Transfer film having stereo matt pattern and manufacturing method thereof

A manufacturing method and transfer film technology, which are applied in the fields of technology and decorative art for producing decorative surface effects, and can solve the problems of incomplete functional application of transfer film and unsatisfactory application structure design of transfer film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

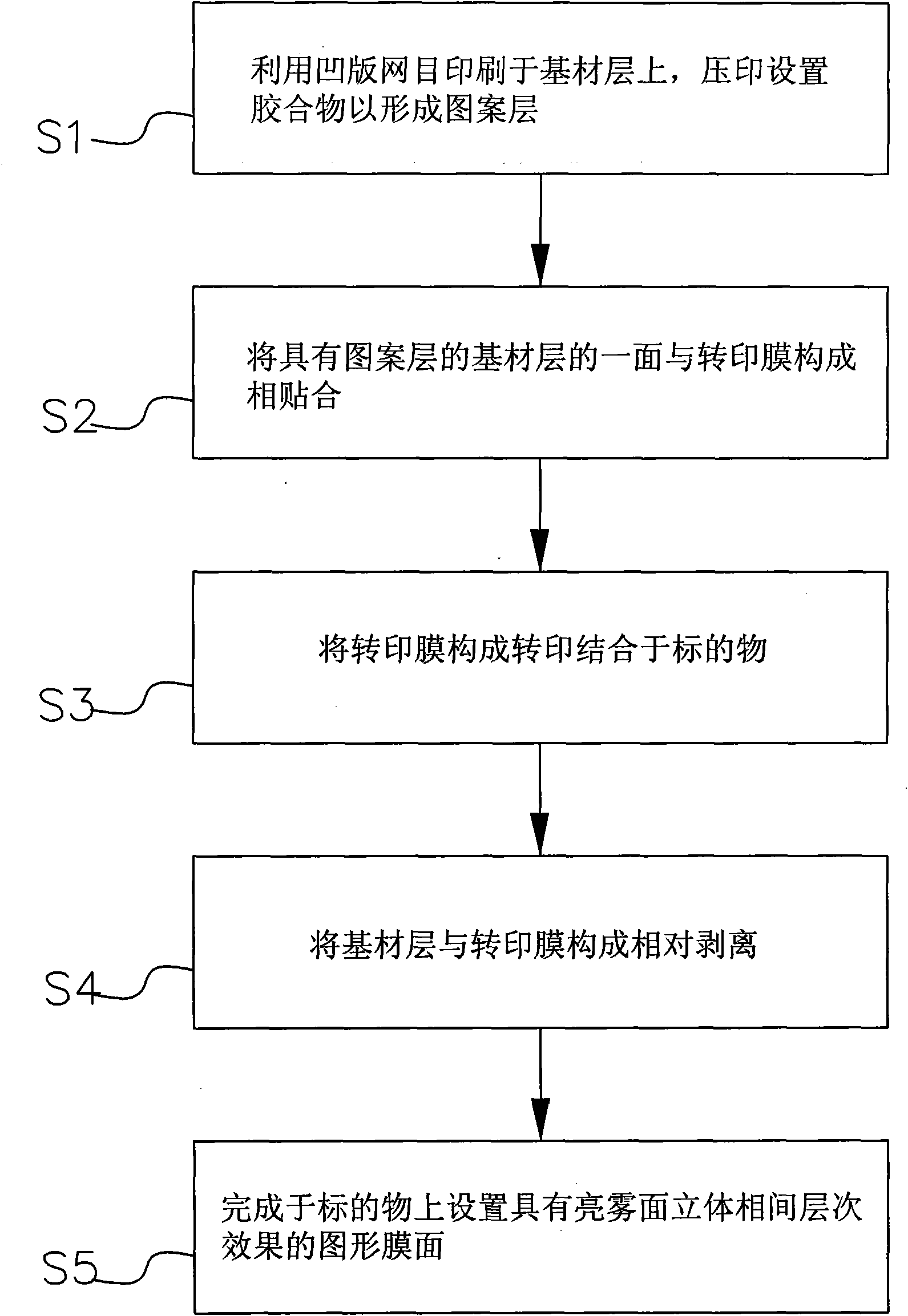

[0029] In order to obtain a further understanding and understanding of the technical features and the achieved effects of the present invention, a preferred embodiment and accompanying drawings are now described in detail as follows:

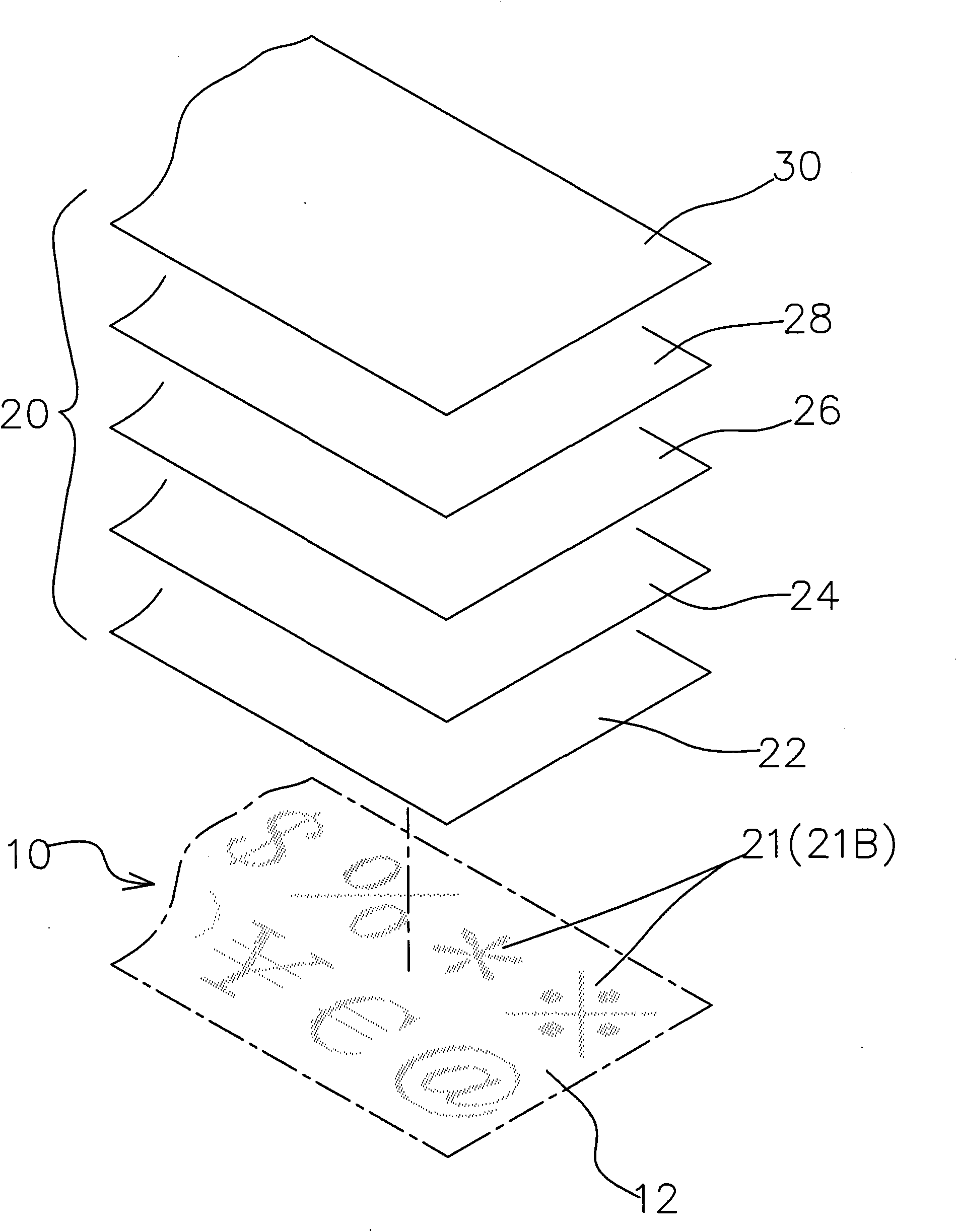

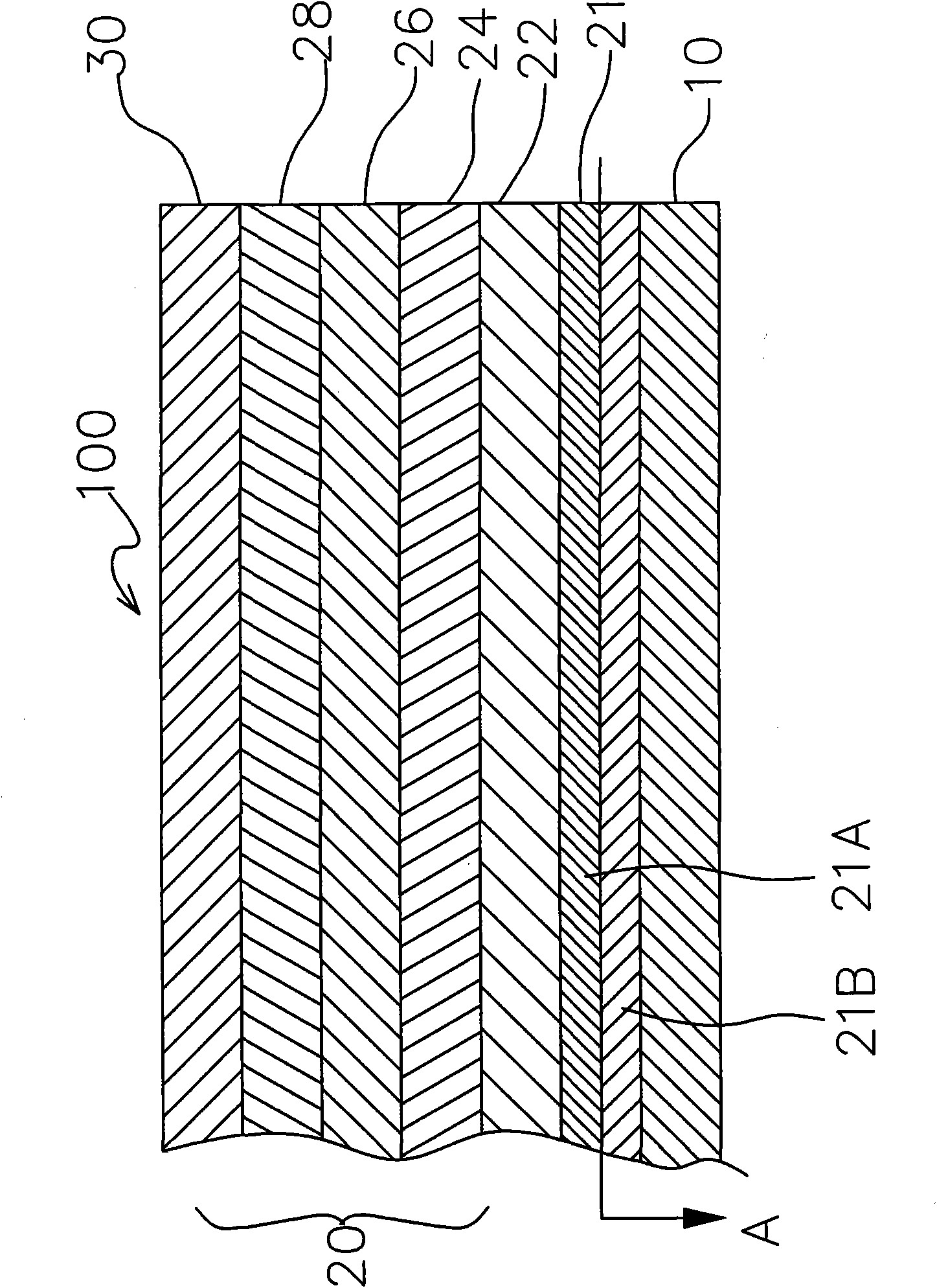

[0030] See figure 1 , figure 2 As shown, the transfer film structure with a three-dimensional matte pattern of the present invention includes a substrate layer 10 and a transfer film 20; wherein, the material of the substrate layer 10 can be a plastic film, such as a PET film (Polyethylene terephthalate) , PP film, PVC film, ARM film, etc., in this embodiment, the PET film is not easy to wrap around and has a high degree of brevity, so it is a basic material for extruded films and plates; the transfer film 20 further includes There is a release display layer 22, a coloring layer 24, a protective layer 26, an electroplated aluminum layer 28, and a primer layer 30.

[0031] The release display layer 22 is relatively attached to the base layer 10. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com