Yarn winding device

A technology for winding machines and yarns, applied in the field of yarn winding machines, can solve the problems of breakage, easy contact with push-out parts, and reduced package quality, and achieve the effects of preventing breakage, preventing interference, and preventing quality reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

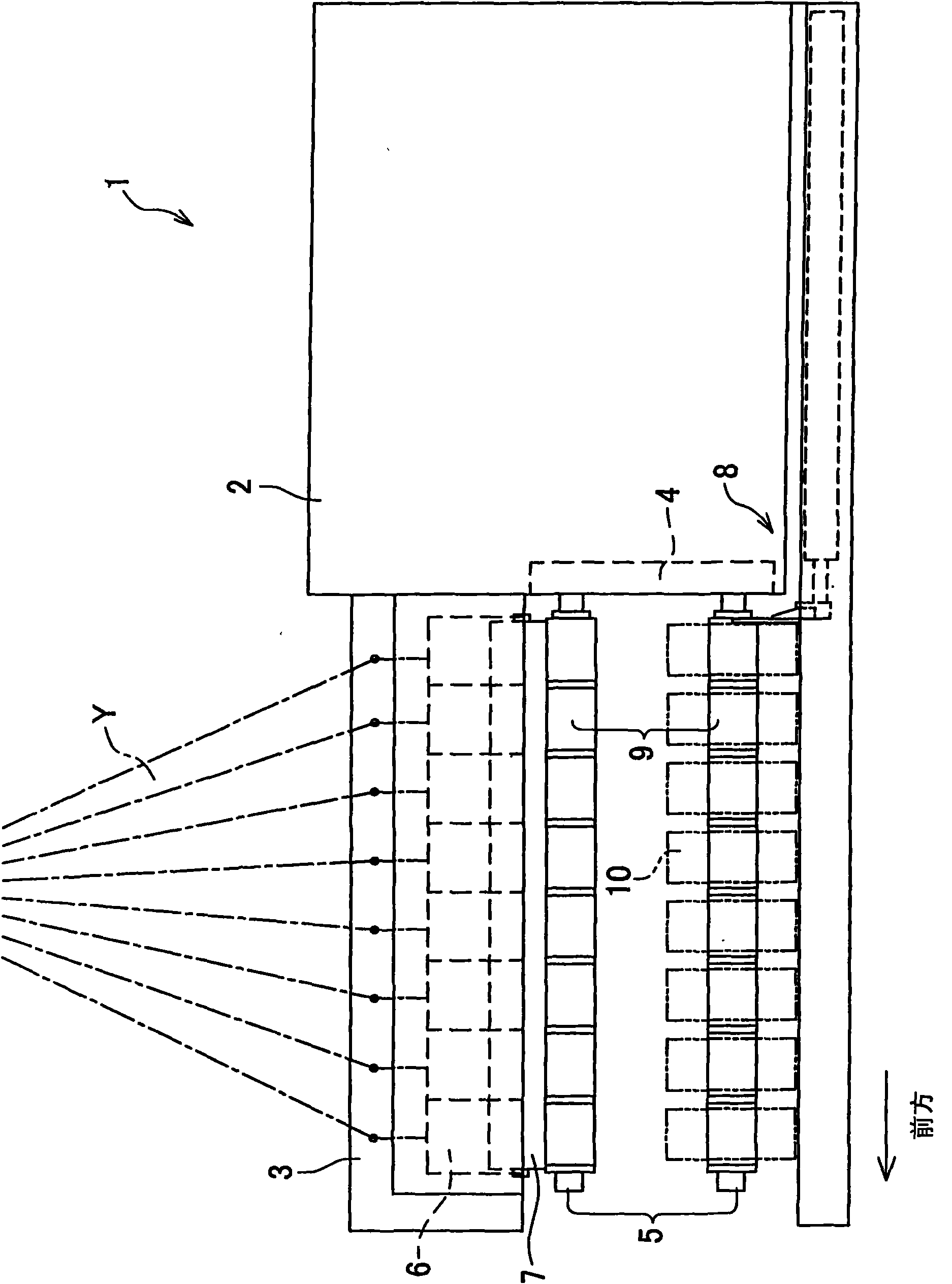

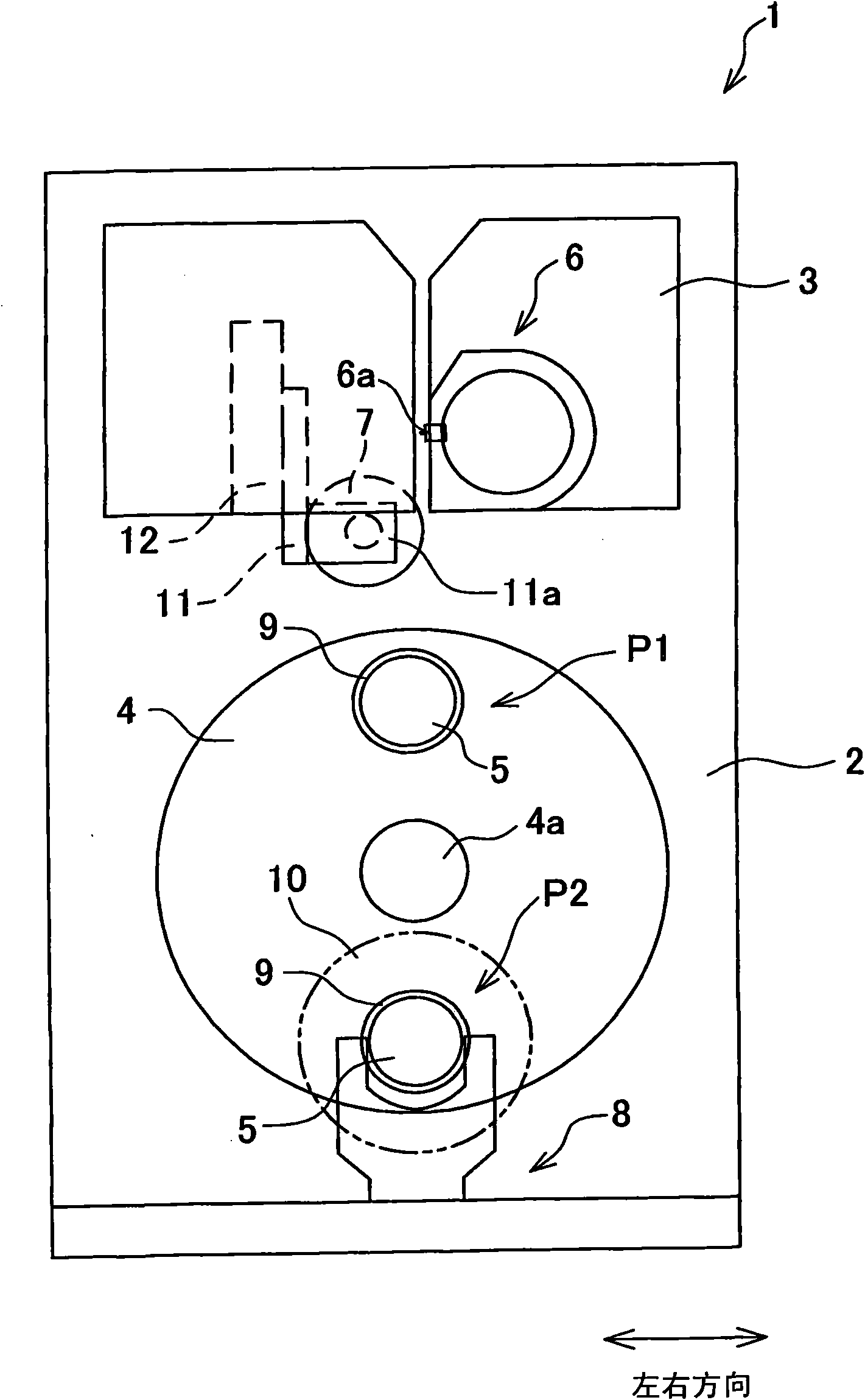

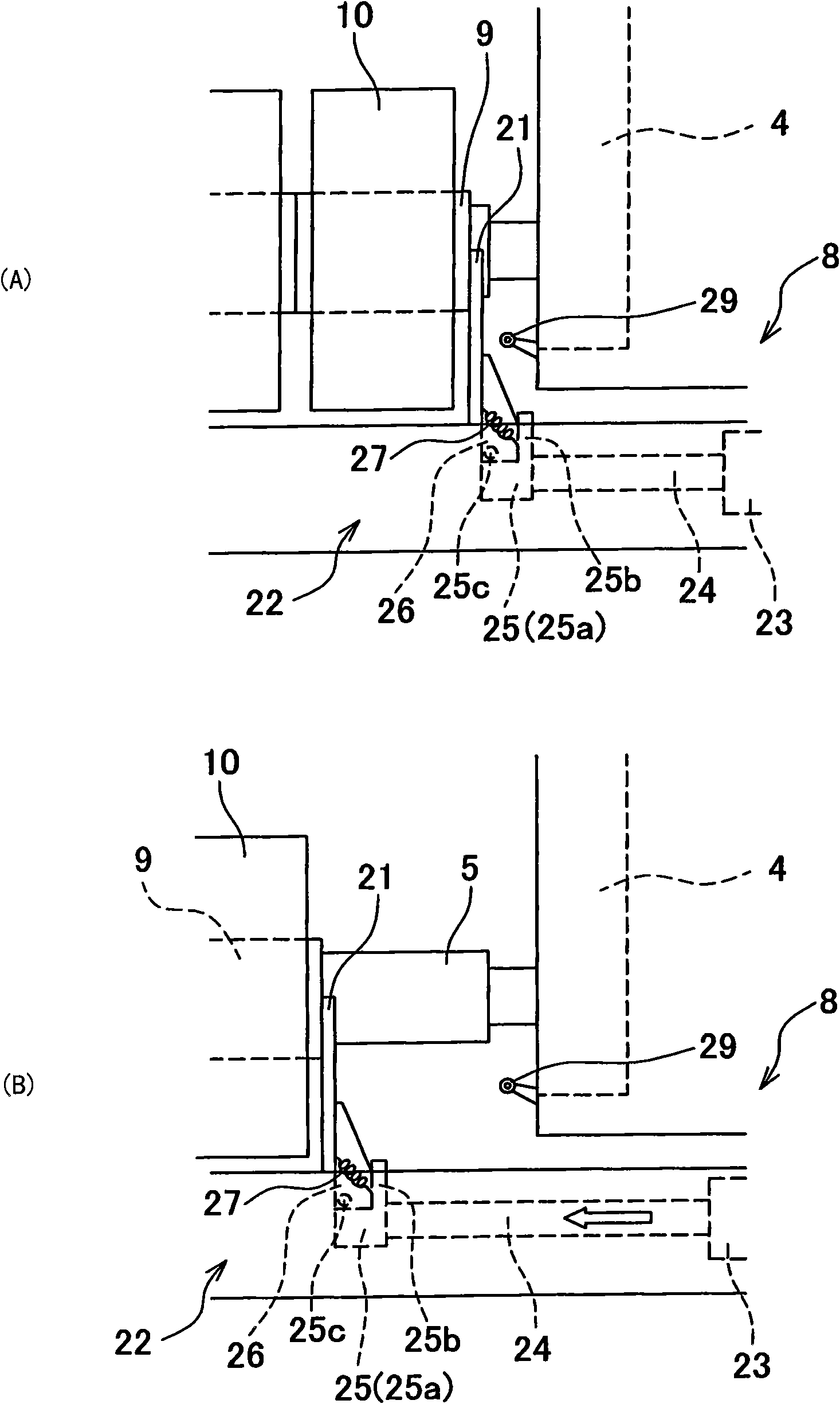

[0019] Next, embodiments of the present invention will be described. figure 1 It is a side view of the yarn winding machine according to one embodiment of the present invention. figure 2 It is the front view of the yarn winding machine. Such as figure 1 As shown, a plurality of yarns Y are continuously supplied to the yarn winding machine 1 from a spinning machine (not shown). In addition, the yarn winding machine 1 is configured to wind a plurality of yarns Y supplied from a spinning machine on a plurality of bobbins 9 to form a plurality of packages 10, and the plurality of packages 10 are removed by the pusher 8. .

[0020] Such as figure 1 and figure 2 As shown, the yarn winding machine 1 includes a main body support 2, an elevating frame 3 provided on the main body support 2 so as to be movable (up and down) in the vertical direction, and a disc-shaped turntable rotatably provided on the main body support 2. 4. One end is supported by the turntable 4 and is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com