Wear-resistant fabric adhesive tape

A technology for weaving fabrics and tapes, which is applied in the fields of wires or cable bundles, pressure-sensitive adhesive coatings, and cable harnesses. It can solve the problems of tape wear resistance or wear-resistant grade without mentioning, so as not to affect wear protection, Effect of narrow installation space and soft design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

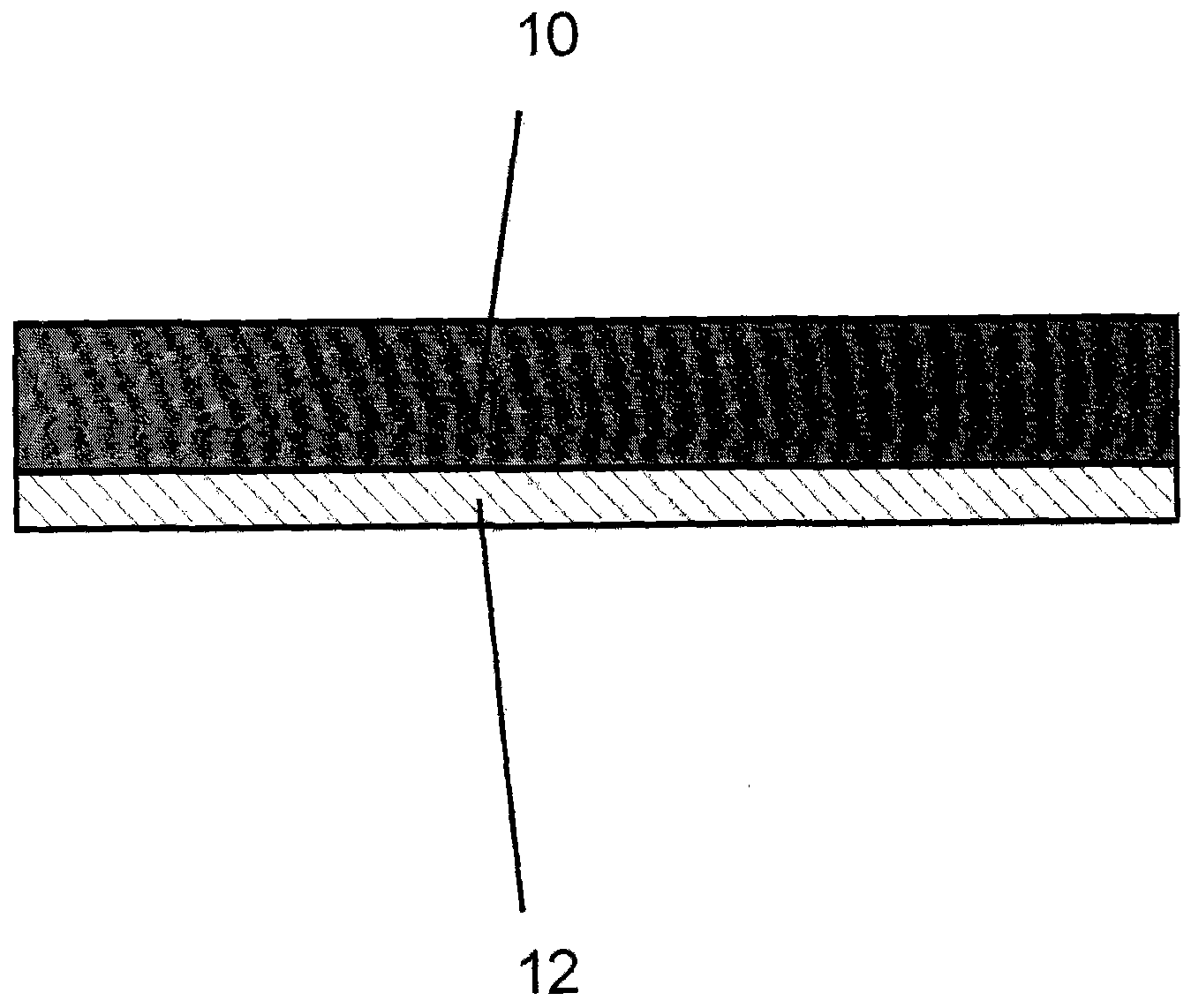

[0118] figure 1 An adhesive tape is shown in cross-section, consisting of a woven fabric carrier 10 to which a self-adhesive coating 12 is applied on one side.

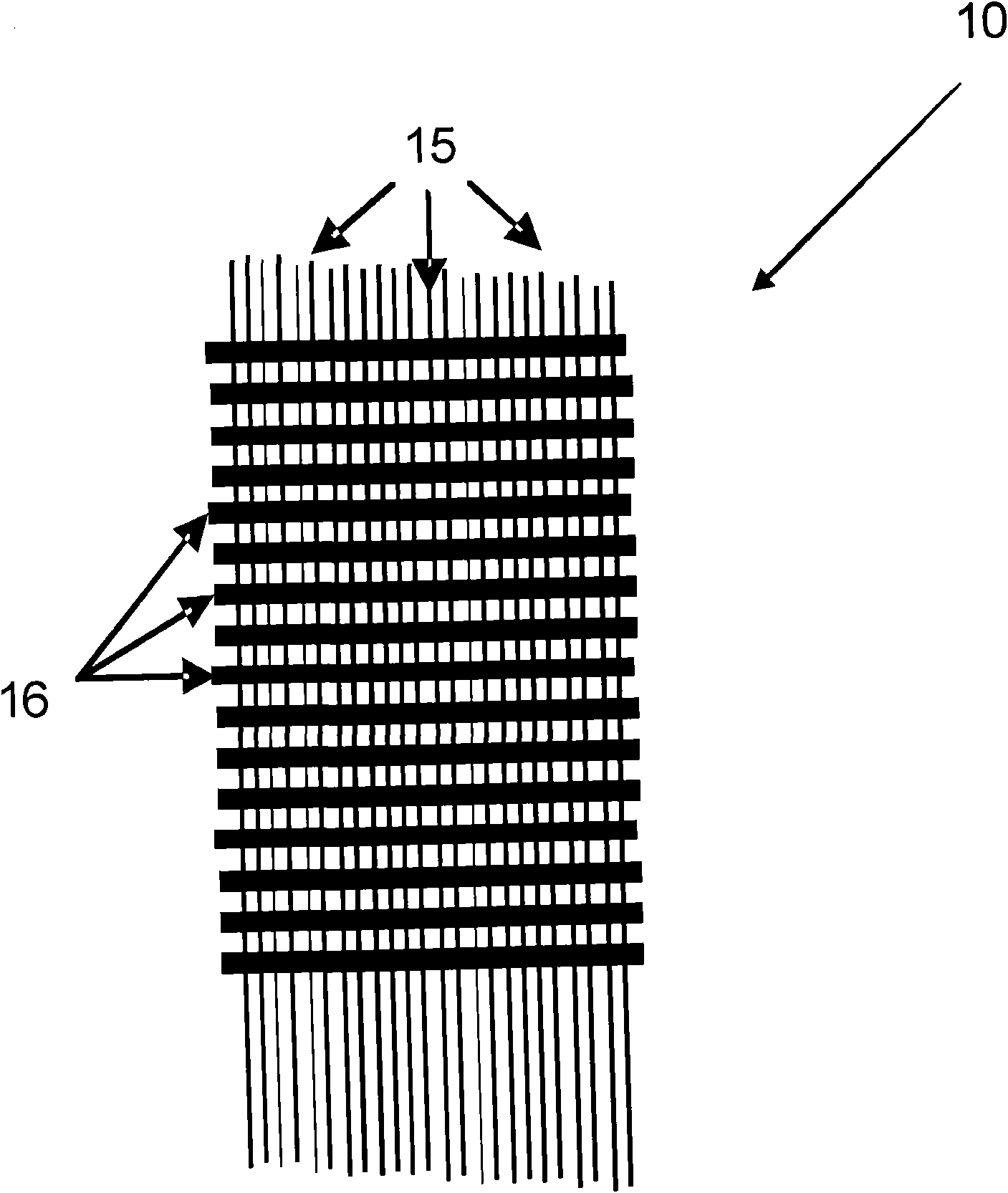

[0119] figure 2 The woven fabric forming the carrier 10 is shown in detail. The fabric is characterized in that the weft threads have a much greater thread weight than the warp threads.

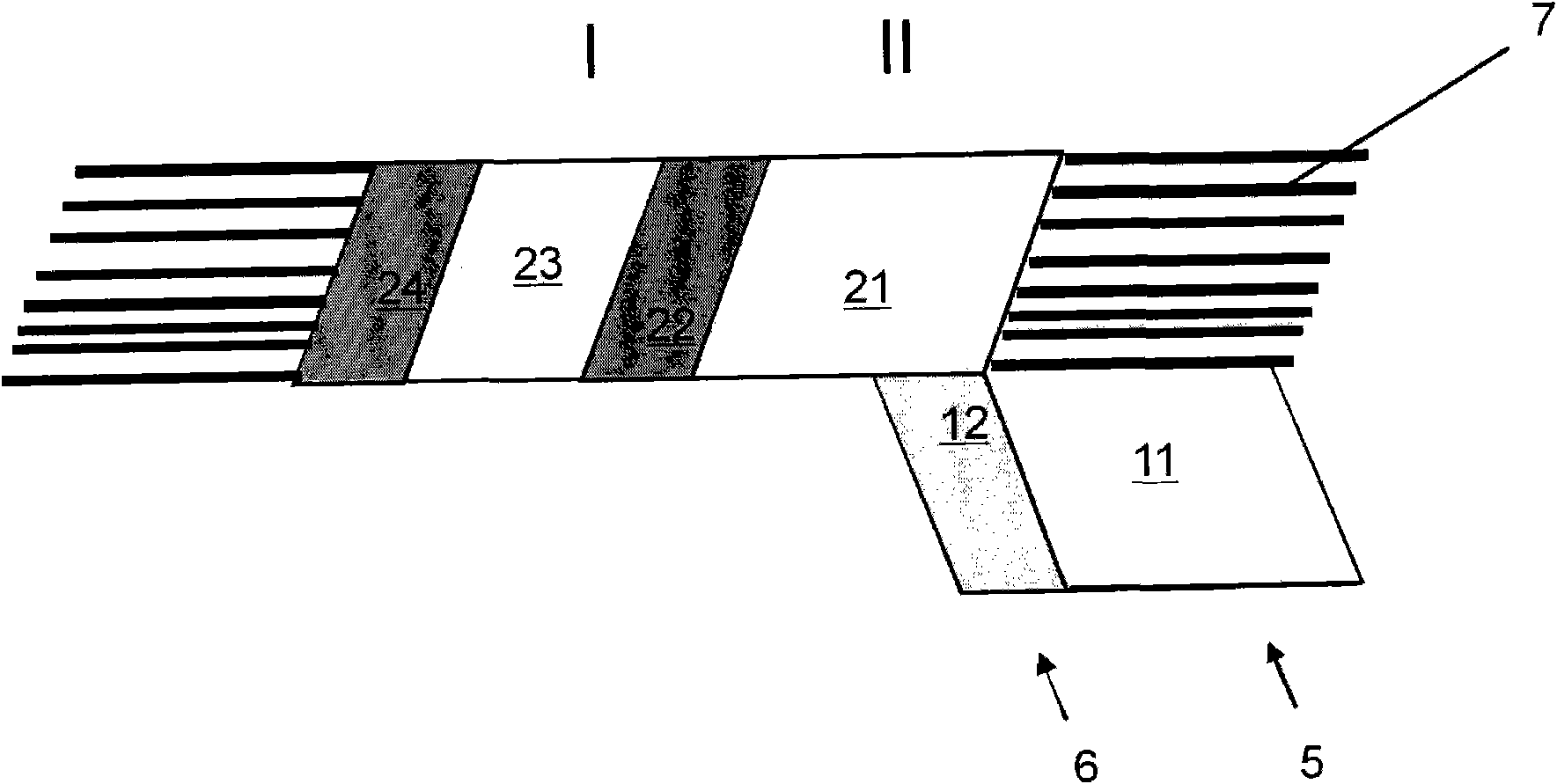

[0120] image 3 A section of a cable harness consisting of bundles of individual cables 7 wrapped with the adhesive tape of the invention is shown. The tape is guided in a helical motion around the cable harness.

[0121] The set of cable harnesses depicted shows two turns of tape, I and II. There will be more turns extending to the left, but they are not shown here.

[0122] On the adhesive coating there is a strip 5 on the sheath, thereby producing an adhesive strip 6 extending in the longitudinal direction of the tape. The non-adhesive areas 11 , 21 , 23 of the tape alternate with the adhesive areas 12 , 22 , 24 . (In con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com