Equilateral triangle prismatic reinforcing bar section

A technology of equilateral triangles and triangular edges, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of small surface friction, steel gripping force and limited increase in anti-vibration ability, and achieve high friction , Improve the grip force, the effect of reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

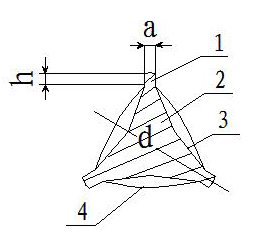

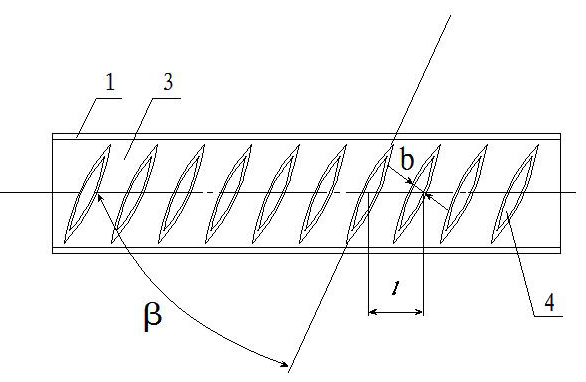

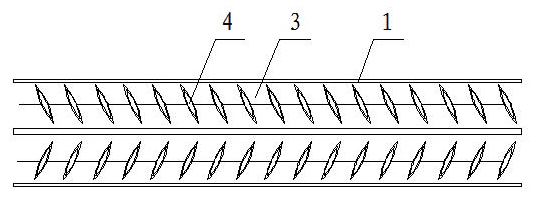

[0024] Such as figure 1 ——As shown in 4 and 9—12, an equilateral triangular prism-shaped steel bar profile is composed of inner base 2, transverse rib 4 and longitudinal rib 1, and its characteristics are: the section of inner base 2 is an equilateral triangular prism, Described equilateral triangular prism is a polygonal surface formed by each side concave of equilateral triangle, and its three sides are ∧-shaped sides, and three angles of equilateral triangular prism are connected with it as a whole. Square longitudinal rib 1, three ∧-shaped faces 3 of equilateral triangular prism are connected with it to have some crescent-shaped or ∧-shaped or angular or herringbone or twisted bar-shaped transverse ribs 4.

[0025] Such as Figure 5 ——As shown in 8, an equilateral triangular prism-shaped steel bar is composed of inner base 2, transverse rib 4 and longitudinal rib 1. It is characterized in that: the section of inner base 2 is an equilateral triangular prism, and The trian...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com