Media stocker, paper feeding device, and method of controlling posture of recording media

A technology of recording medium and paper feeding device, which can be used in transportation and packaging, thin material handling, and separation of objects, etc., and can solve problems such as poor transportation and poor state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

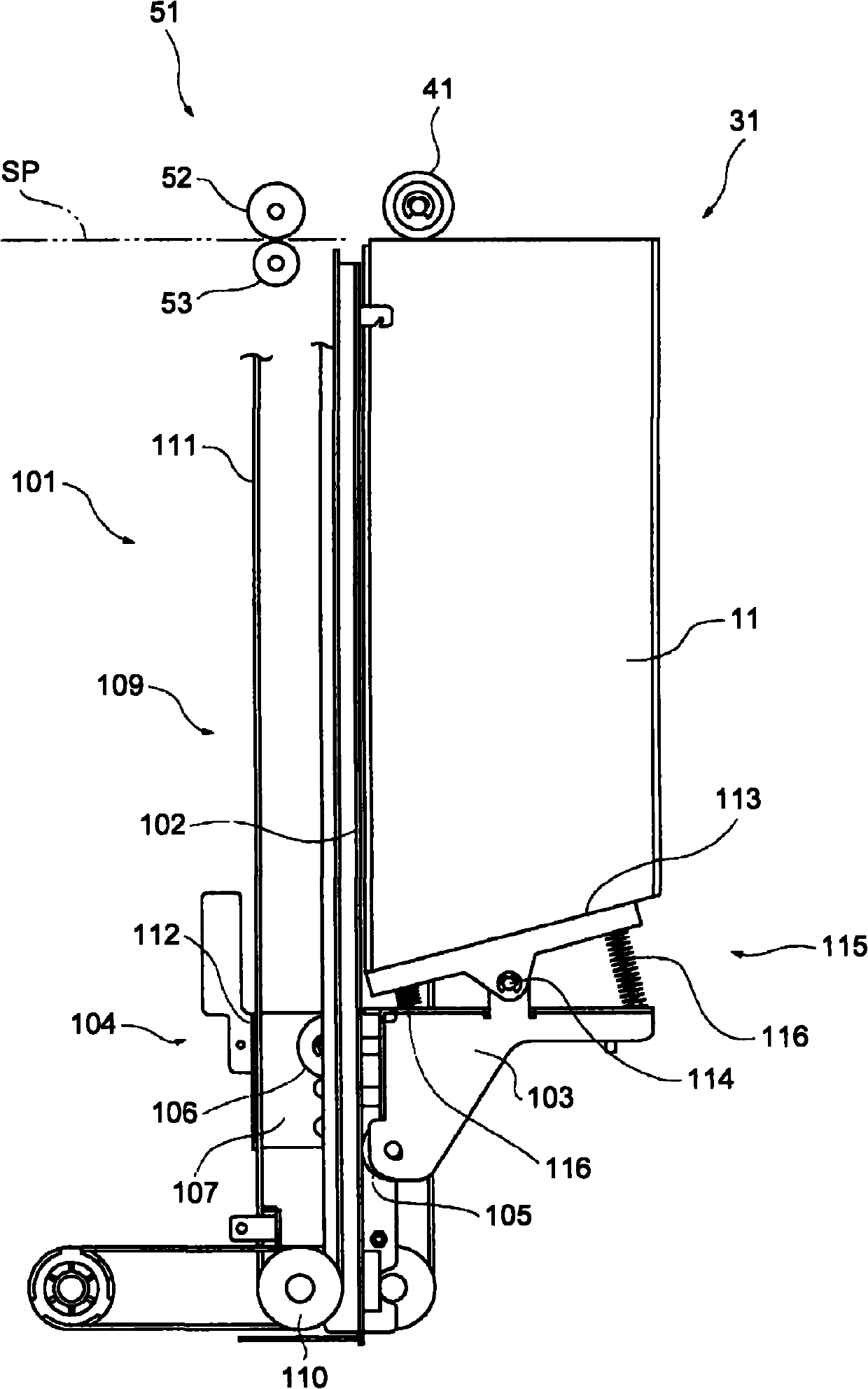

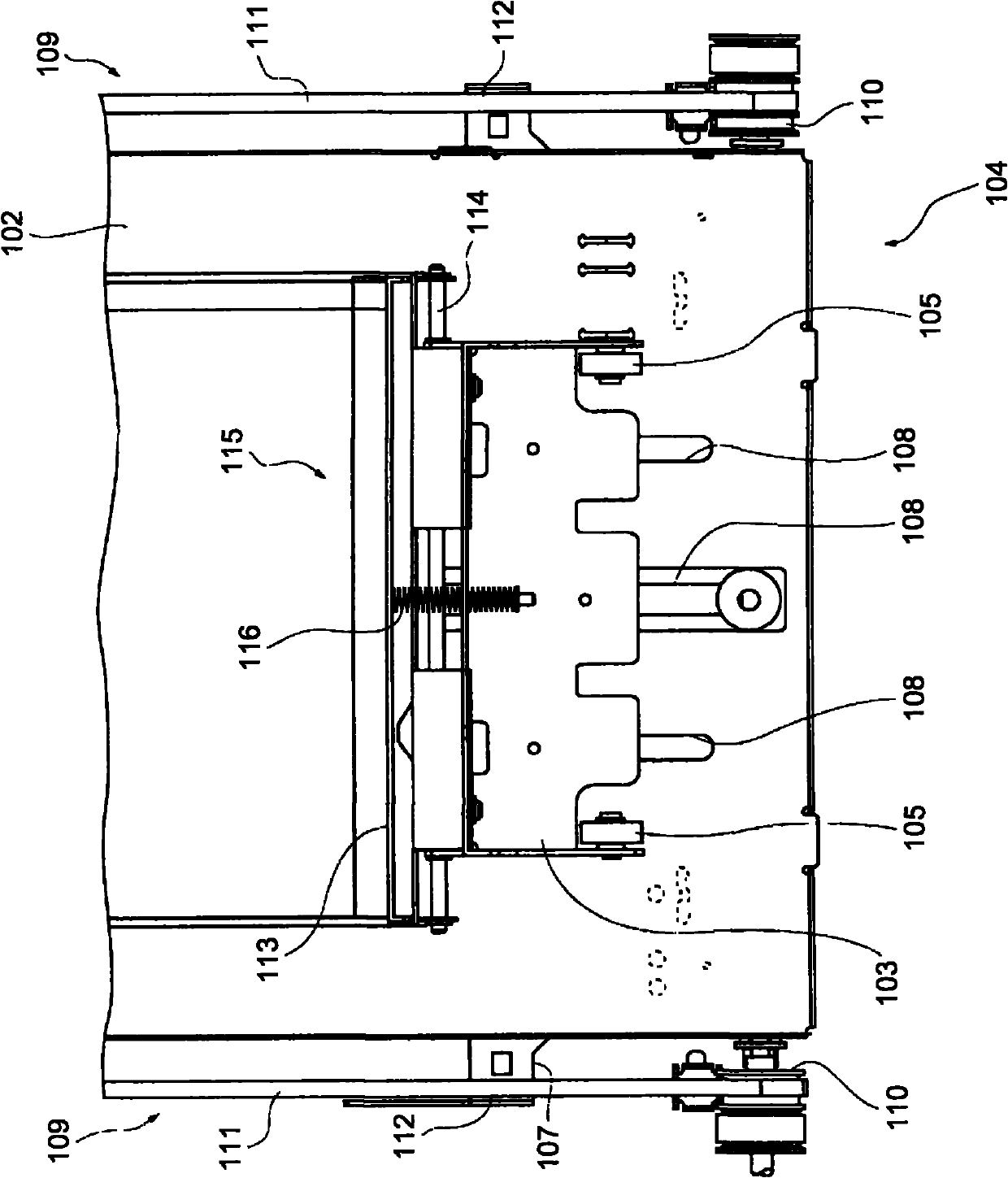

[0021] figure 1 is the overall front view. The paper feeding device 31 of the present embodiment is provided with a pickup roller 41 and a separation mechanism 51 corresponding to the medium stocker 101 . As an example, the paper supply device 31 will figure 2 The recording media 11 shown are stored in a media stocker 101 .

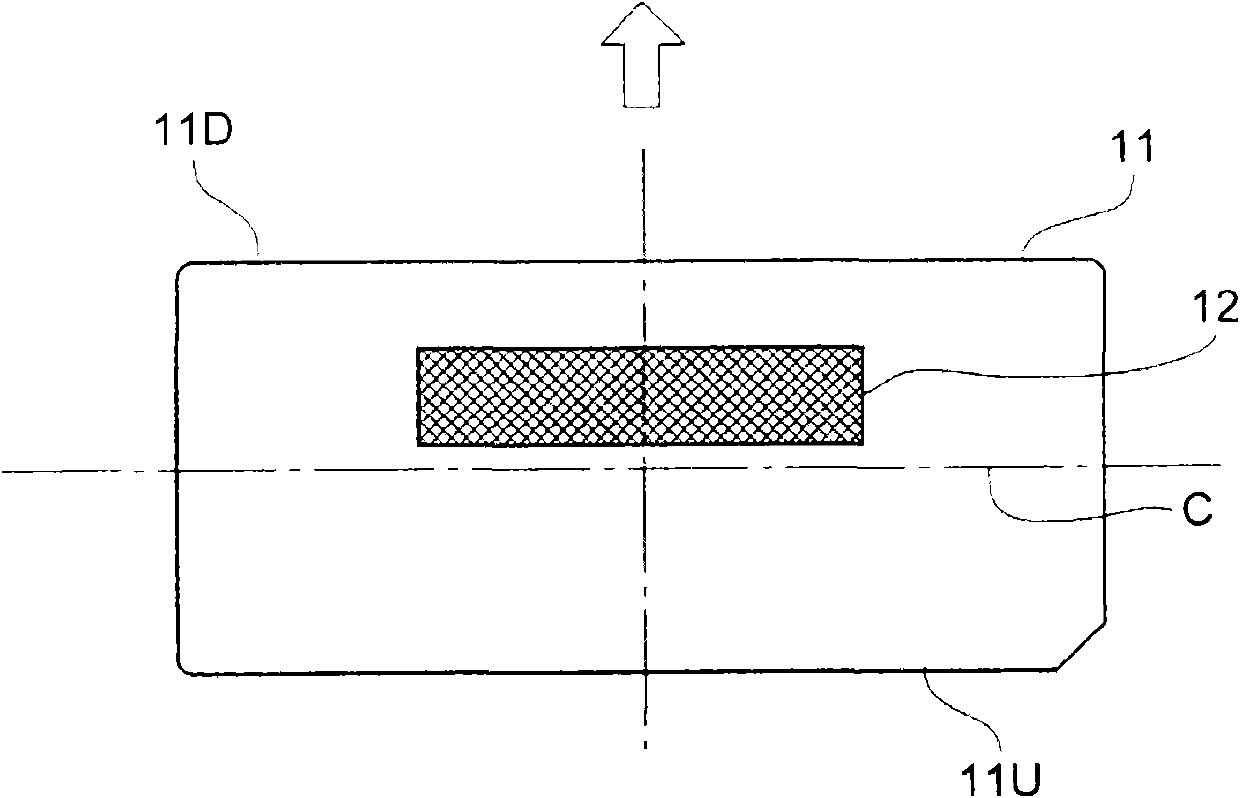

[0022] figure 2 It is an example of the recording medium 11, and the recording medium 11 has the RFID medium 12 which can realize RFID communication. Although not in figure 2 As shown in , the RFID medium 12 includes an IC chip that performs RFID communication and an antenna connected to the IC chip. Recording medium 11 configures RFID medium 12 from figure 2 The central portion C between the upstream end portion 11U and the downstream end portion 11D in the conveying direction indicated by the middle arrow is shifted toward the position of the downstream end portion 11D. The thickness of the RFID medium 12 in the recording medium 11 with an RF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com