Contact type image sensor

An image sensor, contact technology, applied in image communication, instruments, electrical components, etc., can solve the problems of large number of ultraviolet LEDs, unacceptable mass production, poor uniformity, etc., to achieve low cost, solve serious attenuation phenomenon, and ensure uniformity Effects of Sex and Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

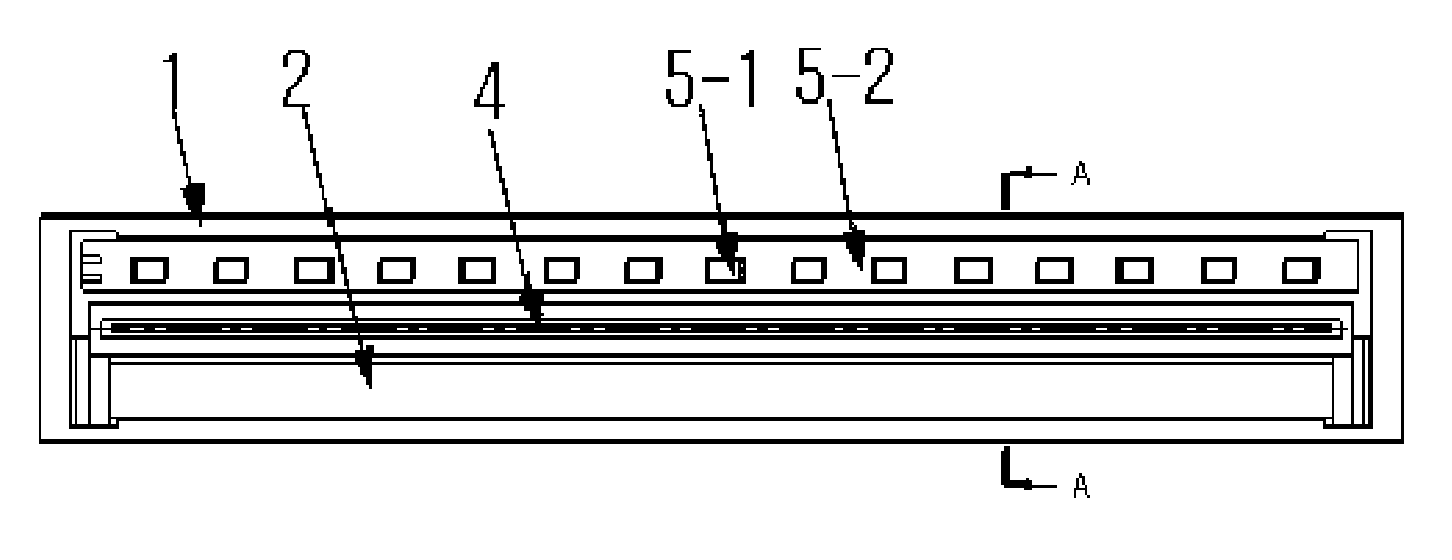

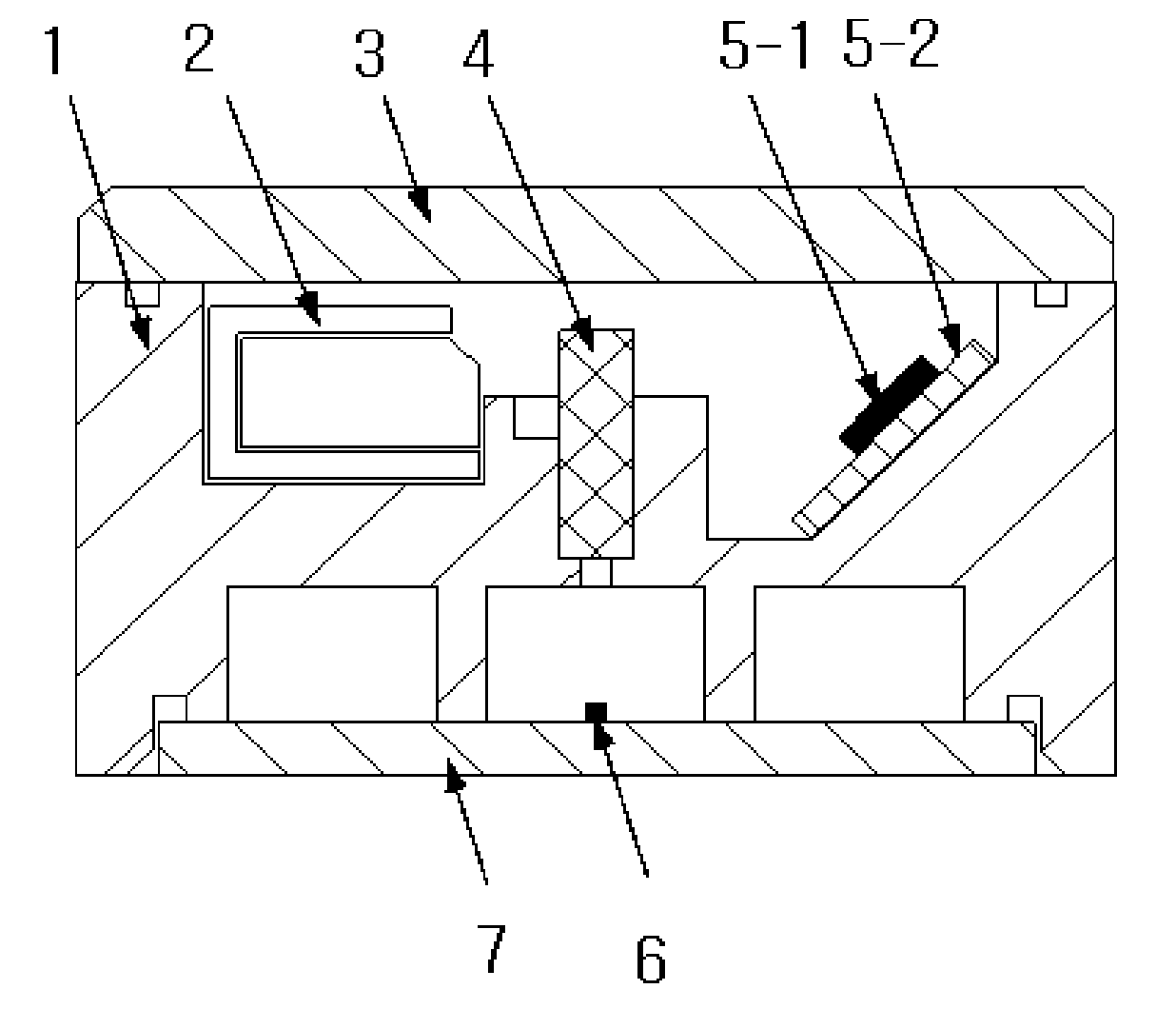

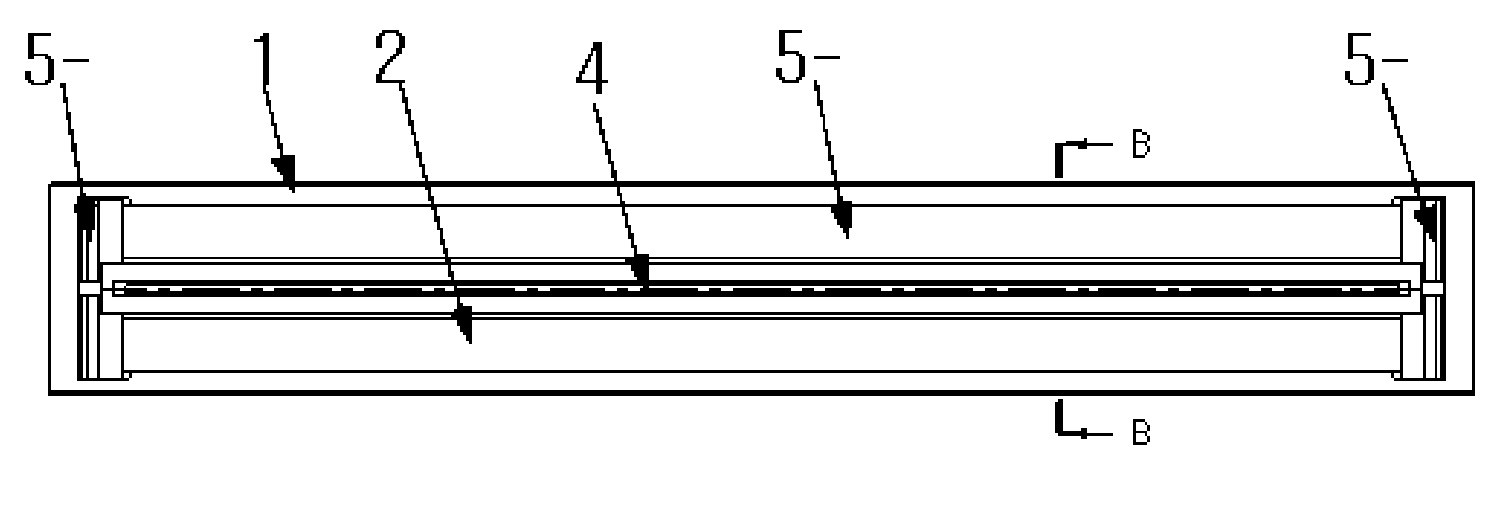

[0017] Such as image 3 , Figure 4 As shown, a contact image sensor is provided with a frame 1, a circuit board 7 is provided under the frame 1, a photoelectric conversion chip 6 is provided on the circuit board 7, a lens 4 is installed above the photoelectric conversion chip 6, and a lens 4 is provided on the side of the lens 4. Light source 2, the top of frame 1 is provided with glass plate 3, above-mentioned is the same as prior art, belongs to those skilled in the art should know, this does not go into details, the feature of the present invention is that lens 4 side is provided with by ultraviolet LED5-1, LED circuit An ultraviolet light source composed of plate 5-2, light guide body 5-3 and metal light guide plate 5-4, ultraviolet LED5-1 is located at the end of light guide body 5-3, light guide body 5-3 of the present invention can be one end Ultraviolet LEDs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com