Film stress measuring equipment and film stress measuring method

A technology of thin film stress and measuring equipment, which can be used in measuring devices, measuring and instruments by measuring the changing force of optical properties of materials when they are stressed, and can solve the problems of low degree of automation and low precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

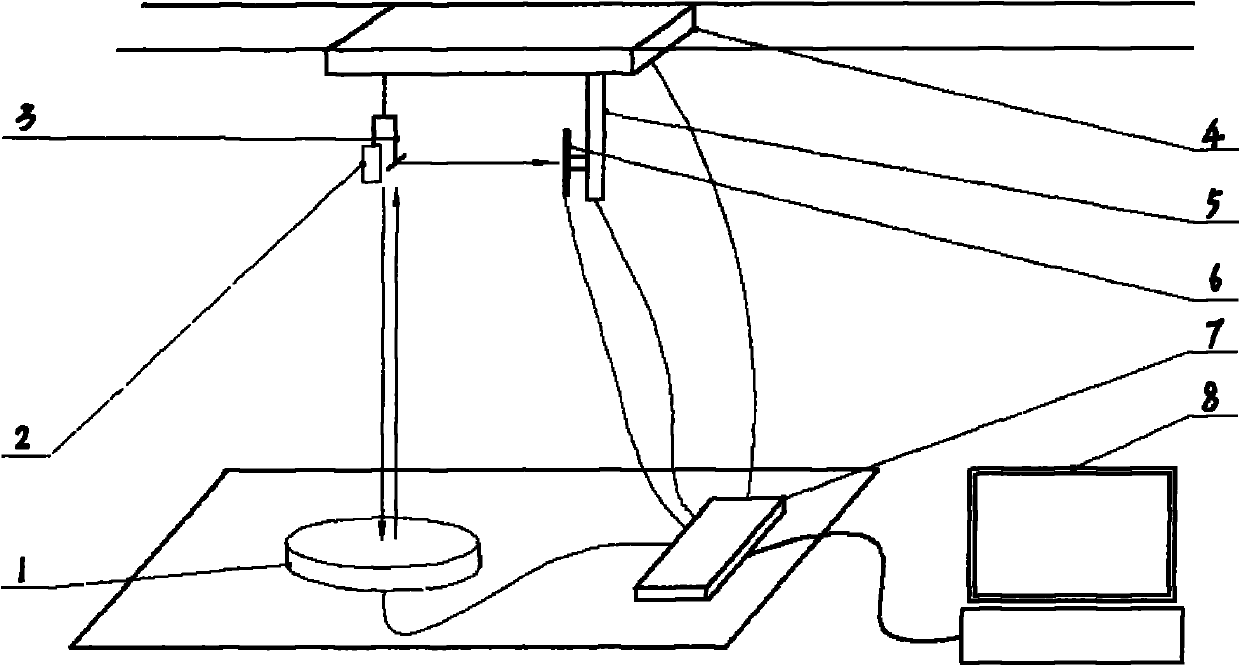

[0034] like figure 1 As shown, in the cuboid equipment case, the laser LED 2, the optical mirror 3, the linear slide rail 4, the detector 6, and the linear slide rail 5 are all connected to the top surface of the equipment case, and the linear slide rail 5 is placed on the linear slide rail 4 below and connected vertically, the tray 1 and the A / D data acquisition card 7 are placed on the inner bottom surface of the equipment case, the tray 1, the A / D data acquisition card 7, the linear slide rail 4, the detector 6, and the linear slide rail 5 All are connected with the computer 8 outside the box of cuboid equipment through circuit. Wherein, the linear slide rail 4 is parallel to the surface of the tray 1 and is located directly above the tray 1 . The linear slide rail 4 is connected with a micro stepping motor outside the equipment through a circuit, and is controlled by the stepping motor. The tray 1 is connected with a micro stepping motor outside the device through a circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com