Torque overload protection device

A technology of overload protection and transmission, applied in the direction of couplings with safety disconnection joints, couplings, mechanical equipment, etc., can solve the problems of low control accuracy, poor versatility, and heavy maintenance workload of spare parts, etc. Achieve the effect of reducing production management costs and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

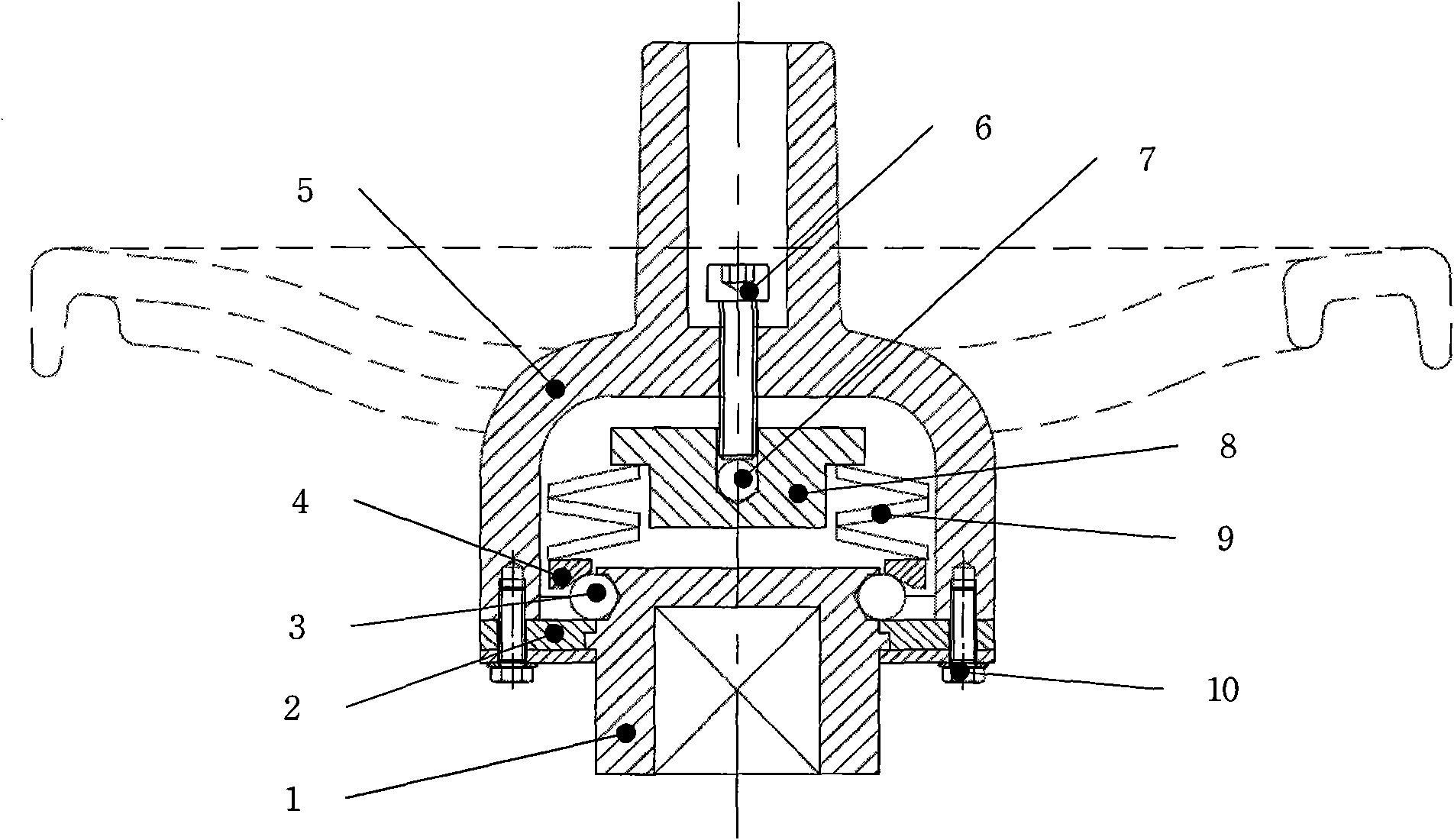

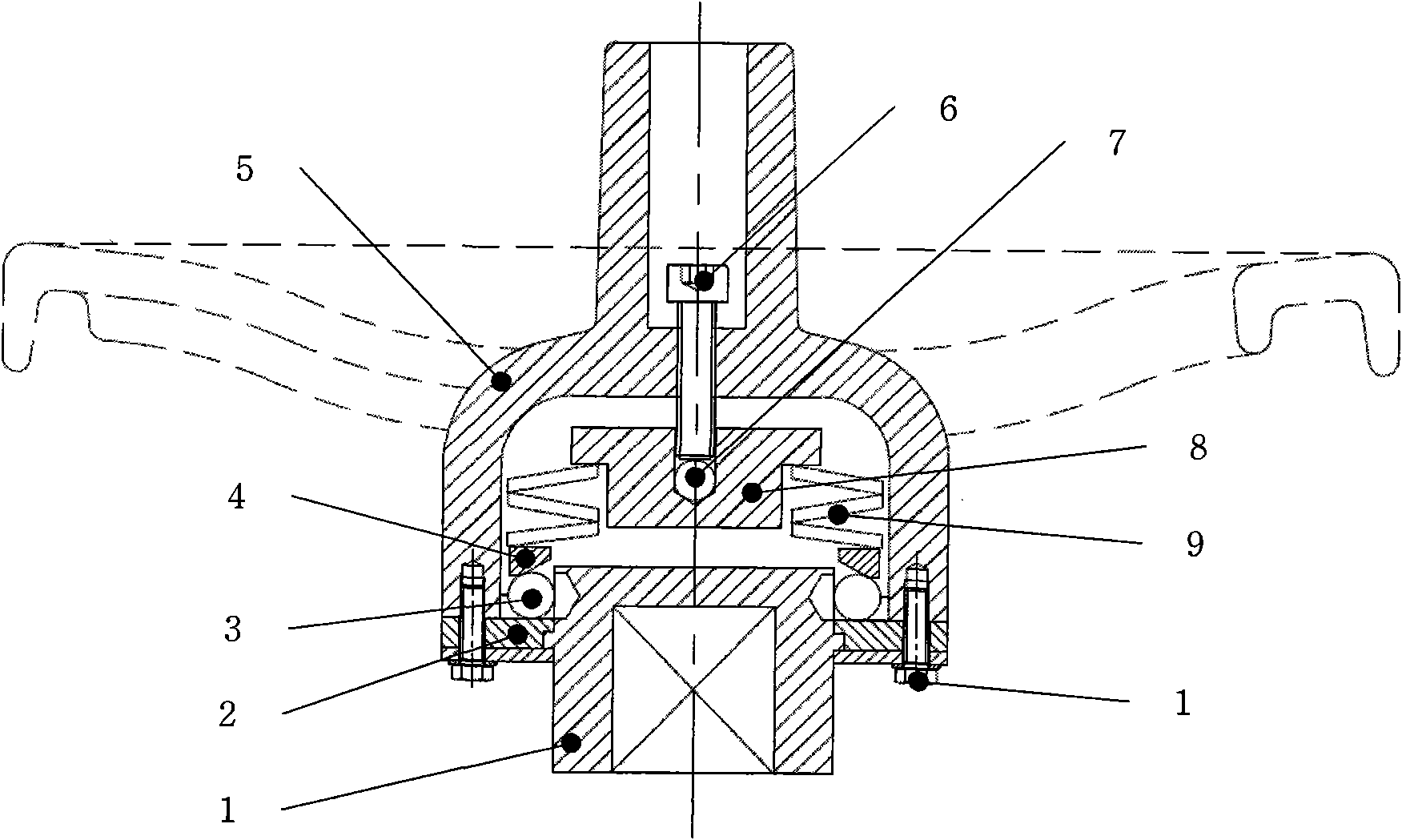

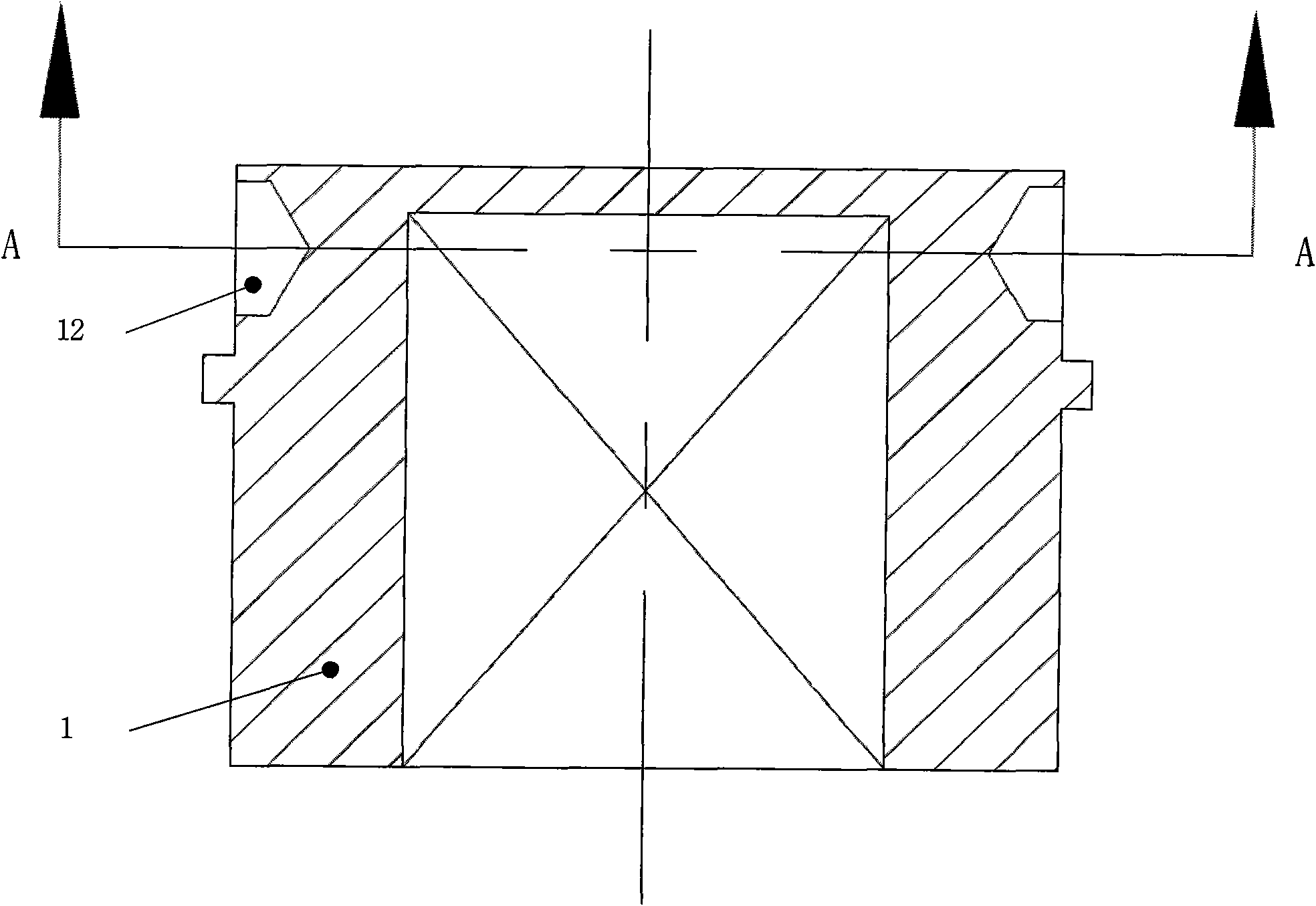

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a torque overload protection device includes a transmission head 1, a transmission seat 2, a transmission ball 3, a pressure ring 4, a transmission device 5, an adjustment screw 6, an adjustment ball 7, an adjustment block 8, a butterfly spring group 9, Fix the bolt 10. The transmission device 5 may be a transmission cap, or other driving equipment such as a hand wheel. The transmission head 1 is cylindrical, the middle hole matches the valve stem, a plurality of transmission holes 12 are evenly distributed on the top of the outer circle, the bottom of the transmission holes 12 is a tapered surface, and the middle part of the outer circle is a limiting flange. The transmission seat 2 is disc-shaped, with a plurality of bolt holes distributed on the circumference, the middle hole is matched with the outer circle of the transmission head 1, and a plurality of transmission grooves 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com