Small-size hydraulic automatic tamping machine and intelligent control method

A tamping machine and hydraulic technology, applied to roads, tracks, ballast layers, etc., can solve the problems of high labor intensity of operators, increased workload of railway maintenance, lack of safety and humanization, etc., and achieve operability Effects of enhancing, reducing labor intensity, improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

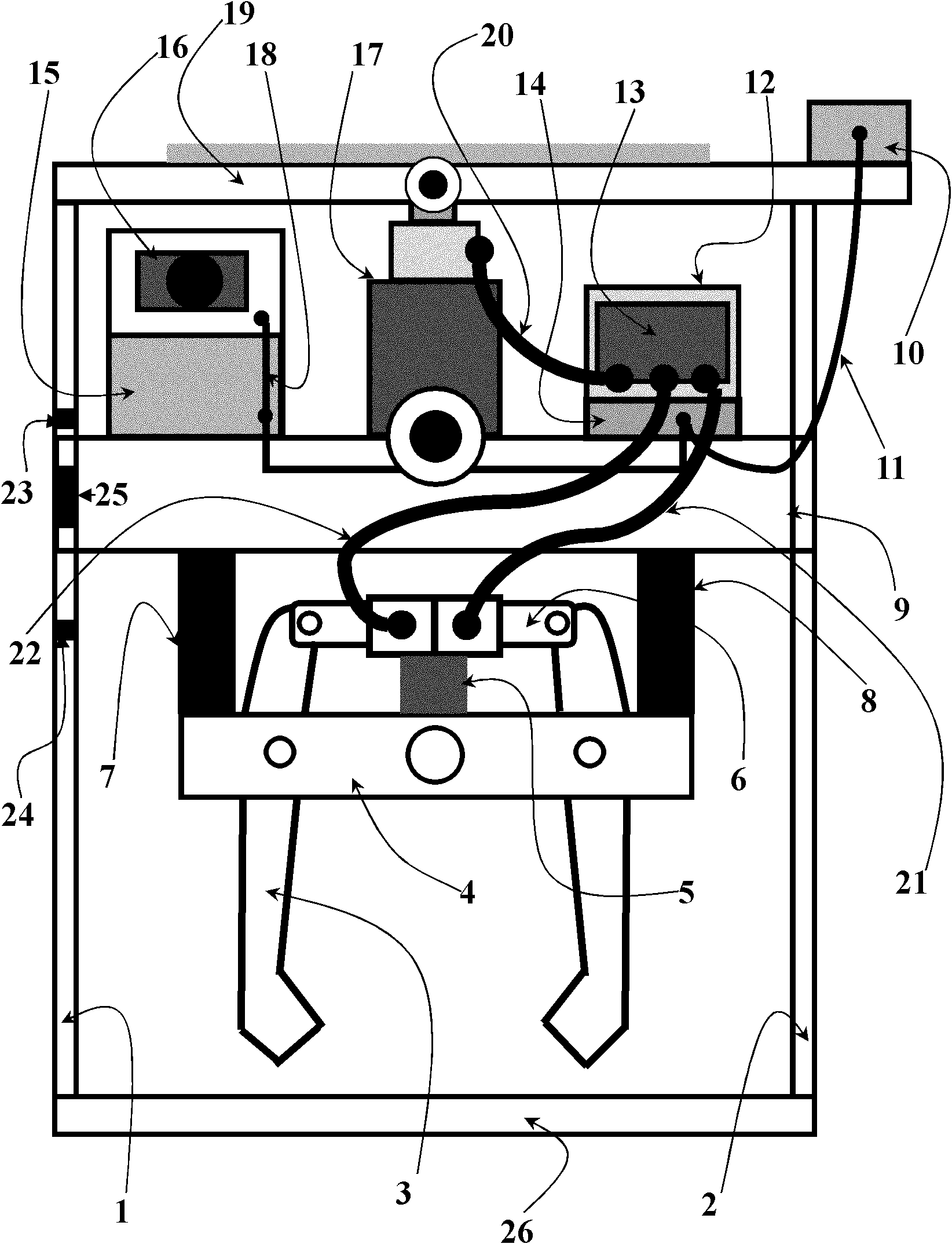

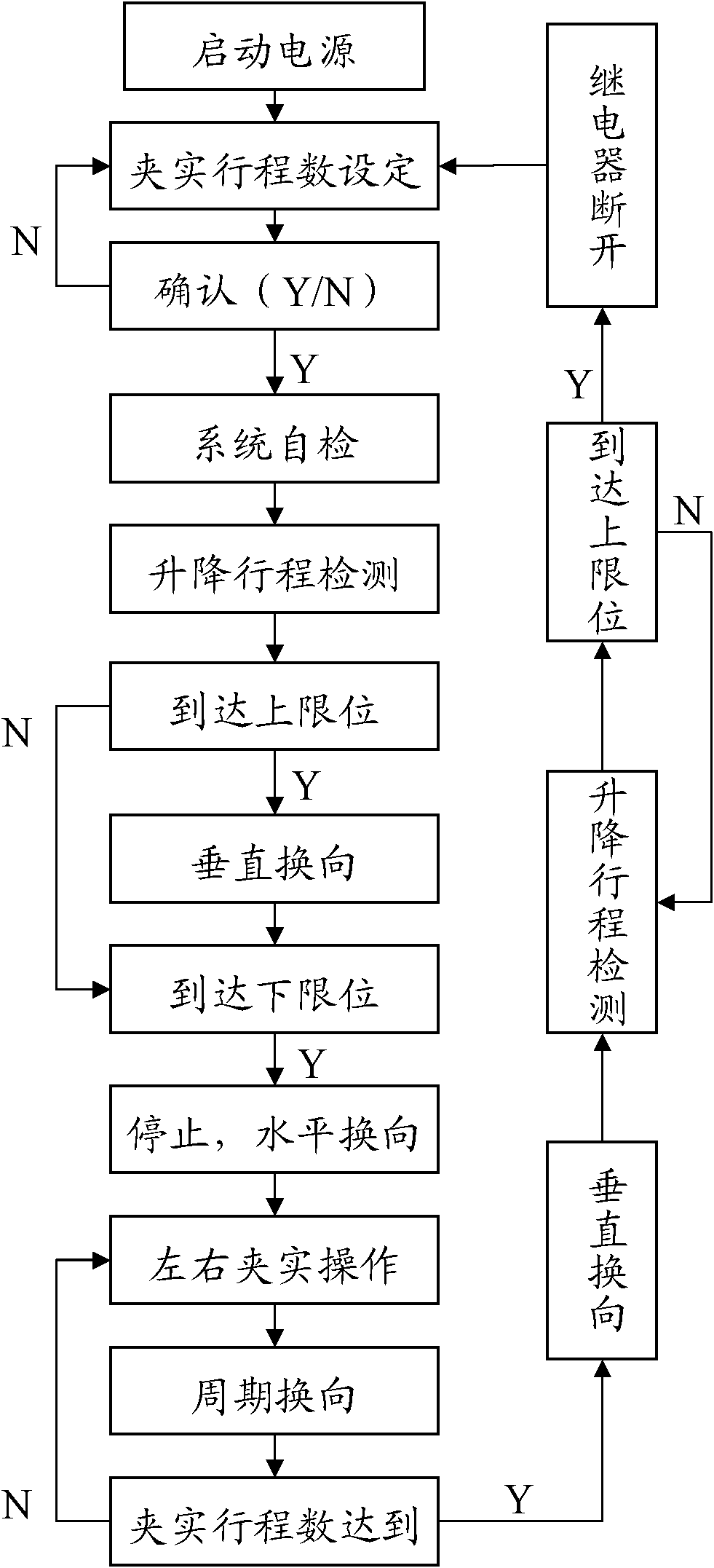

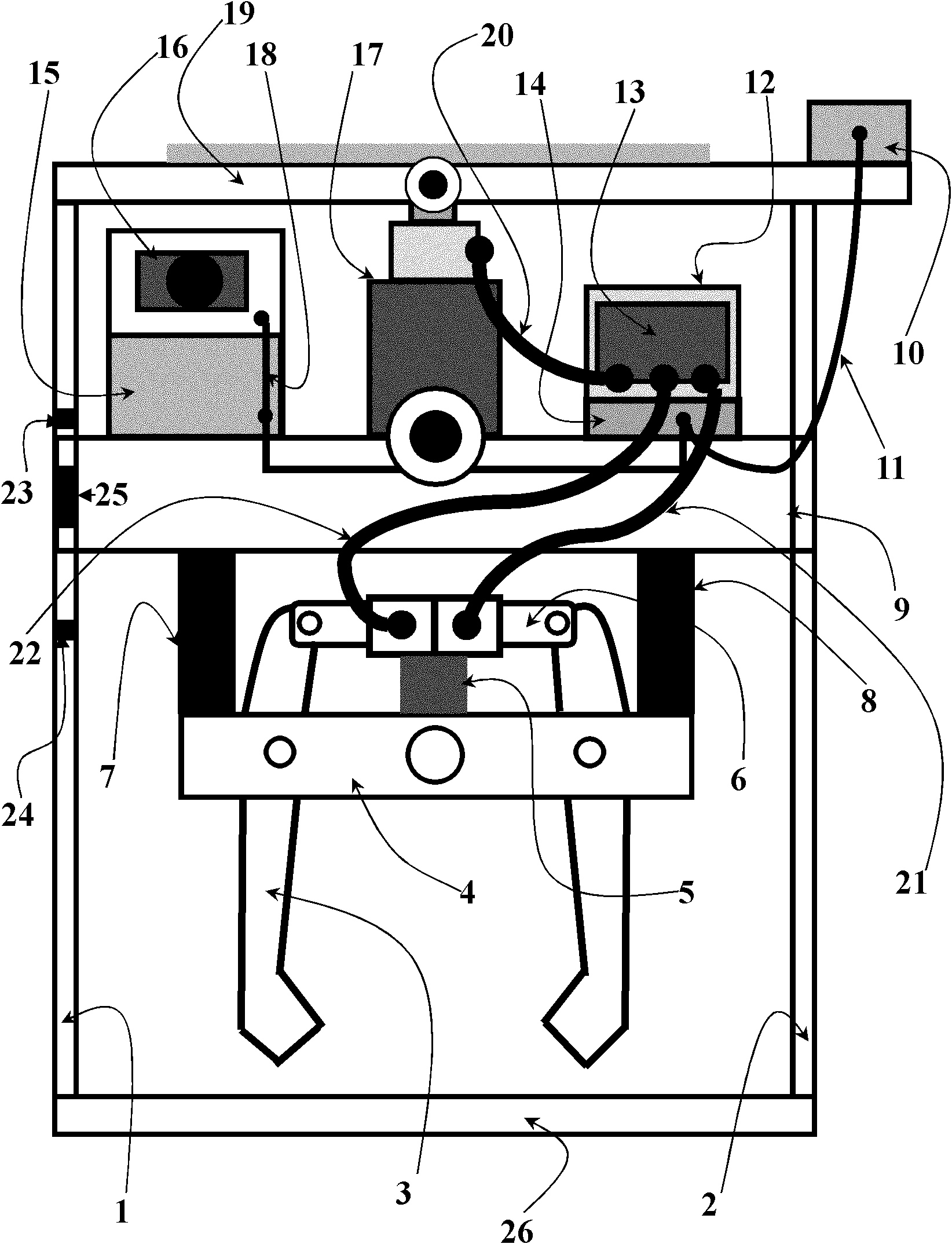

[0020] Attached below Figure 1-2 The small hydraulic automatic tamping machine and the intelligent control method of the present invention will be further described in detail.

[0021] like figure 1 Shown:

[0022] The small hydraulic automatic tamping machine consists of a first guide rail 1, a second guide rail 2, a pick body 3, a vibrating device 4, a first shock absorbing device 5, a hydraulic clamping mechanism 6, a second shock absorbing device 7, a third Shock absorbing device 8, lifting platform 9, intelligent operation platform 10, first signal line 11, pressurized oil pump 12, multi-way reversing solenoid valve 13, multi-way relay switch 14, power battery pack 15, high-power DC motor 16, Hydraulic lifting mechanism 17, second signal line 18, load beam 19, first hydraulic flexible shaft 20, second hydraulic flexible shaft 21, third hydraulic flexible shaft 22, upper Hall sensor 23, lower Hall sensor 24, magnetic element 25 and chassis 26 form. The first guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com