Pointed double-sided cutter for machine tool cutting

A double-edged, pointed technology, applied in decorative arts, engraving, etc., can solve the problems of low work efficiency, inability to enlarge the cutter head, short service life, etc., to achieve long service life, avoid high cost, knife marks Chiseled smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

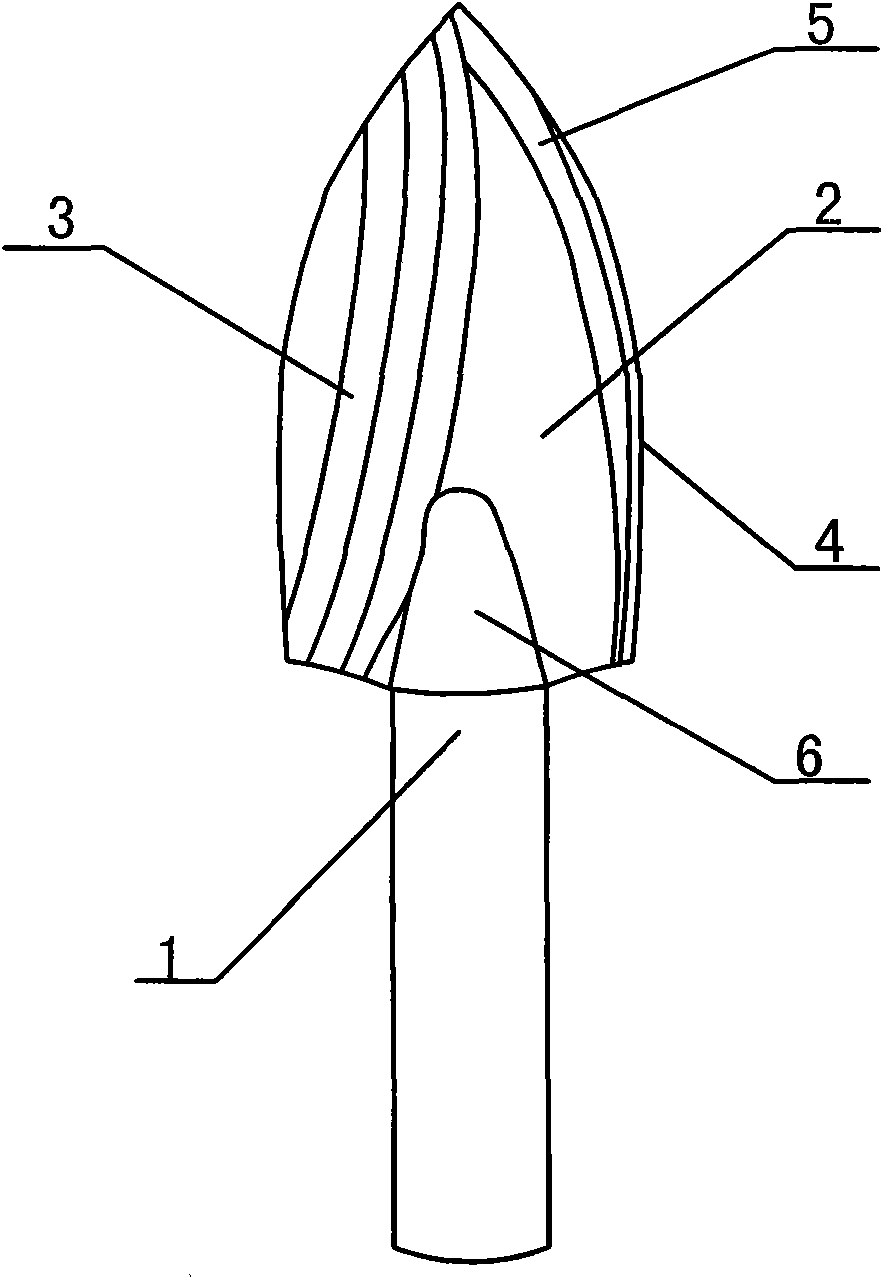

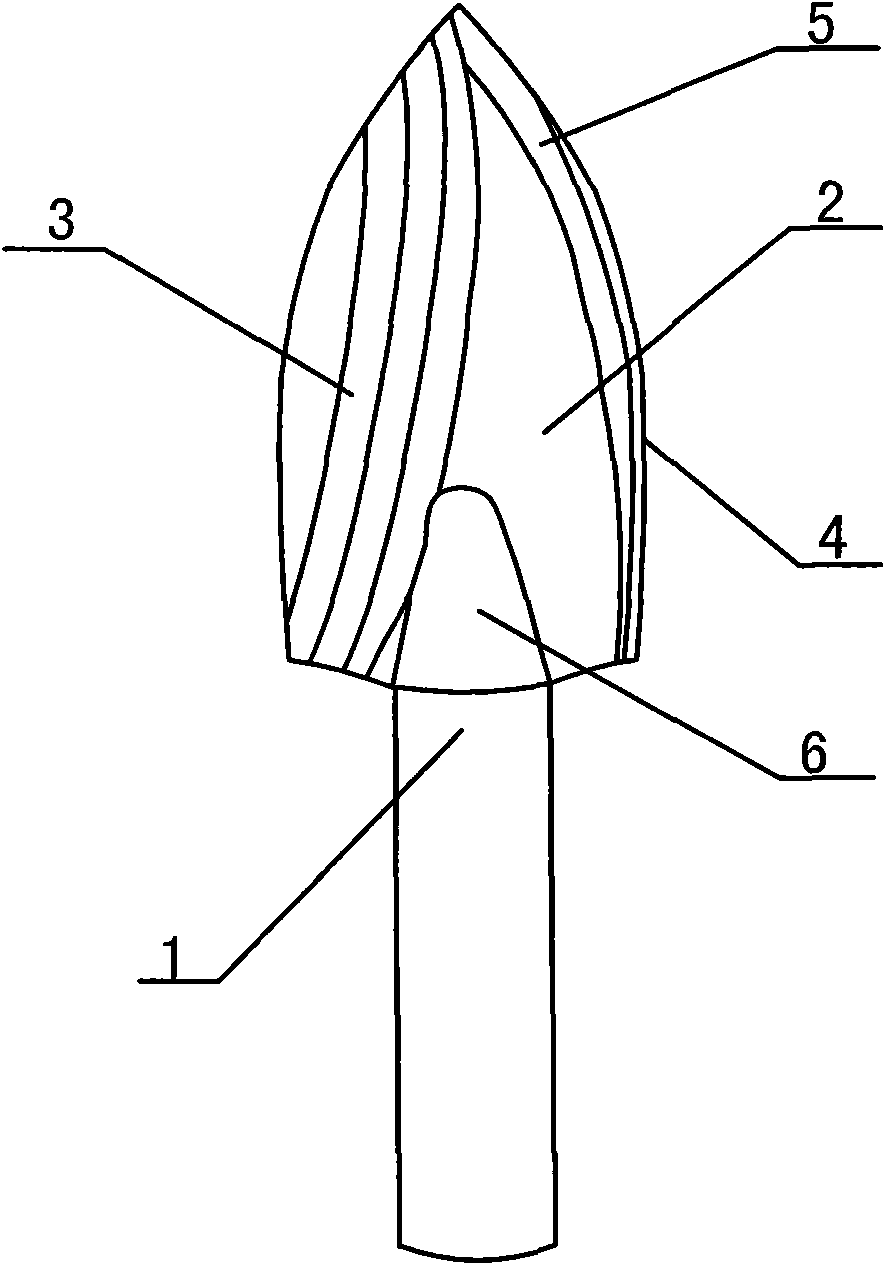

[0011] Such as figure 1 As shown, the pointed double-sided cutting tool for machine tool cutting according to the embodiment of the present invention includes a cutter shaft 1, a pointed cutter head 2, a blade 4 and a welded body 6, and the whole cutter head made of white steel is flat, The structure of the front of the pointed cutter head 2 is consistent with the reverse side, and the outer edge of the knife edge 3 on the left side is provided with a blade 4, and the surface of the knife edge 3 is sunken in the upper surface of the pointed cutter head 2, and the right side of the pointed cutter head 2 A knife edge 4 is provided at the ridge 5 , thereby forming a double-sided arc-shaped knife head; the pointed knife head 2 and the knife shaft 1 are welded together through a welding body 6 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap