Tailor welding method of thick aluminium alloy plate

An aluminum alloy plate, aluminum plate technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the requirements of X-ray flaw detection level II weld, high cost of electron beam welding, low tensile strength, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0027] Use molten electrode argon arc welding, the specific implementation steps are as follows:

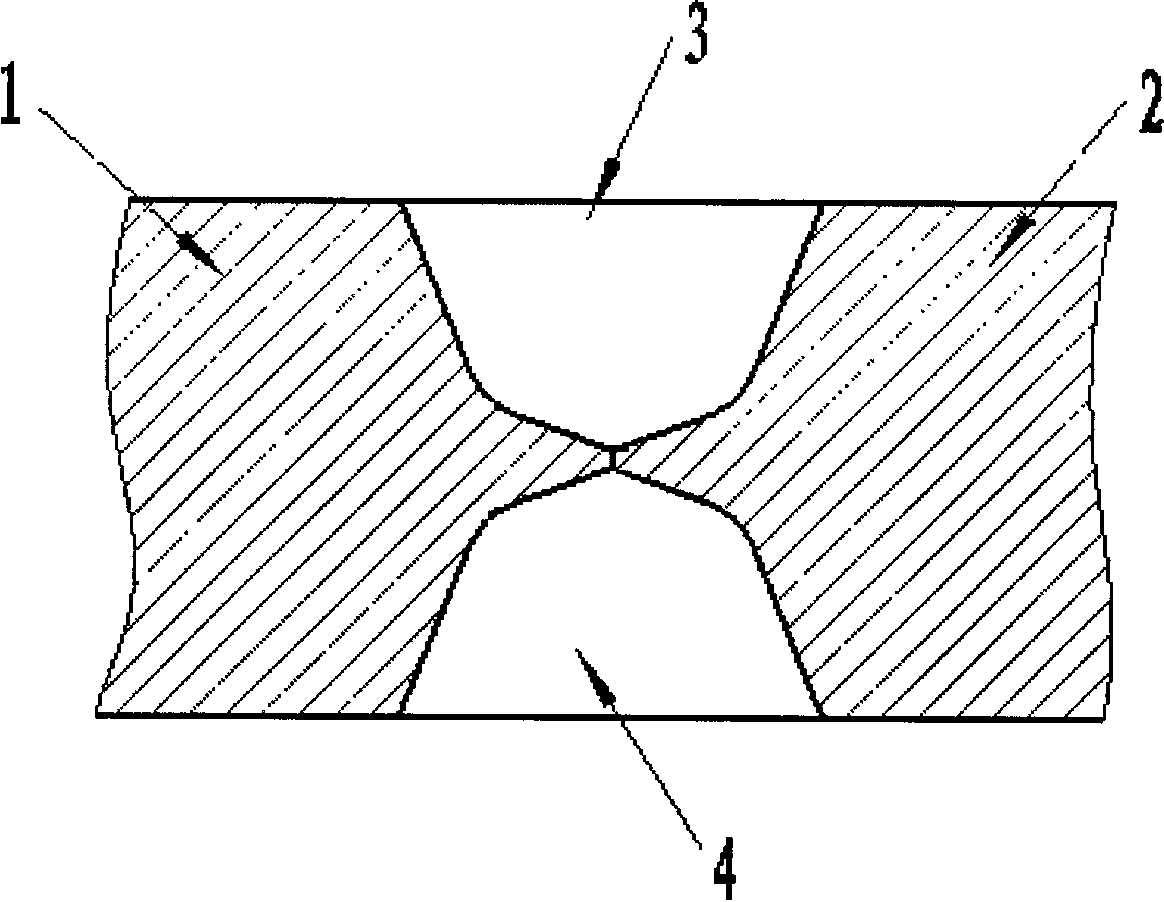

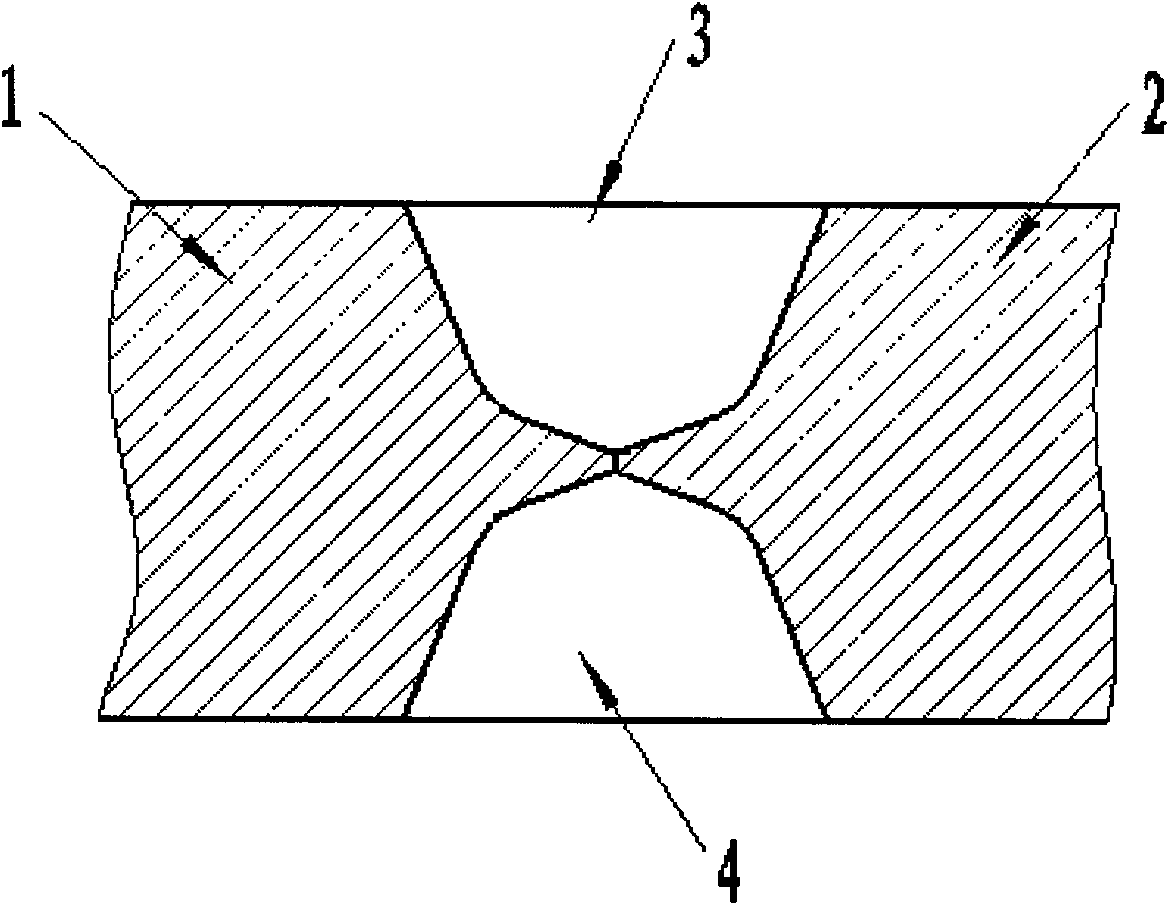

[0028] (1) The two tailor-welded aluminum sheets 1 and 2 are grooved 3 respectively, and the welded groove 3 is mechanically cleaned to remove the oxide film and other impurities on the groove;

[0029] (2) Aluminum alloy plates 1 and 2 are preheated, and the preheating temperature is kept in the range of 70°C to 150°C, that is, 70°C, 75°C, 80°C, 85°C, 90°C, 95°C, 100°C, 105°C, 110°C, 115°C, 120°C, 125°C, 130°C, 135°C, 140°C, 145°C, 150°C, and keep the ambient temperature at 13°C~26°C, the ambient temperature is 13°C, 16°C, 19.5°C , 23°C, 26°C, ambient humidity less than 50%;

[0030] (3) Seam two tailor-welded aluminum alloy plates 1 and 2, keep the gap between the two plates at 0mm to 5mm, and the gap between the two plates is 0mm, 1mm, 2mm, 3mm, 4mm or 5mm;

[0031] (4) Carry out back welding: first weld one section to the center, then weld two sections on both sides, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com