Unidirectional chain type extendable gangway ladder

A telescopic ladder and gangway technology, which is applied to ships, cargo handling equipment, passenger handling equipment, etc., can solve the problems of complex overall structure, inconvenient use, and high cost, and achieve the effects of simple operation, reliable structure, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

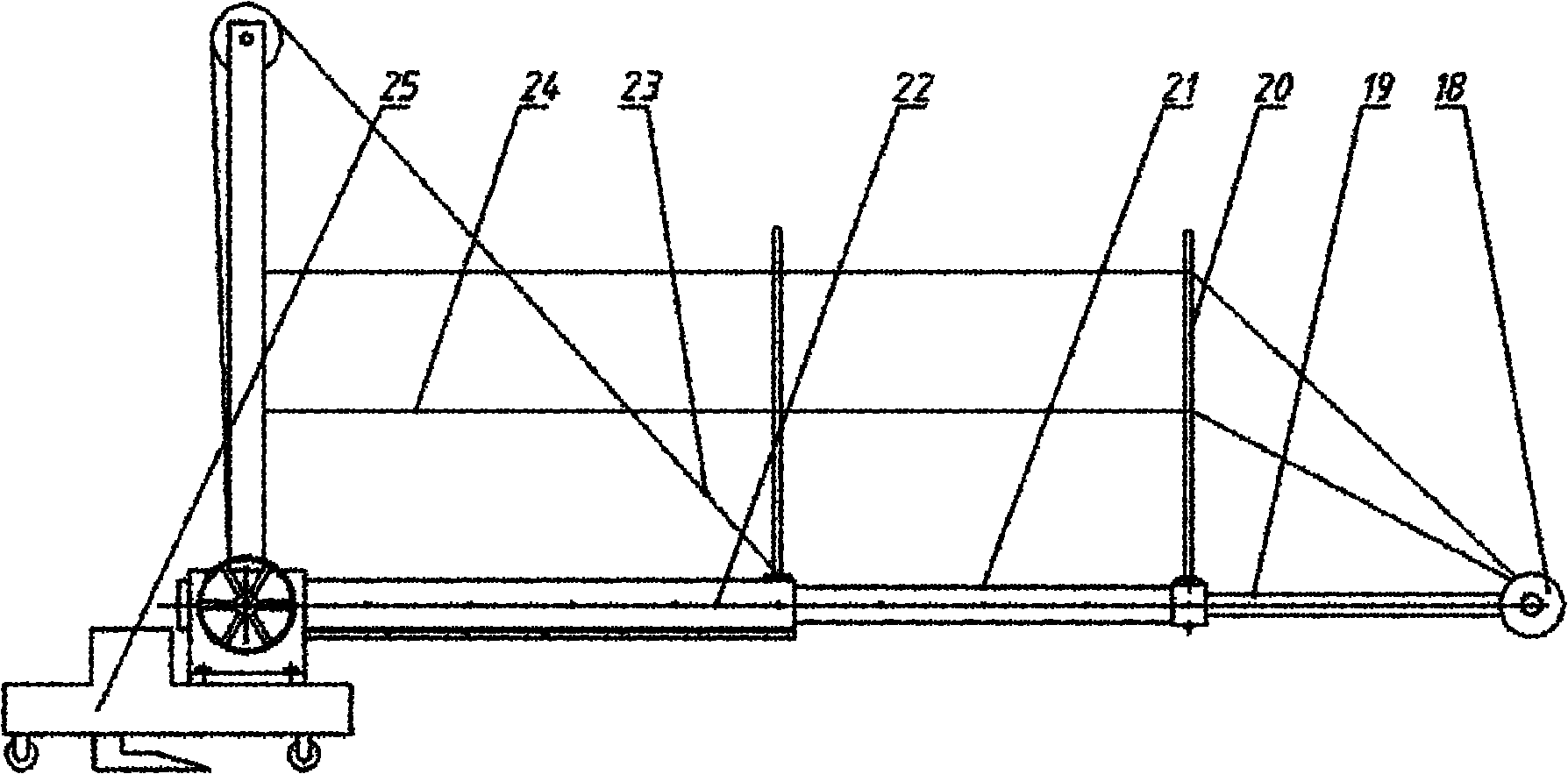

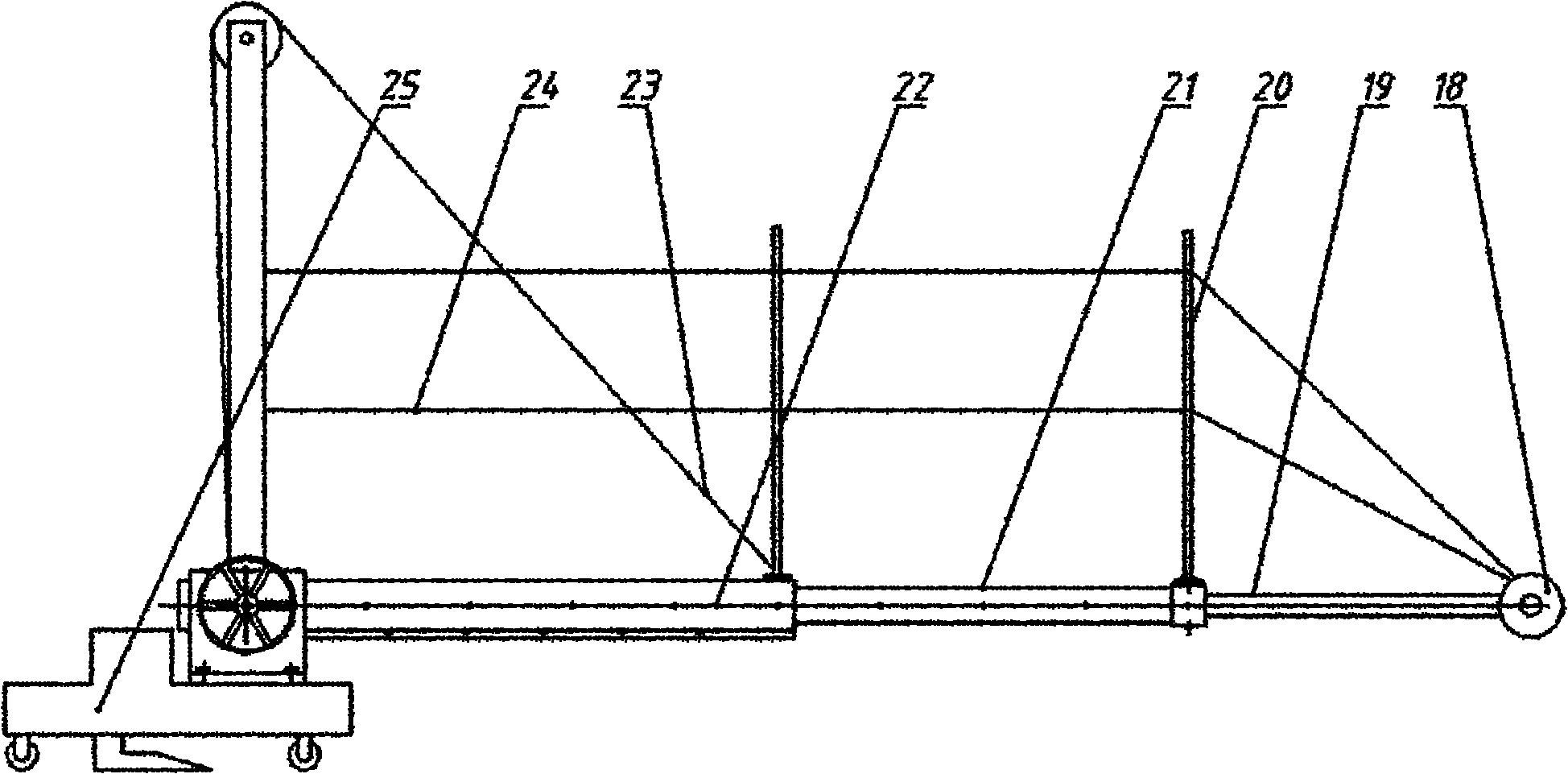

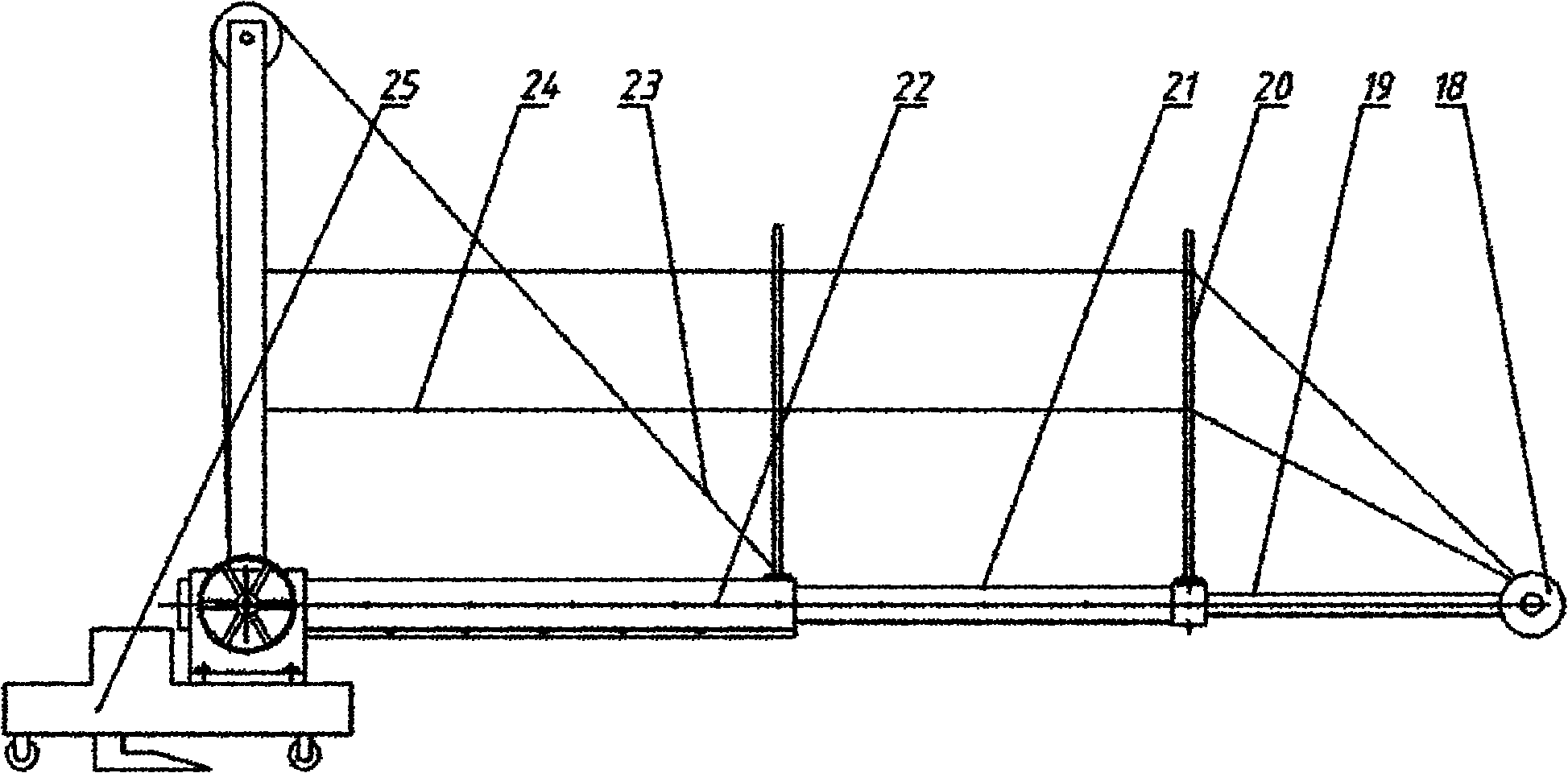

[0020] combine figure 1 and figure 2 , the one-way chain telescopic gangway of the present invention comprises: motor and speed reducer 1, electromagnetic bolt 2, guide groove 3, gangway seat 4, drive handle 5, rotating shaft 6, sprocket wheel 7, one-way chain 8, clutch internal gear Component 9, rope winding wheel 10, clutch outer gear part 11, chute 12, stop block 13, inner limit block 14, chain holder 15, outer limit block 16, one-way chain fixing seat 17, adapting wheel 18, The second telescopic ladder 19, column 20, first telescopic ladder 21, fixed ladder 22, steel wire rope 23, guardrail sling 24 and integral drag frame device 25. It is a three-section one-way chain telescopic gangway. It includes five parts: the main body of the retractable gangway, the telescopic mechanism of the gangway, the pitching mechanism of the gangway, the overall drag frame d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com