Pump tappet

A technology for pumps and rollers, applied in the field of pump tappets, can solve the problems of poor end lubrication of roller bearings and wear of outer ring 108, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

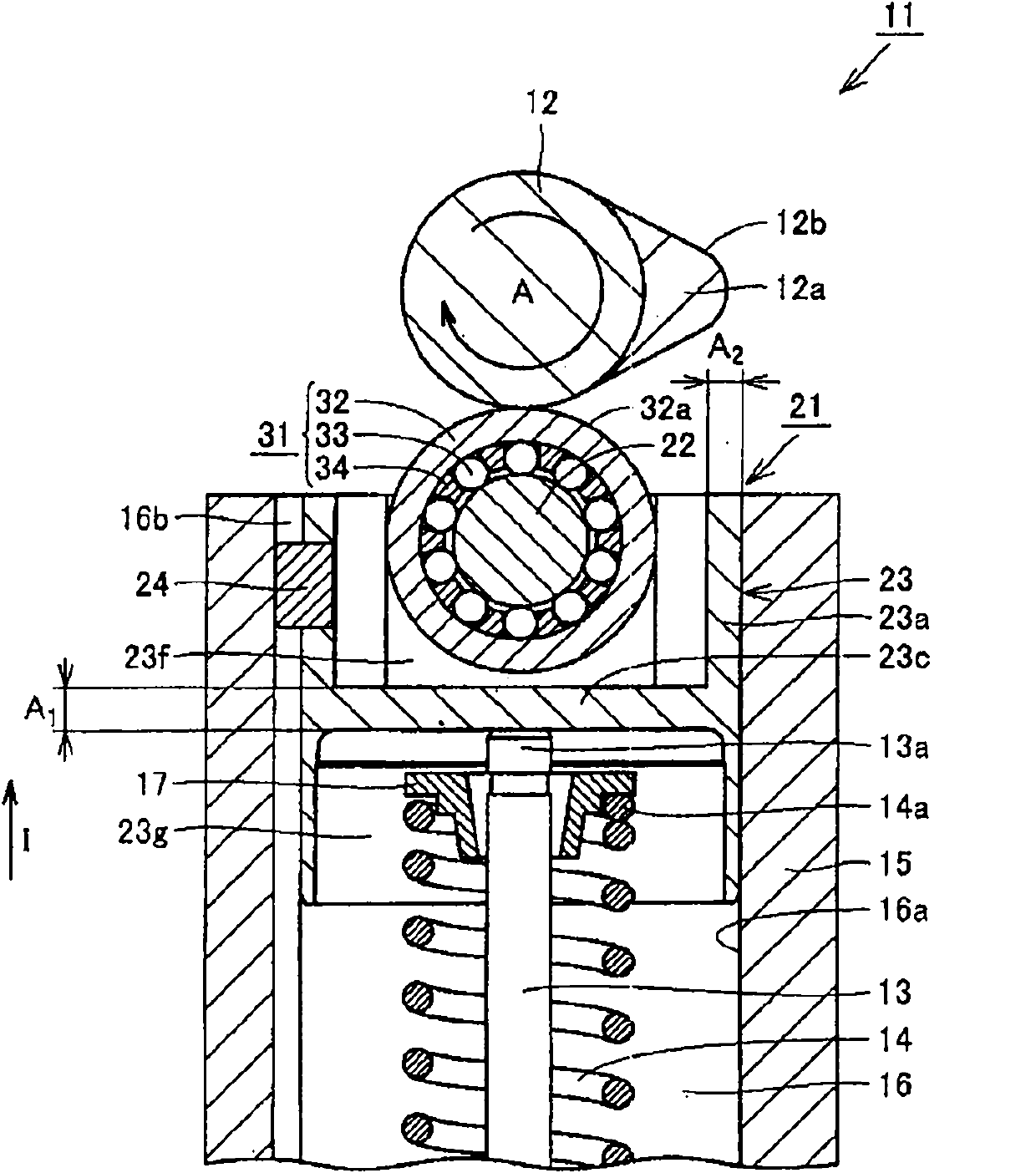

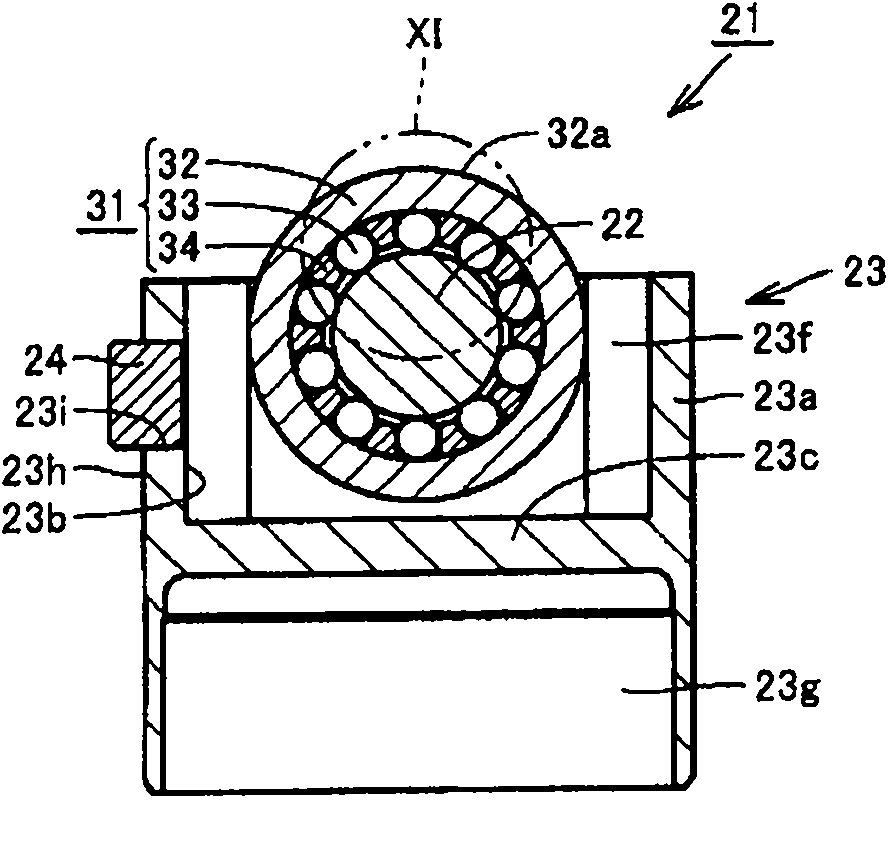

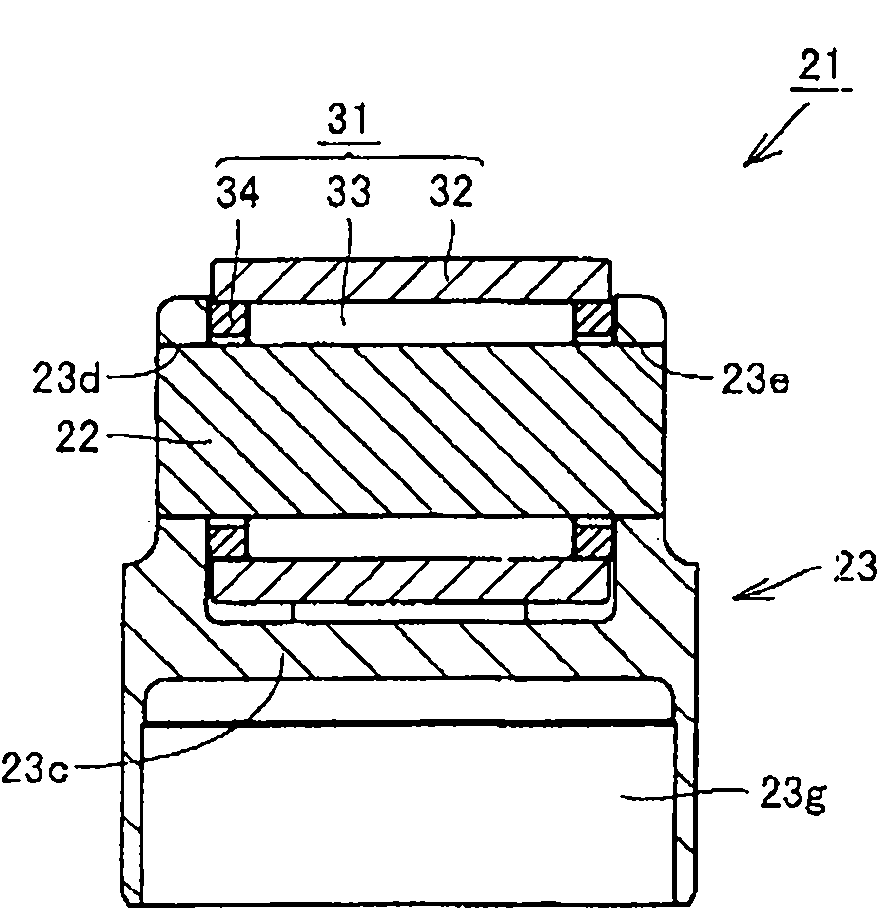

[0079] Embodiments of the present invention will be described below with reference to the drawings. figure 1 It is a cross-sectional view showing part of a high-pressure pump including a pump tappet (hereinafter simply referred to as a "tappet") according to an embodiment of the present invention. figure 2 as well as image 3 yes figure 1 Cutaway view of a lifter included in the high pressure pump shown. Figure 4 yes figure 2 as well as image 3 A schematic perspective view of the lifter shown. Figure 5 From Figure 4 View in the direction of the arrow V Figure 4 A diagram of the tappet is shown. Figure 6 From Figure 4 View in the direction of the arrow VI Figure 4 A diagram of the tappet is shown. Figure 7 From Figure 4 View in the direction of the arrow VII Figure 4 A diagram of the tappet is shown. Figure 8 From Figure 4 View in the direction of arrow VIII in Figure 4 A diagram of the tappet is shown. and, figure 2 equivalent to Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com