Method for maintaining normal unloading of mining dump truck in winter and exhaust and heating system

A mining dump truck and heating system technology, applied in heating/cooling equipment, vehicle parts, transportation and packaging, etc., can solve problems such as difficult manual cleaning, low overall utilization of the box, and unloading of goods, so as to reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

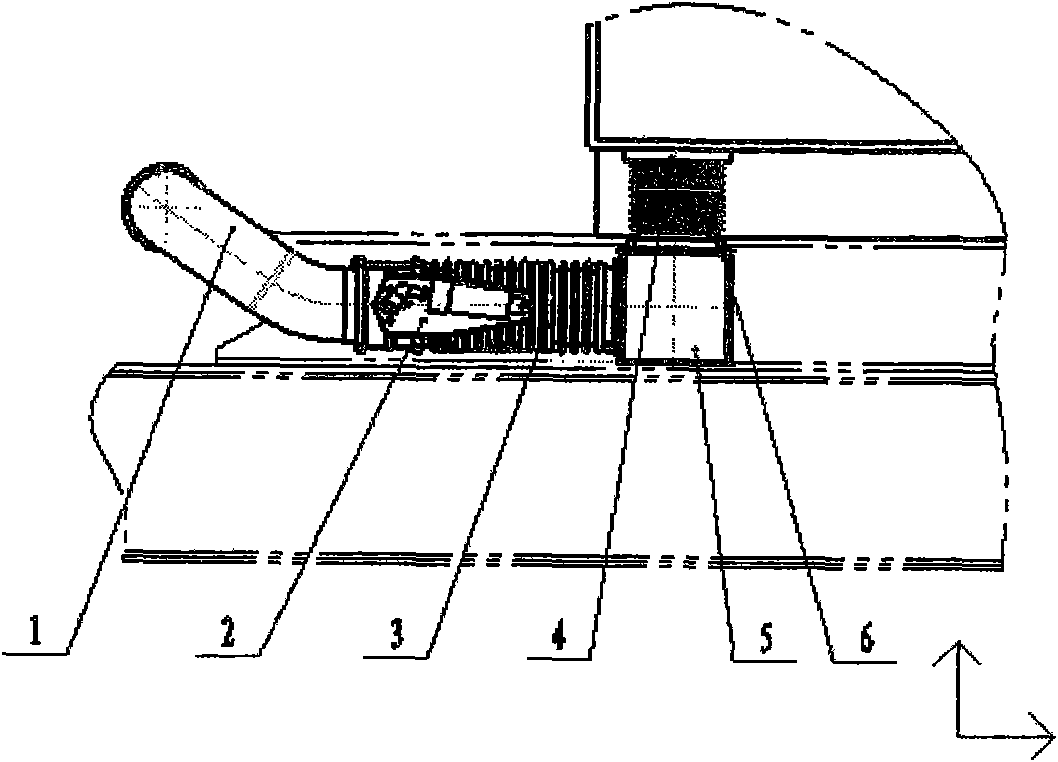

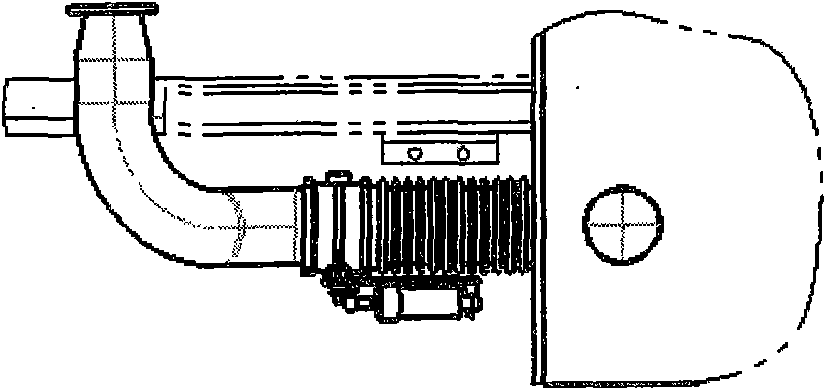

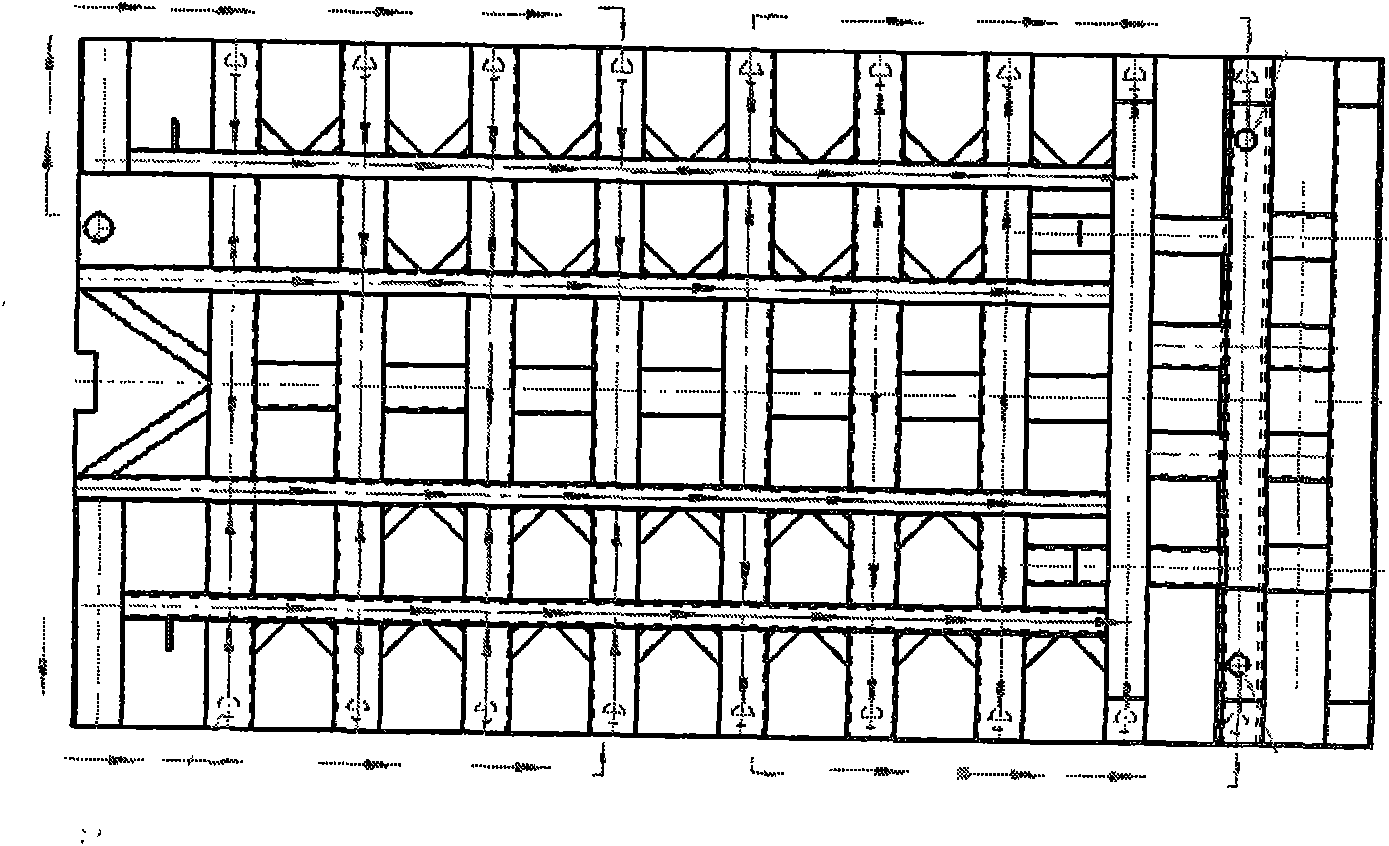

[0010] Such as figure 1 , 2 , 3 gives the specific implementation of the present invention.

[0011] Maintaining the normal unloading method of mining dump trucks in winter is to use the heat of the exhaust gas discharged from the engine to heat the bottom plate to prevent the cargo on the bottom plate from freezing at the edges and corners of the car body. Remove the muffler on the exhaust pipe of the engine, and connect the outlet end of the exhaust pipe to the underframe assembly of the vehicle to supply heat to the bottom plate.

[0012] The exhaust and heating system of the floor of a mining dump truck is connected with an exhaust butterfly valve 2 at the outlet end of the exhaust pipe 1. The exhaust butterfly valve 2 is connected to the vehicle chassis underframe assembly through the pipeline, and the underframe assembly The joints of the cross beam and the longitudinal beam are connected to form a continuous closed air path, and two exhaust ports are opened on the cross beam...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap