissolves Bi and Si uniformly in Al, and processes it into a rod shape, it is sprayed by molten rod flame spraying (heat source: C 2 h 2 -O 2 gas, about 3000°C), in the air atmosphere, spray on the surface of the aluminum substrate to form a sprayed coating. Each of th...

Embodiment 2

[0071] Using a sputtering device provided with an anti-adhesion plate coated with the 4NAl-1wt% Bi-0.5wt% Si sprayed film (film thickness 200 μm) obtained in Example 1, after implementing platinum (Pt) film formation for 30 cycles, The anti-adhesion plate to which the Pt was attached was removed and treated with warm water at 80°C. As a result, the sprayed coating was dissolved in 20 minutes, as shown in image 3 As shown in , the adhered film of Pt was peeled off from the antiadhesive plate. Therefore, Pt as a film-forming material can be easily recovered. At this time, AlOOH was precipitated in warm water.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap