Method for controlling advancing mechanism

A technology for controllers and conveyors, which is applied in the direction of earth drilling, mining equipment, mine roof support, etc., and can solve problems such as inability to determine the angle, inability to control the inclination of the scraper, knocking down, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

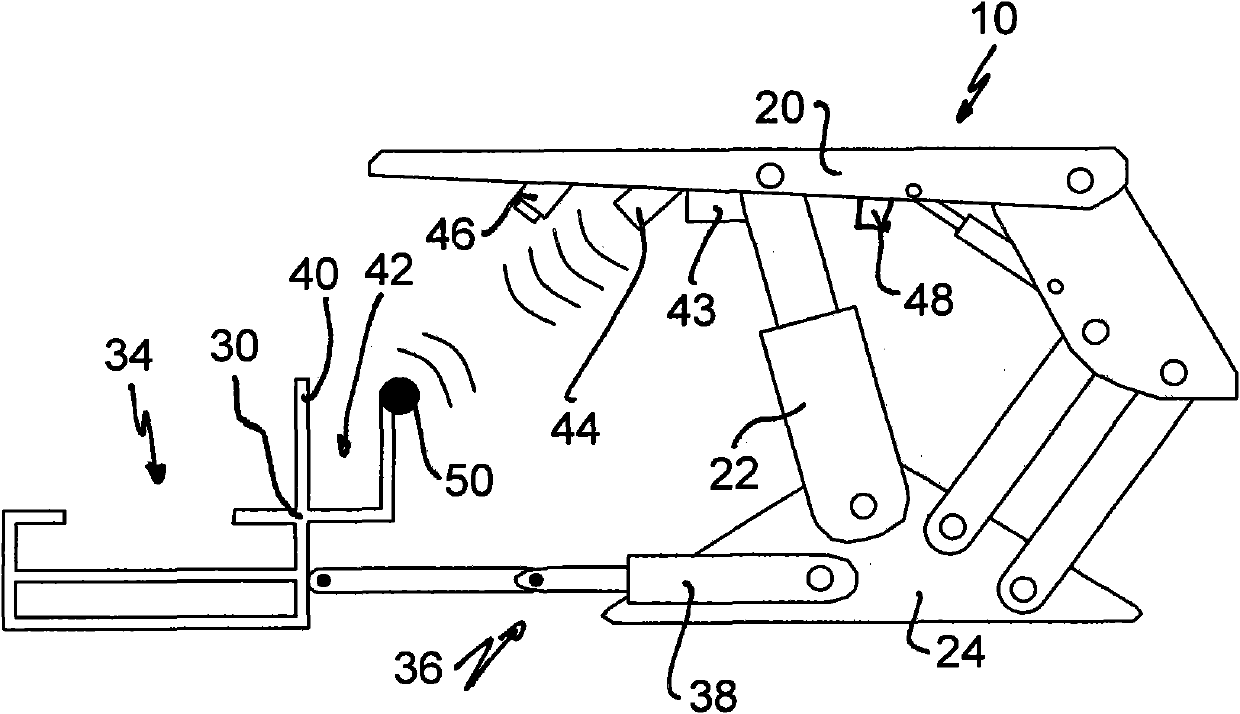

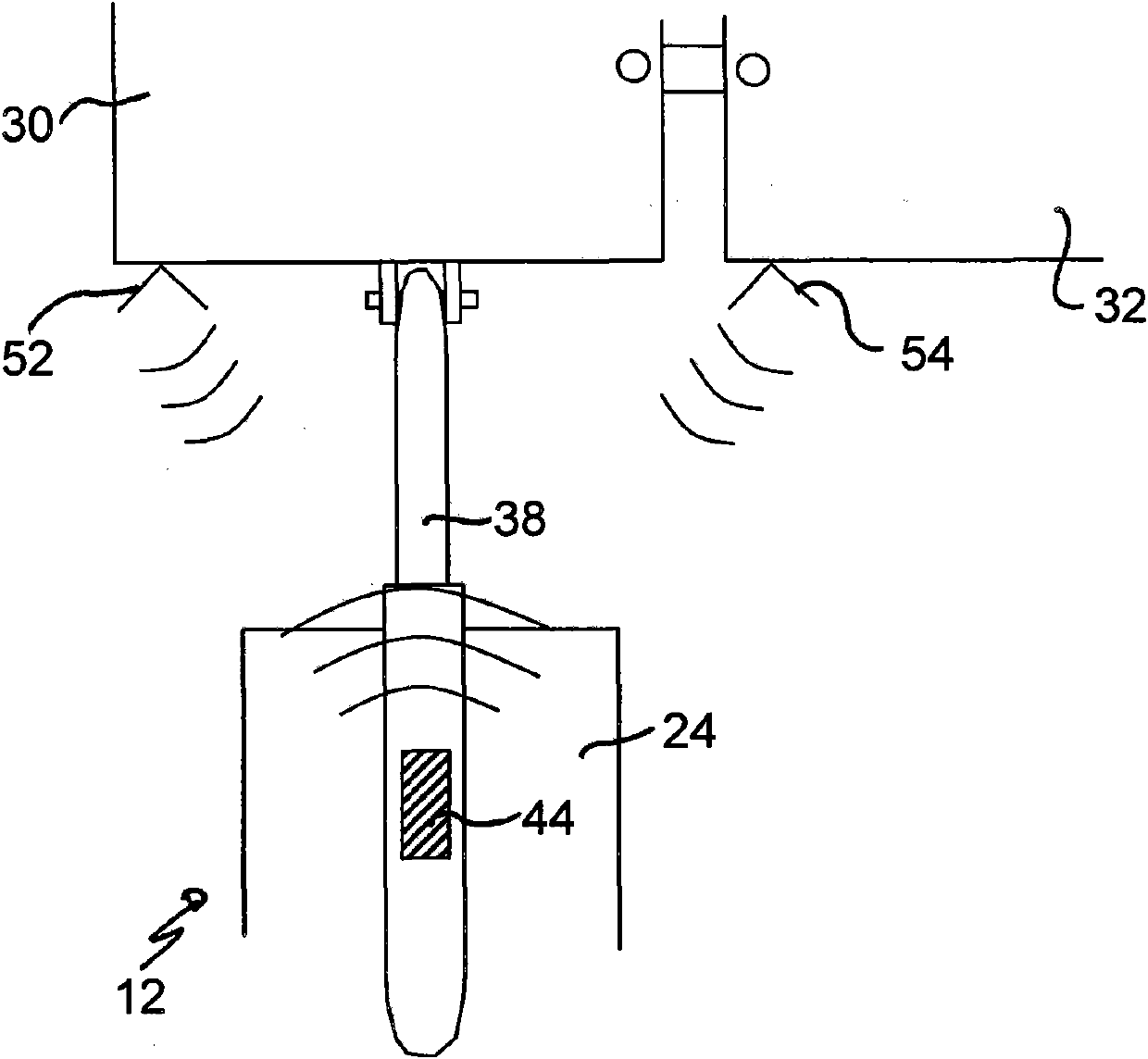

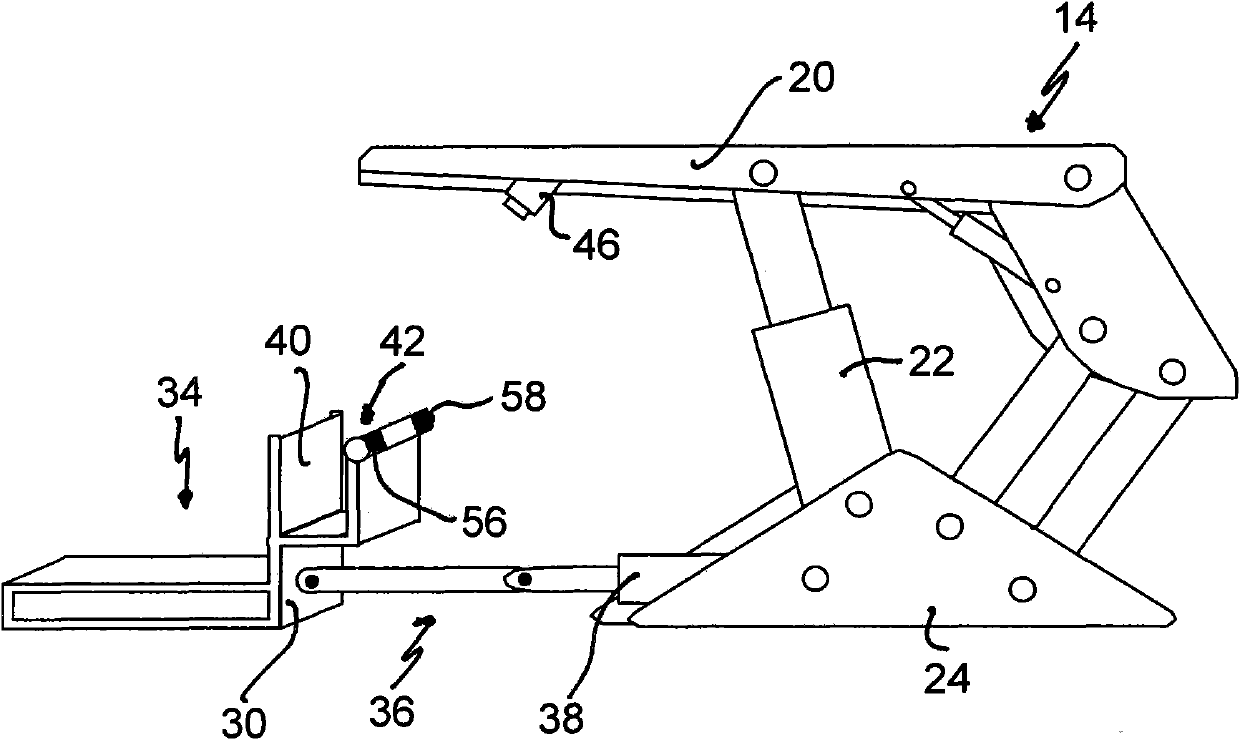

[0028] figure 1 A first embodiment of the shed-type combined support 10 is schematically shown, the top cover 20 of which is connected to the base 24 through the pillars 22 . By a plurality of scrapers 30,32 (see figure 2 ) Conveyor 34 of composition is connected with shed type combination support 10 in a known manner by stepping mechanism 36, and wherein stepping mechanism has moving jack 38. Each scraper 30 , 32 of the conveyor 34 has a vertical stop 40 on the side facing the shed combination 10 , on the back of which a cable and line channel 42 is connected.

[0029] In addition, the shed combination support 10 is equipped with an electrohydraulic controller 43 in a known manner, which is arranged between the pillars 22 on the underside of the roof 20, and which and the central working surface controller (not shown) out) connected. Furthermore, an ultrasonic sensor 44 and a camera 46 are located on the underside of the roof 20 , the ultrasonic sensor 44 being arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com