Jib arm structure of lorry-mounted crane

A truck-mounted crane and crane technology, applied in cranes and other directions, can solve the problems of low production efficiency, unguaranteed product quality, angle deviation, etc., and achieve the effects of reducing labor intensity, product quality assurance, and control cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

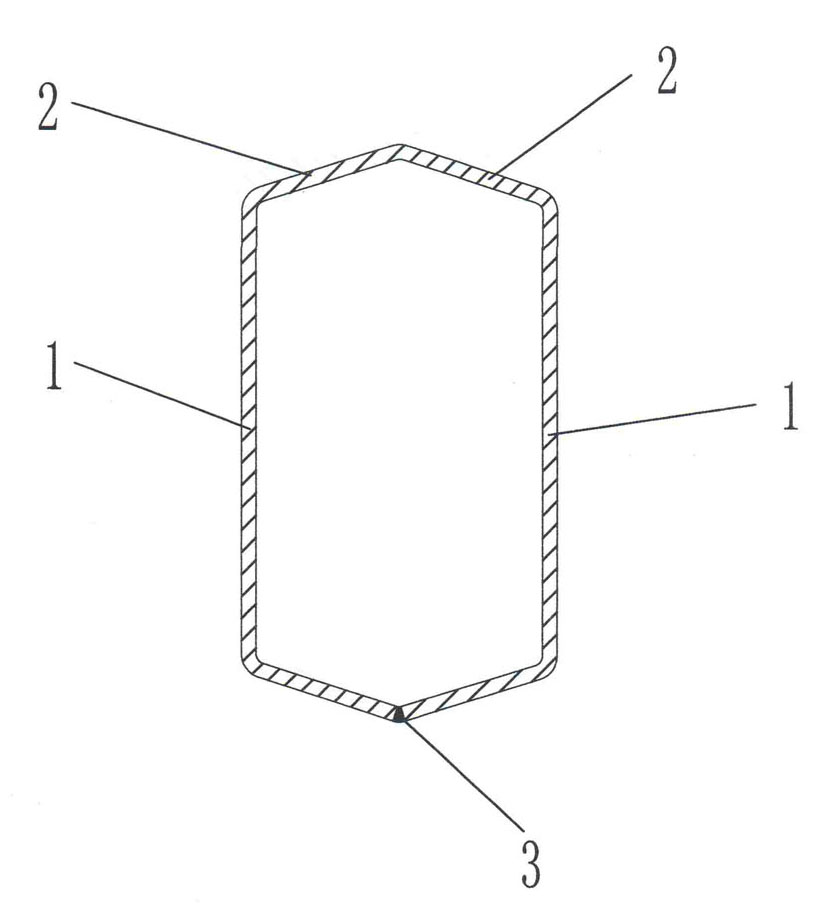

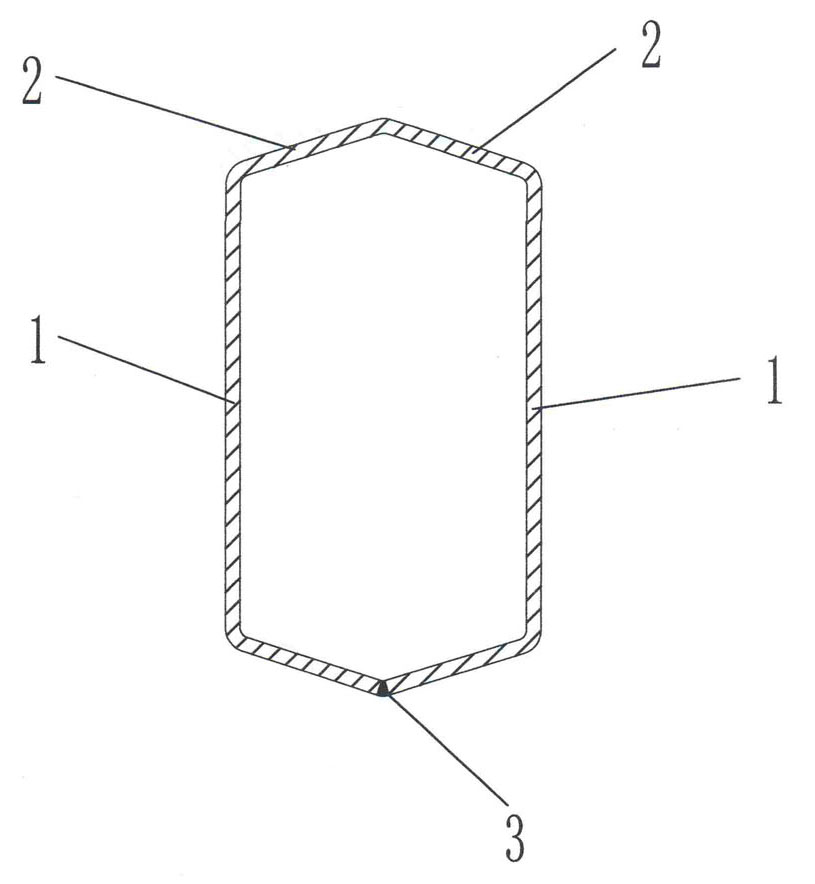

[0013] see figure 1 , a truck-mounted crane boom structure, the steel plate is bent into a crane boom with a polygonal cross section by a bending machine, and the two corresponding short sides 2 at the polygon opening are connected by welding to make the polygon The long side 1 and the short side 2 are connected as a whole.

[0014] In this embodiment, the boom structure of the truck-mounted crane is that the steel plate is bent once by a bending machine into a crane boom with a hexagonal cross-section. The two corresponding short sides 2 at the opening of the hexagon The spaces are connected by welding, so that the long side 1 and the short side 2 of the hexagon are integrated. Weld seam 3 is to use tooling to close the seam mouth, measure and correct the size of each part to be correct, and spot weld firmly.

[0015] The accuracy of the boom of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap