Aluminum alloy composite tube pre-brazing layer material

A composite pipe and pre-brazing technology, applied in the field of deformed aluminum alloy materials, can solve the problems of insufficient sealing performance and insufficient fluidity, and achieve the effects of good welding performance, excellent welding fluidity, and reducing welding leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Aluminum alloy composite pipe pre-brazed layer material, its chemical composition weight percentage is:

[0015] Silicon 8.6~11.5%;

[0016] Zinc 0.9~1.2%;

[0017] Iron 0.1~0.7%;

[0018] The rest is aluminum.

[0019] Its components can also be: 8.83-11.2% of silicon, 0.95-1.17% of zinc, 0.19-0.65% of iron, and the rest is aluminum.

[0020] Its components can further be: 10.2% of silicon, 1.01% of zinc, 0.41% of iron, and the rest is aluminum.

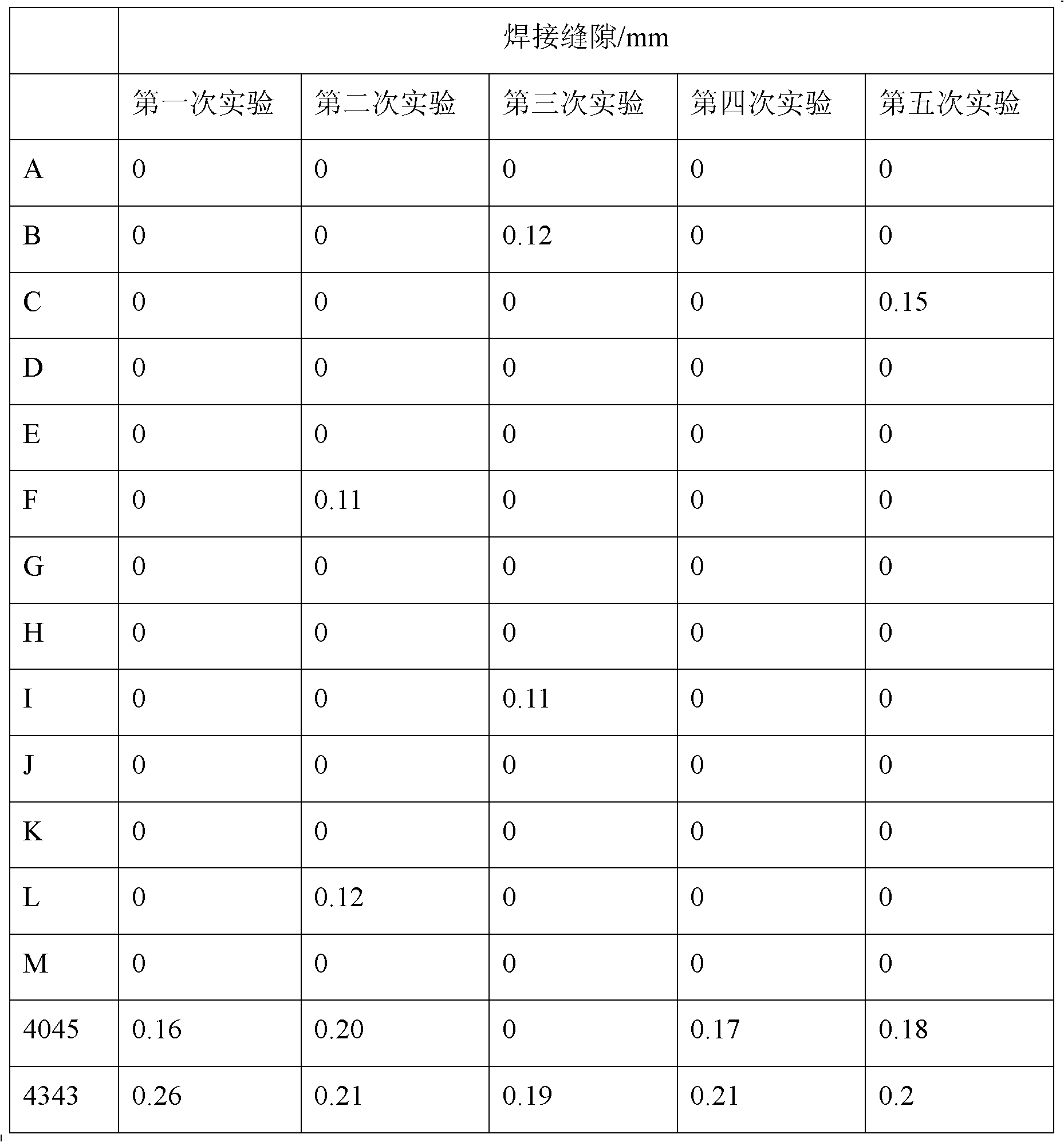

[0021] In the new alloy, prepare a composite aluminum tube A of a specification according to the upper limit of all components, prepare the same product B according to the lower limit of the components, and prepare the same specification products C, D, E, F, G, H, I, J, K, L, M, take 4343, 4045 alloy components are also extruded products of the same specification, their chemical composition weight percentage is:

[0022]

silicon

iron

zinc

aluminum

A

11.50

0.70

1.20

marg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com