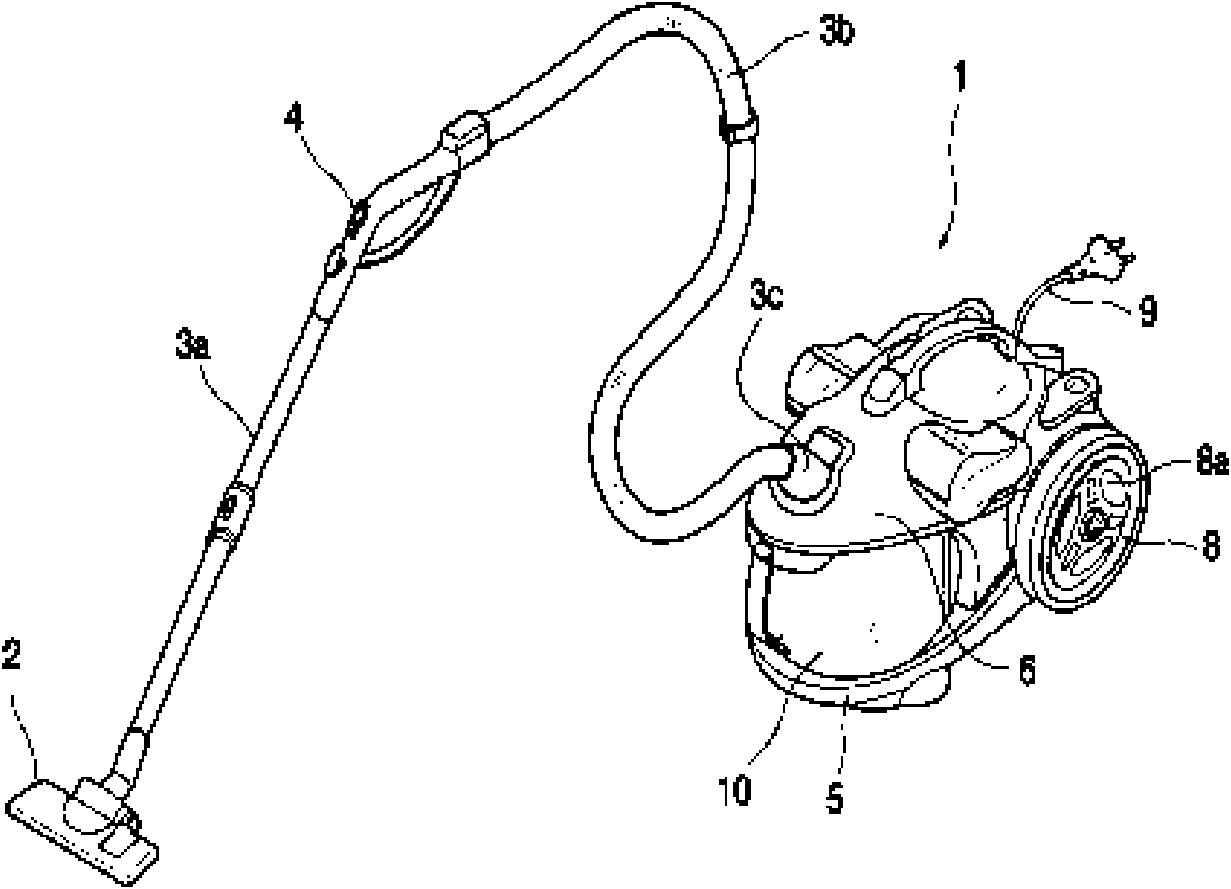

Motor cover for dust collector

A vacuum cleaner and motor cover technology, which is applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of sharp and harsh noise, and the control effect of motor noise is not obvious, and achieve the effect of good user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

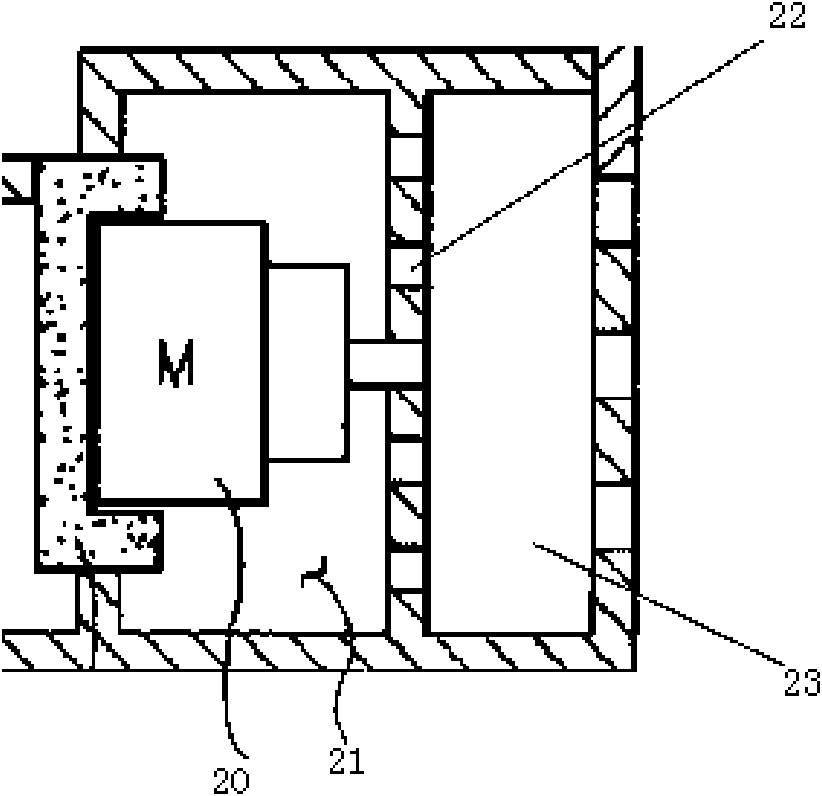

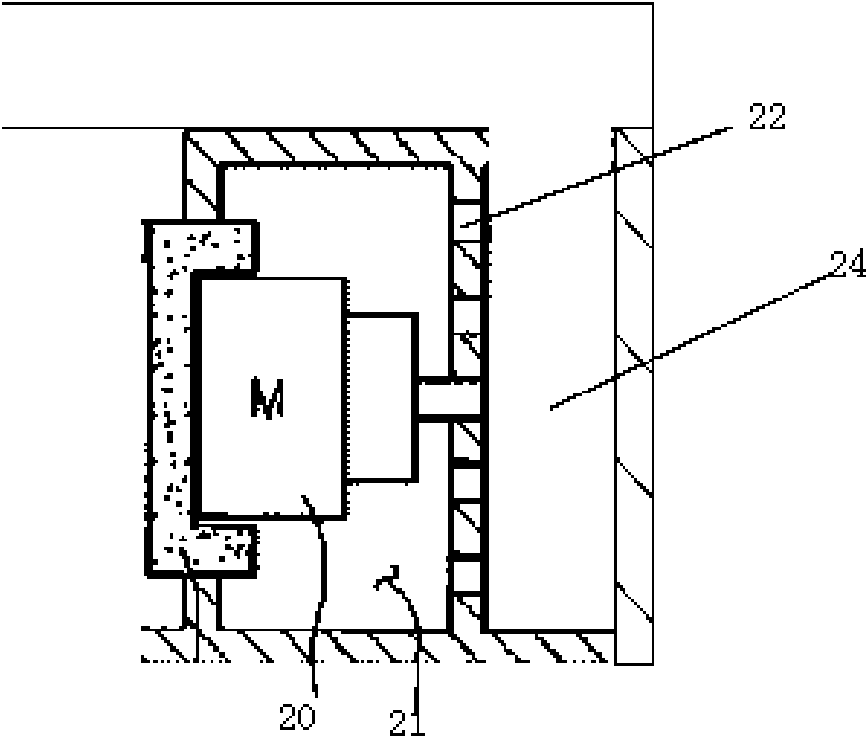

[0037] The present invention is described in detail below with reference to accompanying drawing and embodiment:

[0038] Figure 4 It is an exploded schematic view of the motor cover of the vacuum cleaner of the present invention; Figure 5 It is a sectional view of the motor cover of the vacuum cleaner of the present invention; Image 6 It is a structural schematic diagram of the sleeve in the motor cover of the vacuum cleaner of the present invention; Figure 7 It is a cross-sectional view of the sleeve in the motor cover of the vacuum cleaner of the present invention.

[0039] like Figure 4 to Figure 7As shown, the motor cover of the vacuum cleaner of the present invention is arranged inside the body of the vacuum cleaner, the motor 20 of the vacuum cleaner is fixed, and the flow direction of the air discharged from the motor is guided, wherein the casing 30 and the casing cover 31 provided with an air inlet form the appearance of the motor cover , surround the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com