Integrated binding and locating device of single-box double-chamber full span box girder reinforcing steel bar

A positioning device and a single-box technology, applied in the field of inner tube frames, can solve the problems of cumbersome installation and disassembly of inner tube frames, poor stability, and low work efficiency, and achieve the effects of improved worker safety protection, improved safety, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

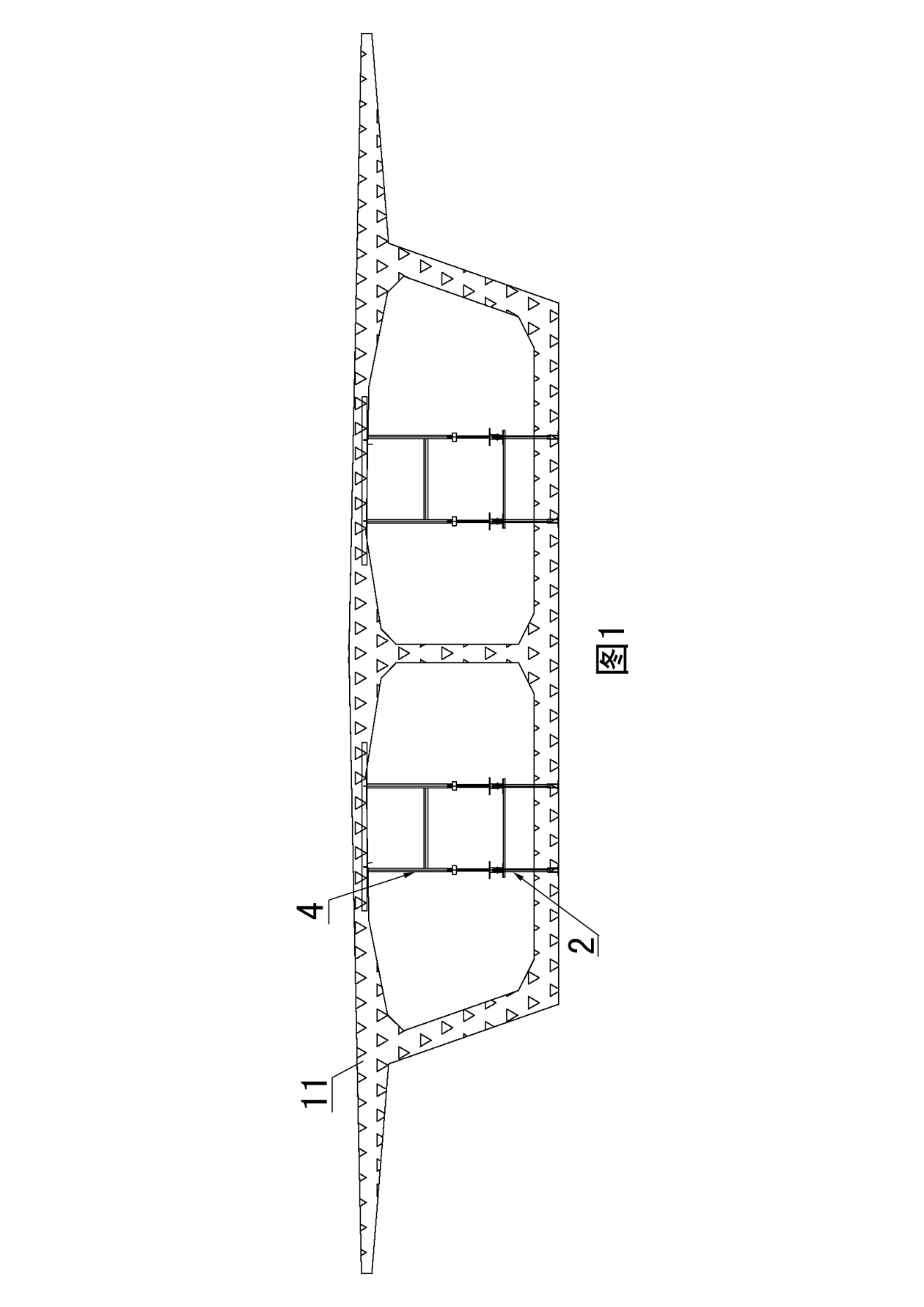

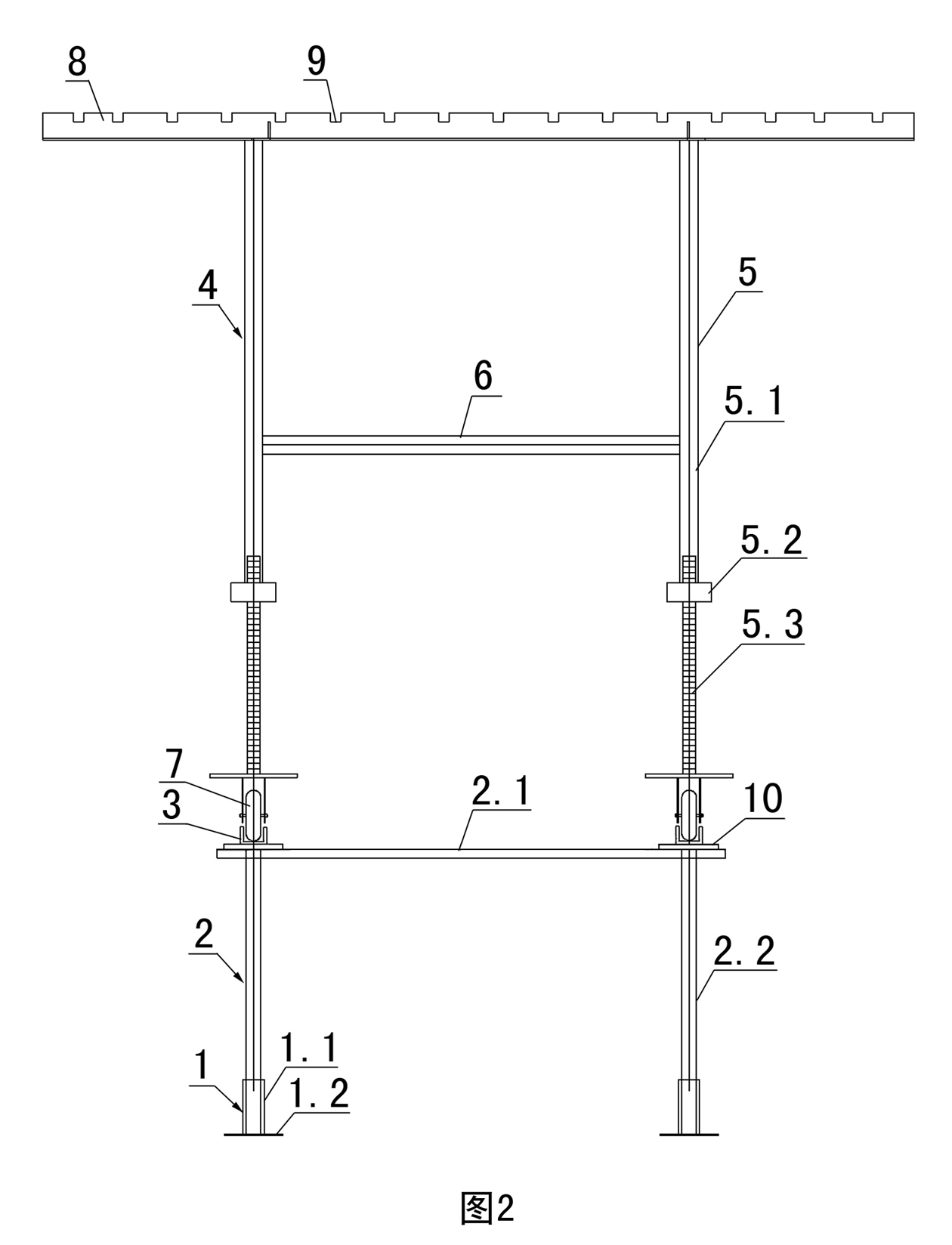

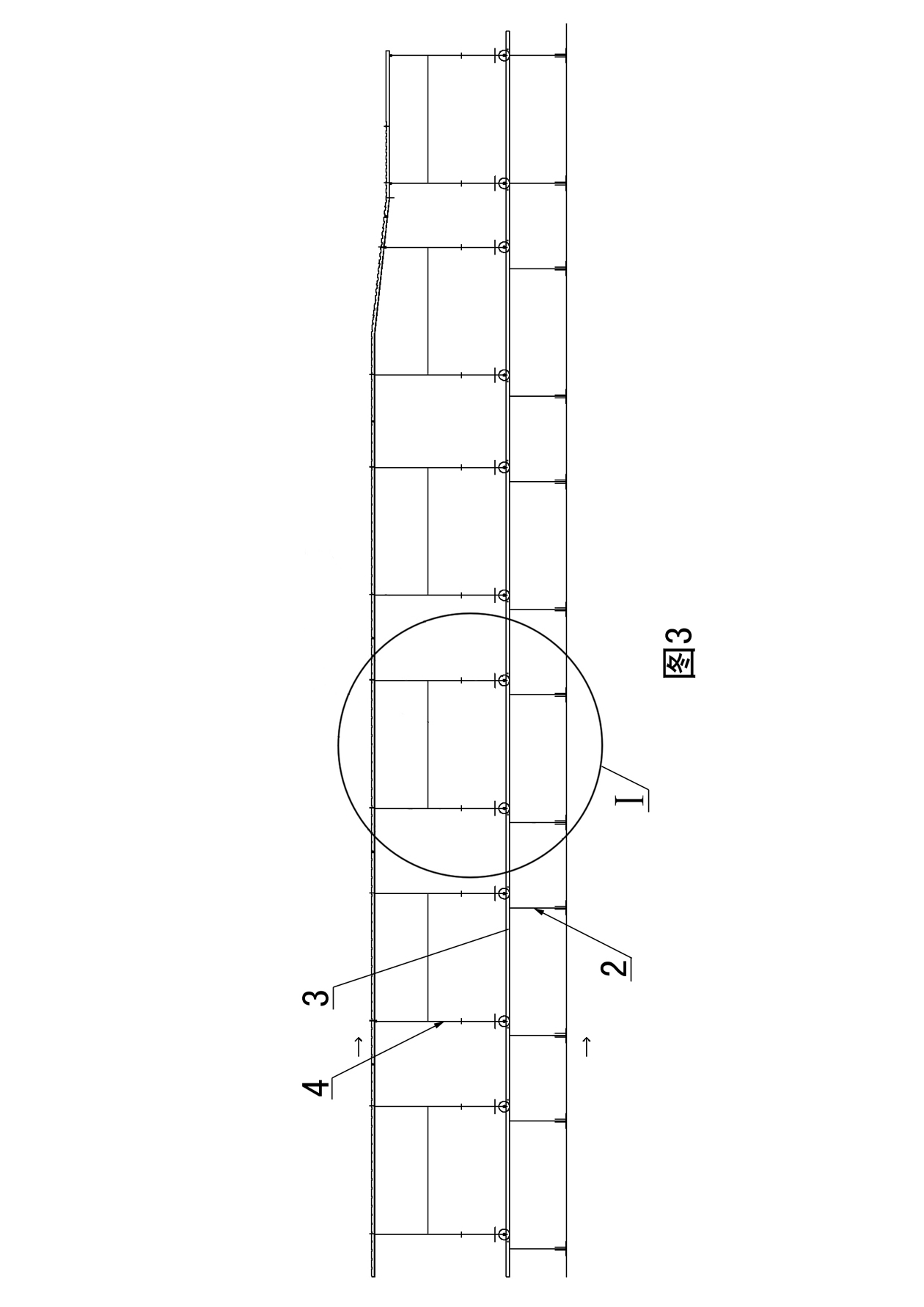

[0020] Examples see Figure 1-5 As shown, this single-box double-chamber full-hole box girder reinforcement integral binding positioning device includes two rows of inner tube frames fixed longitudinally on the ground, and each row of inner tube frames includes two rows of longitudinally distributed tubular fixing piles 1, inserted in The legs 2 in the two rows of tubular fixed piles 1, the two rows of longitudinal platforms 10 fixedly placed on the legs, the two rows of longitudinal chutes 3 detachably connected to the upper surfaces of the two rows of platforms 10, and the two rows of A row of support frames 4 on the chute 3, positioning holes 12 are provided on the side wall of the chute 3; The connecting rod 6 between them, the pulley 7 connected to the lower ends of the four vertical rods 5, and the well-shaped skeleton 8 fixedly connected to the upper ends of the four vertical rods 5, the skeleton 8 is fixedly connected by two horizontal shaped steels and two vertical sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com