Full-automatic plaiting device for casting machine

A fully automatic, pouring machine technology, applied in applications, cheese substitutes, dairy products, etc., can solve problems such as heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with accompanying drawing, the utility model will be further described:

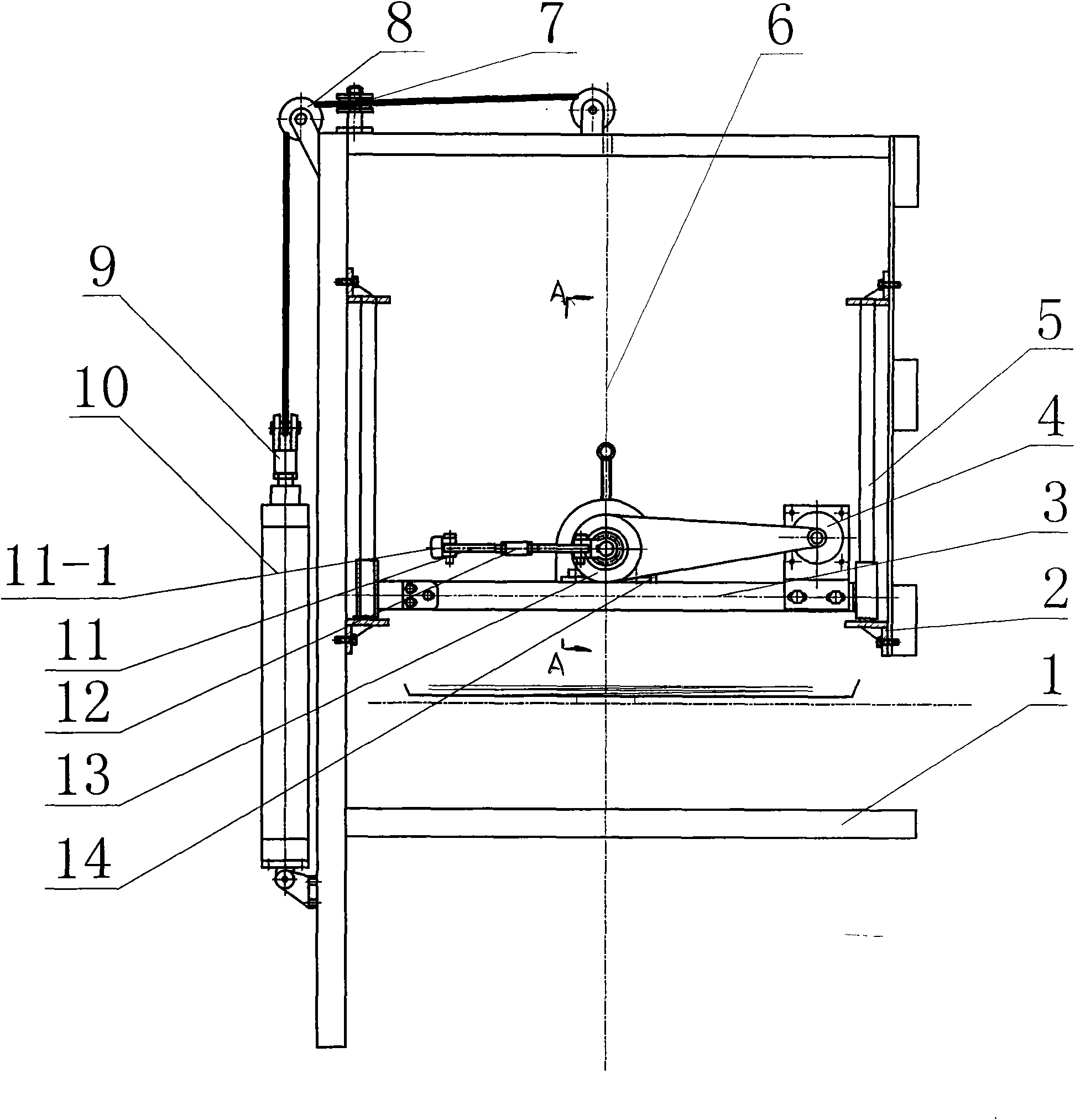

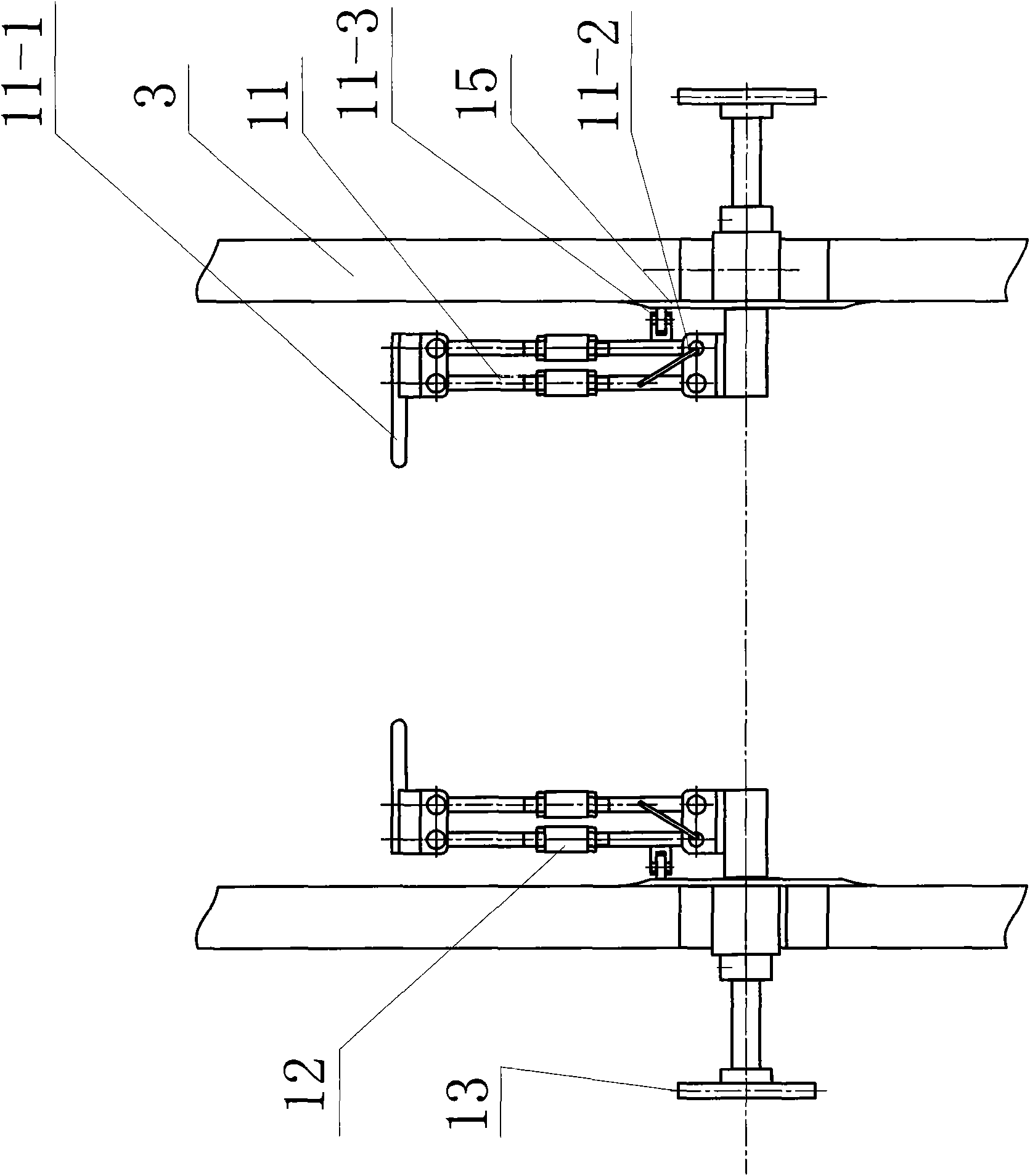

[0008] See attached figure 1 , 2 , the whole machine is installed on the frame (1), the upper and lower sides of the frame (1) are fixed with fixing seats (2), and guide posts (5) are installed between the two fixing seats (2). The guide sleeve (3-1) on the cross bar (3) is flexibly connected with the guide post (5) between the posts (5), and the step motor (4) is fixed on the cross bar (3), and the step motor (4 ) is connected with the synchronous wheel (13) that is located in the synchronous wheel seat (14) by the synchronous belt, the regulator (12) that is fixed with manipulator (11) flexibly on the extension shaft of synchronous wheel (13), two regulators ( The top of 12) is provided with movable movable arm (11-1) on the manipulator (11), between the two regulators (12) inside the front and rear two manipulators (11) and the extension shaft of the synchronous wheel (13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com