Digital generator device

A digital generator and engine technology, applied in engine components, machines/engines, engine cooling, etc., can solve the problems of unbalanced temperature of the whole machine, reduce heat generation, high cost, etc., to improve overall performance and reliability, The effect of lowering the overall temperature and lowering the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

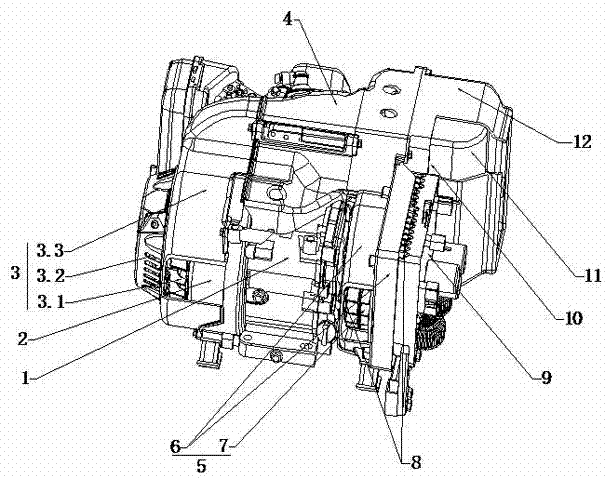

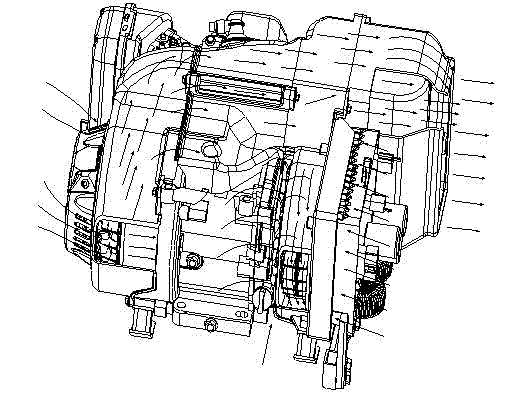

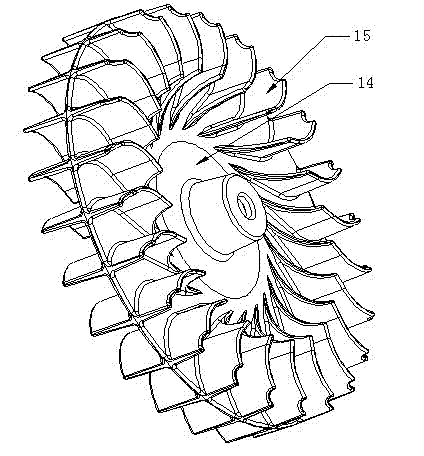

[0018] like figure 1 , 2 As shown, a digital generator device includes: an engine 1 with a shock absorbing device and a generator 2 coaxially arranged with the engine crankshaft and driven by the engine (from the direction shown in the figure, the engine 1 is located in the entire The middle part of the device, the generator 2 is located on the left side of the engine 1); the inverter 9 on the side of the cooling fan 5 on the right side of the engine 1 (as seen from the figure, the inverter 9 is arranged on the far right of the entire device), The inverter 9 corresponds to the air inlet 8 of the cooling fan 5; the rotor of the generator 2 is provided with an impeller 3.1 coaxial with the crankshaft of the engine 1, and a windshield 3.3, which is provided with an air inlet 3.2, Simultaneously at the outlet position of wind cover 3.3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com