Detection system of piezoelectric material

A detection system and piezoelectric material technology, which can be used in measuring devices, measuring electrical variables, instruments, etc., and can solve the problem of no piezoelectric material testing device.

Active Publication Date: 2011-04-20

CRM ICBG (WUXI) CO LTD

View PDF1 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there is currently no testing device for piezoelectric materials on the market.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

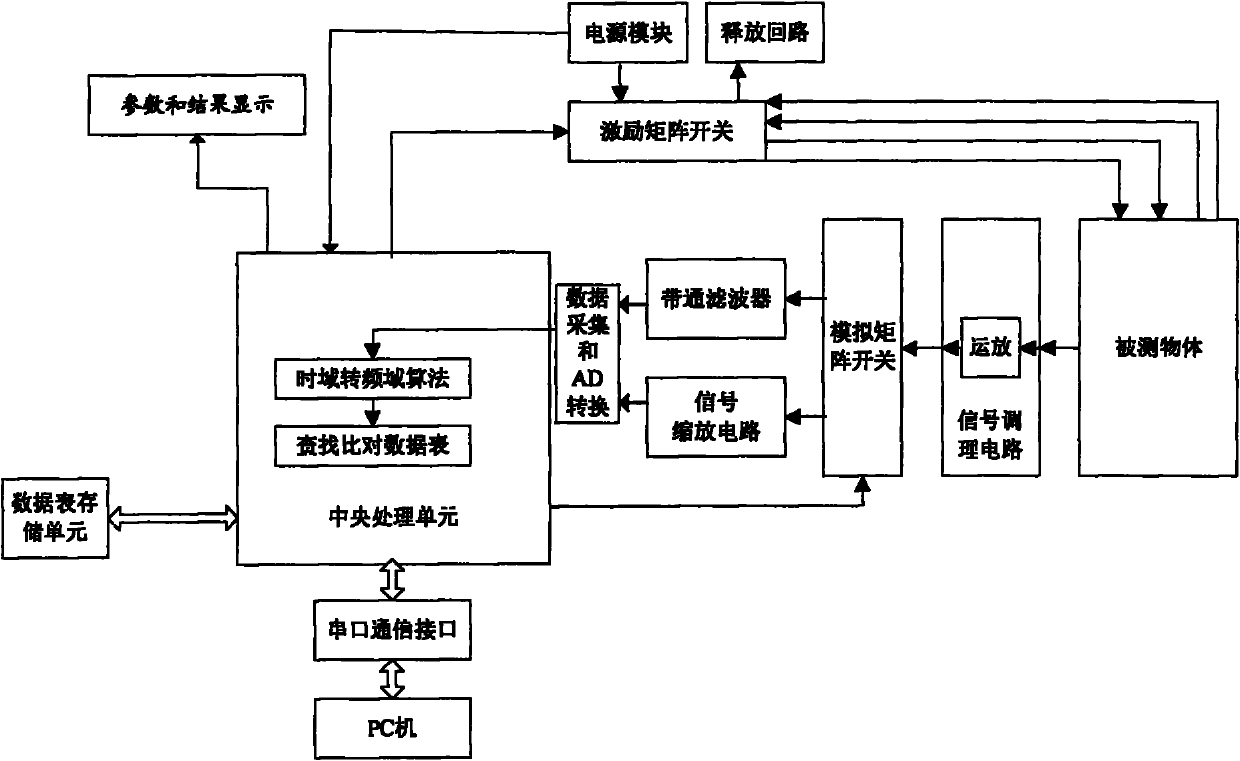

[0054] The second embodiment only replaces the digital signal processing (DSP) chip in the first embodiment with a central processing unit and a data acquisition and AD conversion unit to realize all functions of the digital signal processing (DSP) chip. Other parts and their connections, signal processing methods and principles in the two embodiments are the same, and will not be repeated here.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Login to View More

Abstract

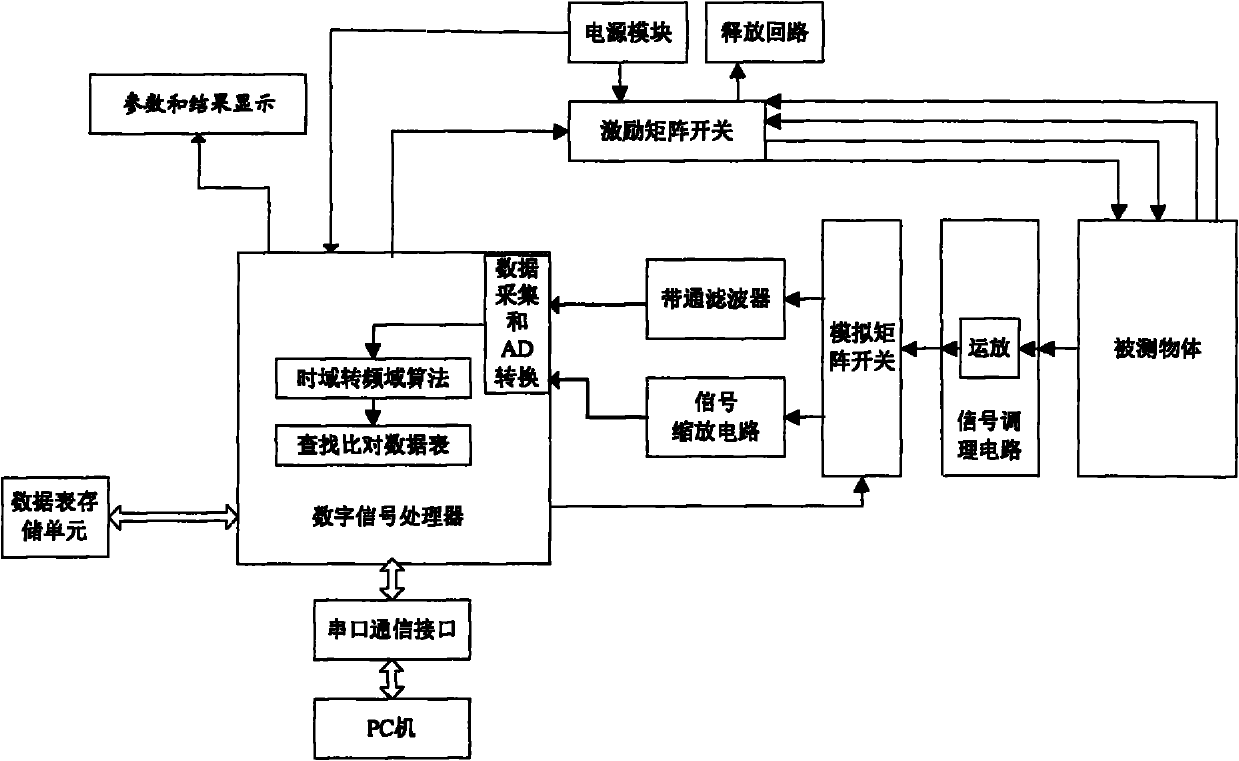

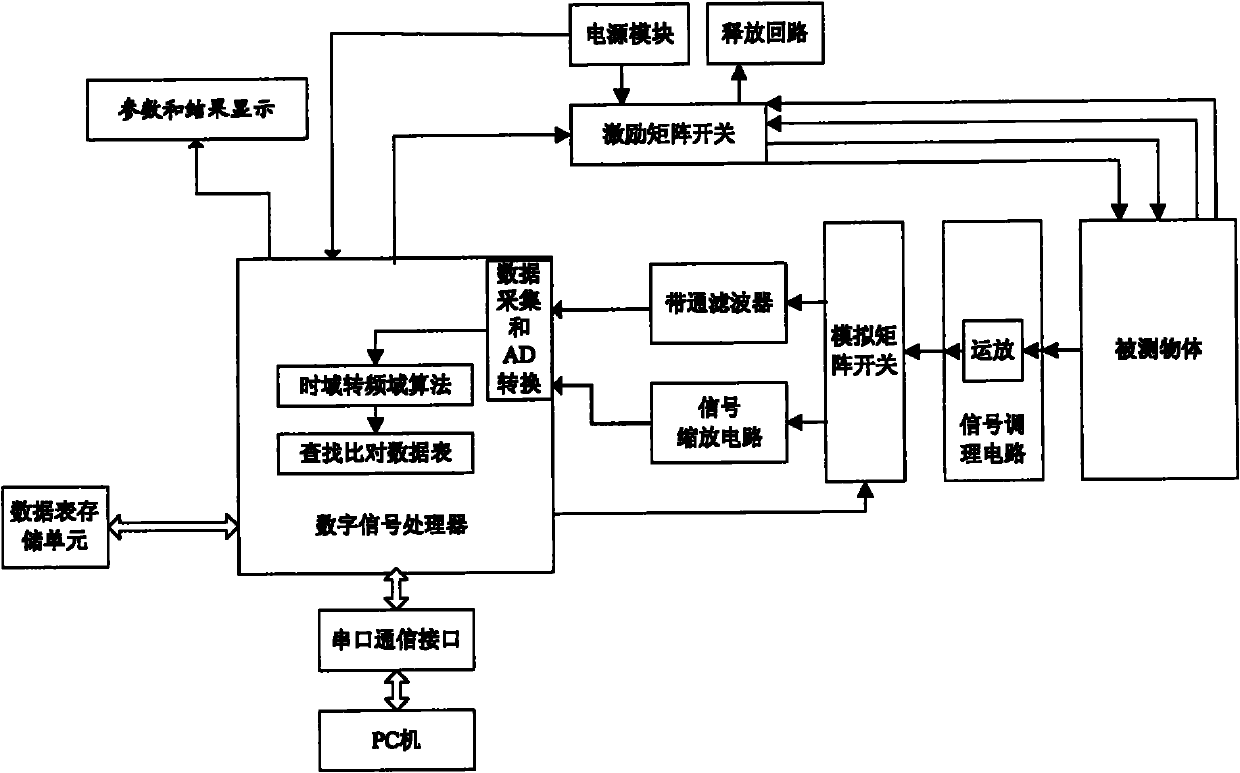

The invention relates to a detection system of a piezoelectric material, which comprises a power module, a digital signal processing (DSP) chip, an excitation matrix switch, a signal conditioning circuit, an analog matrix switch, a band pass filter, a signal scaling circuit, a personal computer (PC), a serial communication interface and a data table storage unit, or a central processing unit, a data acquisition and analog-digital (AD) conversion unit are utilized to replace the DSP chip to achieve the full functions of the DSP chip. The system can reflect the characteristics of the piezoelectric material by detecting the charge and discharge characteristics and resonance characteristics (LC characteristics) of excitation response in the circuit, and the characteristics of the piezoelectric material are compared with the set standard values, thereby selecting the piezoelectric material meeting the preset requirements. The system adopts the digital method and utilizes high-speed data acquisition to improve the sampling intensity of charge and discharge characteristic signals, thereby improving the success rate of selection; and the time sampling on resonant characteristic signals is carried out, the time domain is converted into the frequency domain through the discrete forurier transform (DFT), and the processing of resonant characteristic signals in the frequency domain is favorable for flexibly removing interferential components, thereby improving the stability and reliability of the system.

Description

technical field [0001] The invention belongs to the field of electronic control testing and relates to a piezoelectric material detection system. Background technique [0002] Piezoelectric material refers to a material that generates a voltage between its two ends when subjected to pressure. Piezoelectric materials are characterized by piezoelectric effect, that is, when subjected to pressure, a voltage will appear between the two ends and the amount of charge is proportional to the pressure. The mechanism of the piezoelectric effect is: the crystal with piezoelectricity has low symmetry. When it is deformed by an external force, the relative displacement of the positive and negative ions in the unit cell makes the positive and negative charge centers no longer overlap, resulting in macroscopic polarization of the crystal, while The surface charge surface density of the crystal is equal to the projection of the polarization intensity on the surface normal direction, so whe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01R29/22

Inventor 陶洪平

Owner CRM ICBG (WUXI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com