Sand removing equipment

A kind of equipment and technology of sand settling tank, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of continuous sand removal treatment, complex structure, closed working environment, etc. Simple, easy to monitor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

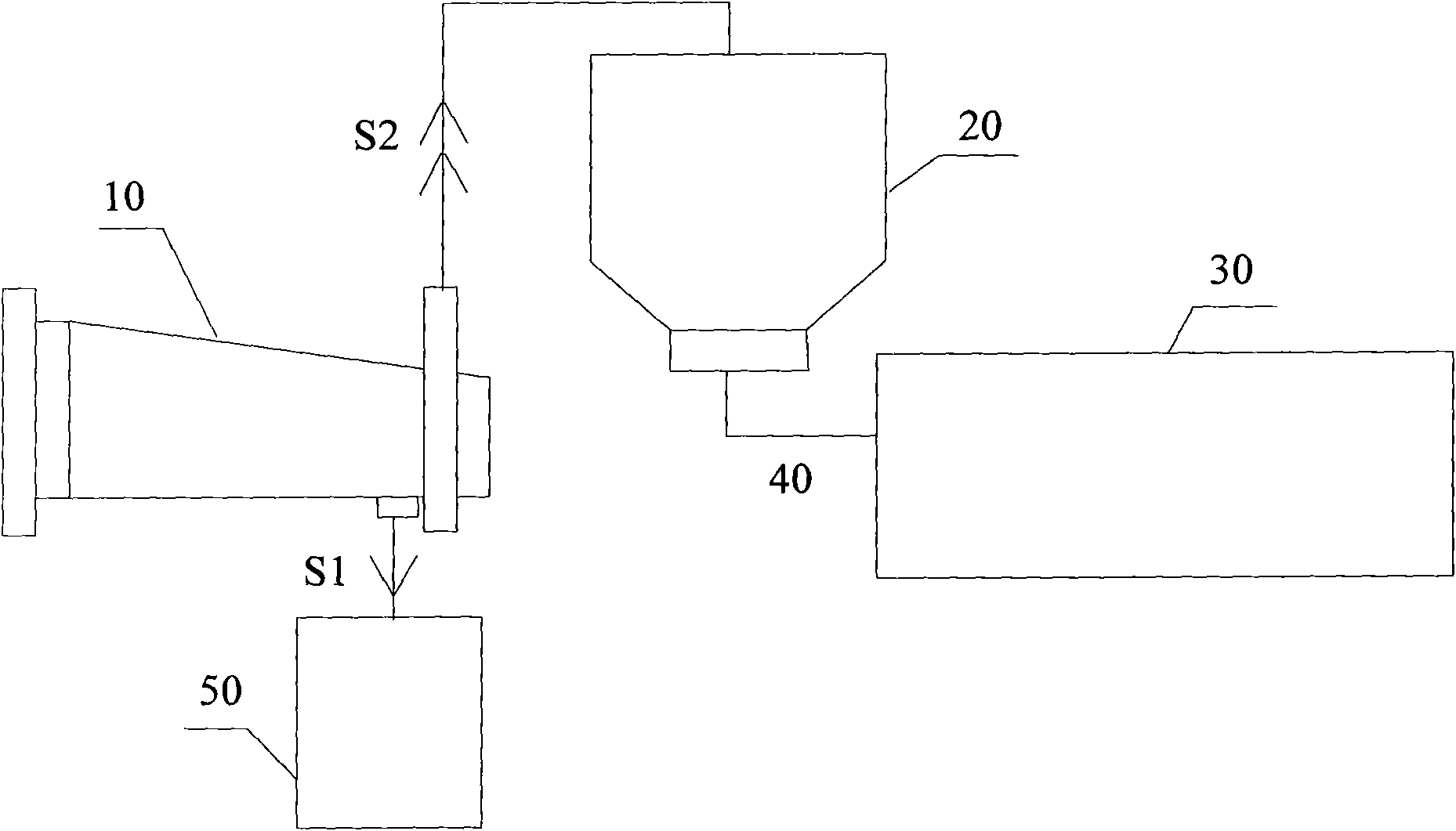

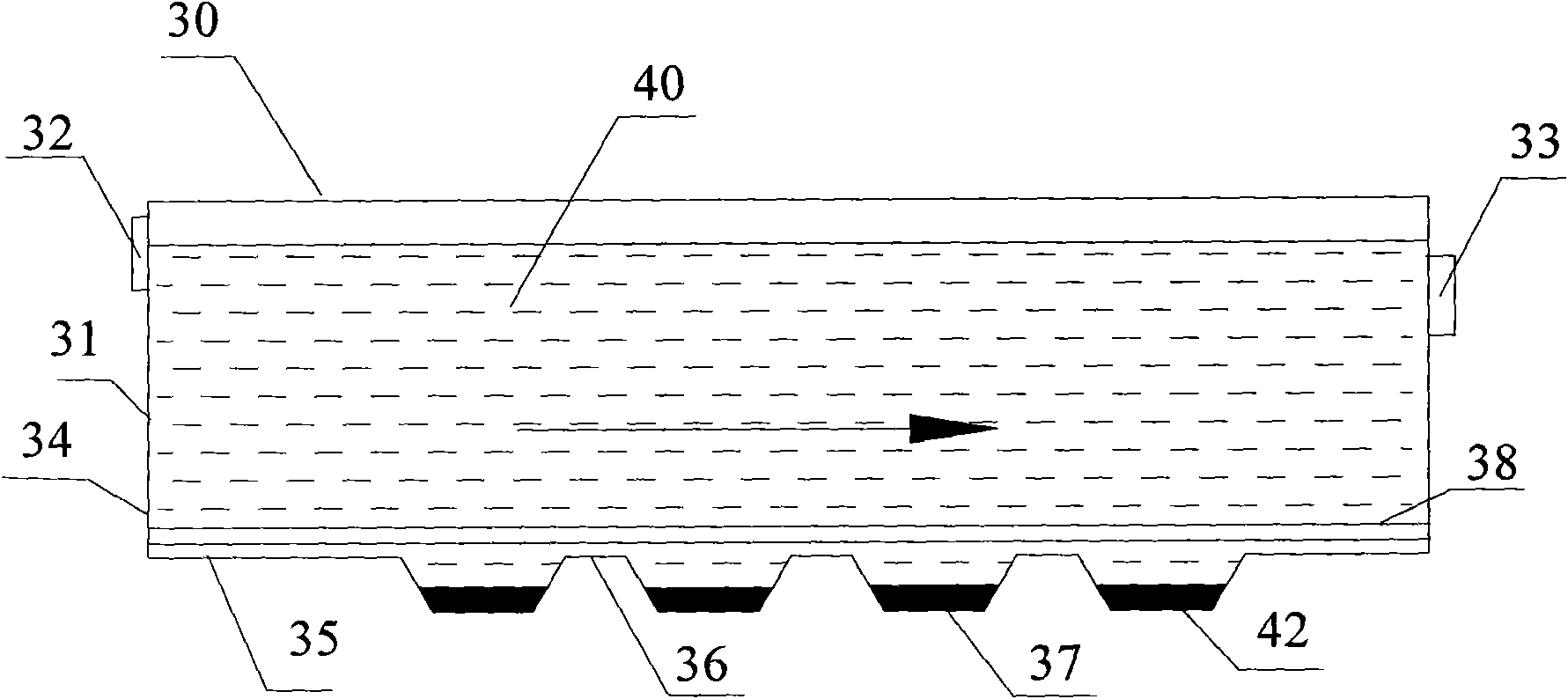

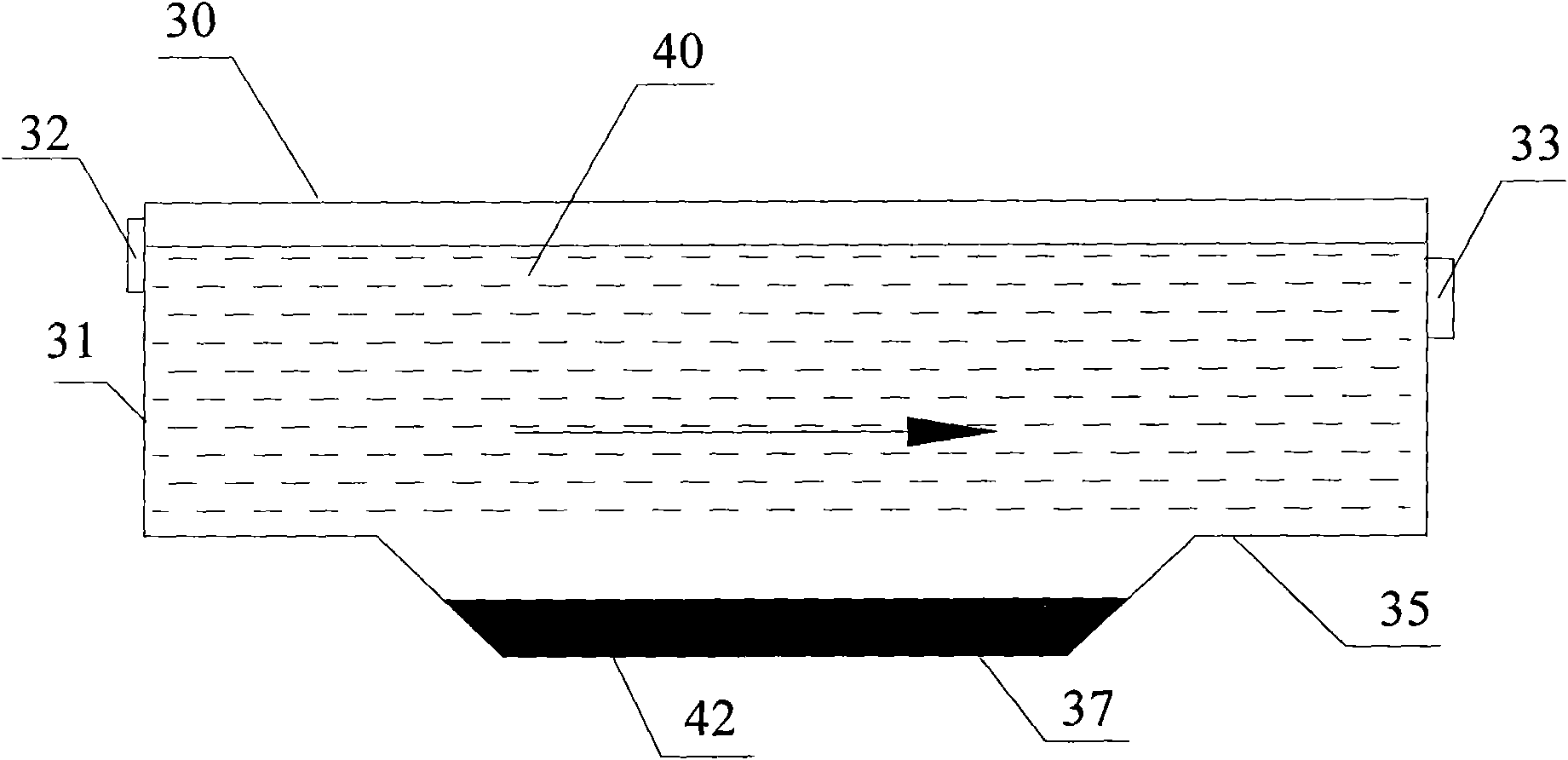

[0011] like figure 1 As shown, the sand removal device of the present invention includes a particle classification device 10, an aggregate device 20 and a sand settling tank 30 connected in sequence.

[0012] The sand removal equipment provided by the present invention can be used to separate various systems that need to separate one of the solid particles, as long as the density of one of the solid particles is greater than that of the other solid particles and is insoluble in a solvent. When the sand removal equipment provided by the present invention is used for separating one of the solid particles with a density greater than that of the other solid particle, both solid particles are insoluble or slightly soluble in the solvent, and the density of the two solid particles is greater than The advantages of the present invention are particularly manifested when the density of the solvent is concerned. A solid particle mentioned here refers to solid particles of various shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com