Illuminating beam shaping system

A technology of lighting beams and beams, applied in lighting devices, lighting and heating equipment, components of lighting devices, etc., can solve the problems of weakening and reducing the working effect, and achieve the effect of avoiding refraction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

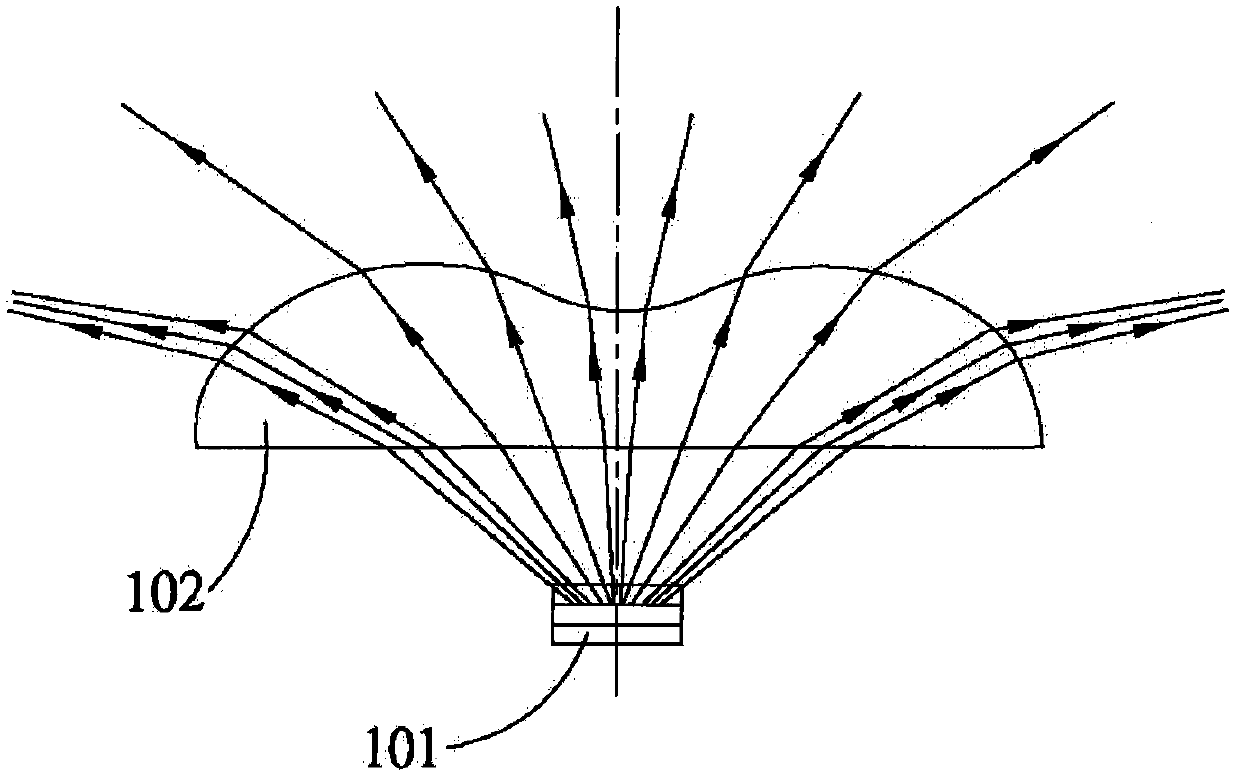

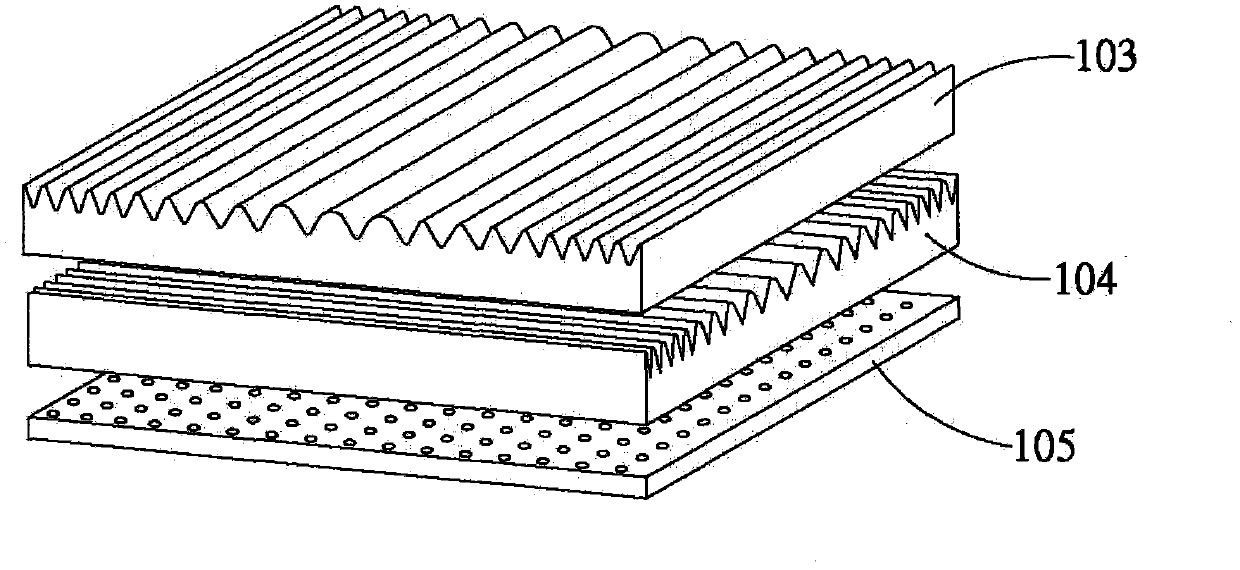

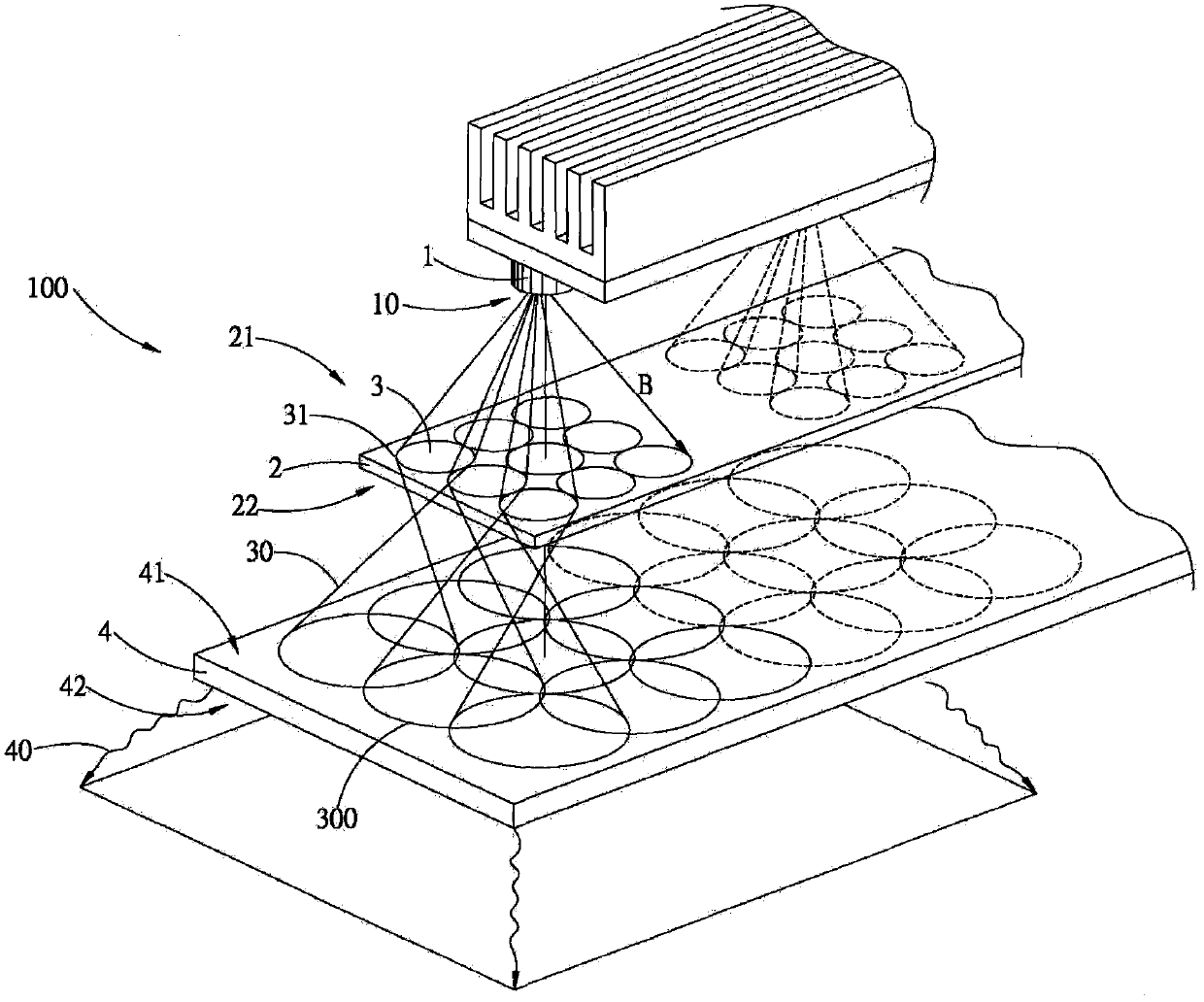

[0032] The beam shaping system of the present invention is especially used for similar laser chips, the total light quantity of which is divided into a plurality of groups of conical beams through the pre-segmentation means, and the actual optical surface of the bottom of the cone beams acts synchronously on an optical diffusion After the component is refracted and diffused by the optical diffusion component, a more uniform illumination brightness can be obtained on the light-emitting surface of the system. In the implementation description of this formula, the oblique reflection of the lens or spherical aberration is not considered, and it will be explained first.

[0033]The present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this description, the principle of the present invention will be described through embodiments. Other aspects, features and advantages of the present invention will become clear at a glance throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com