Controllable pitch propeller for ship

A marine propeller and pitch technology, applied in ship construction, ship propulsion, ship parts, etc., can solve the problems of high price, complex and expensive system, difficult application of transport ships, etc., and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

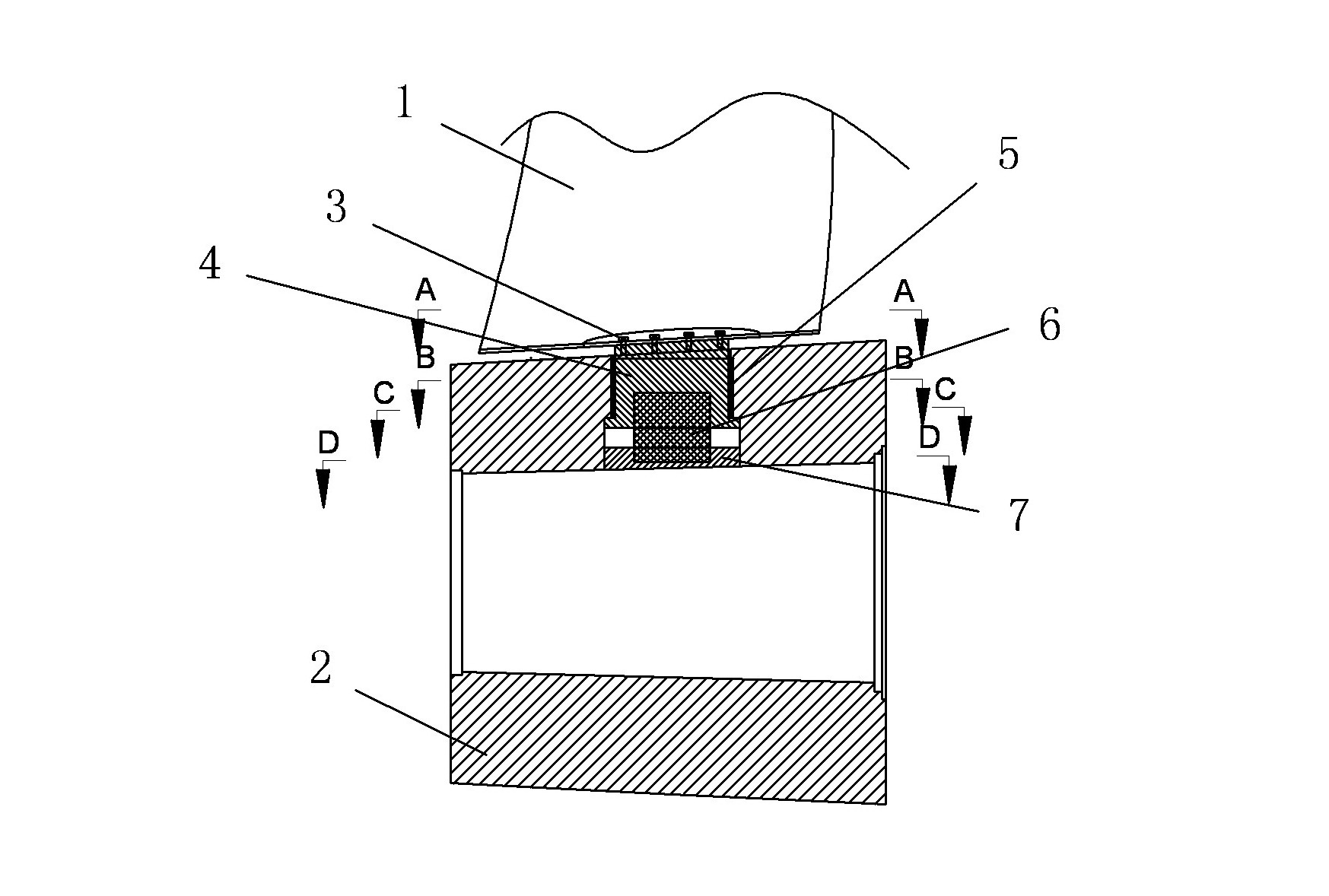

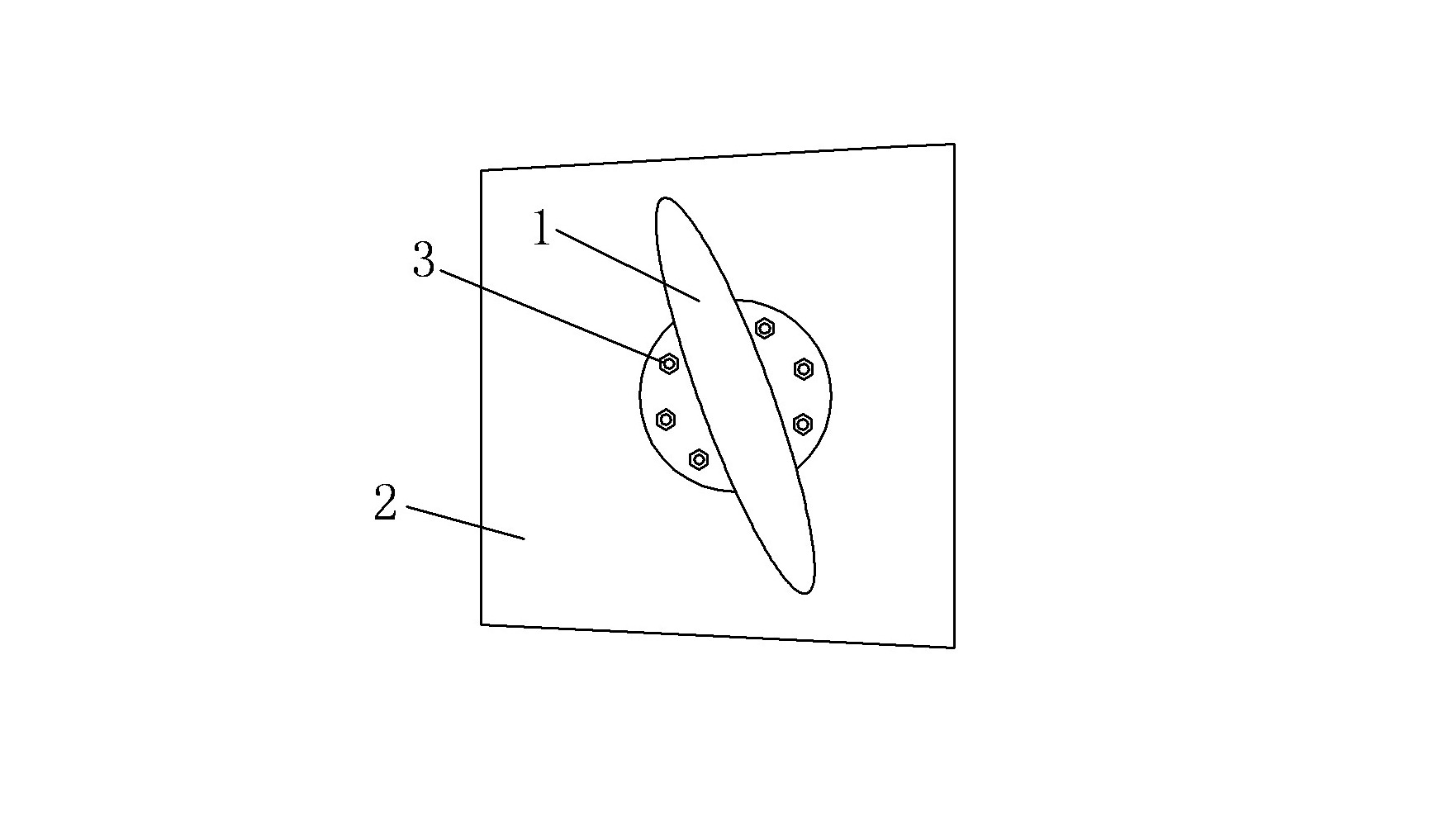

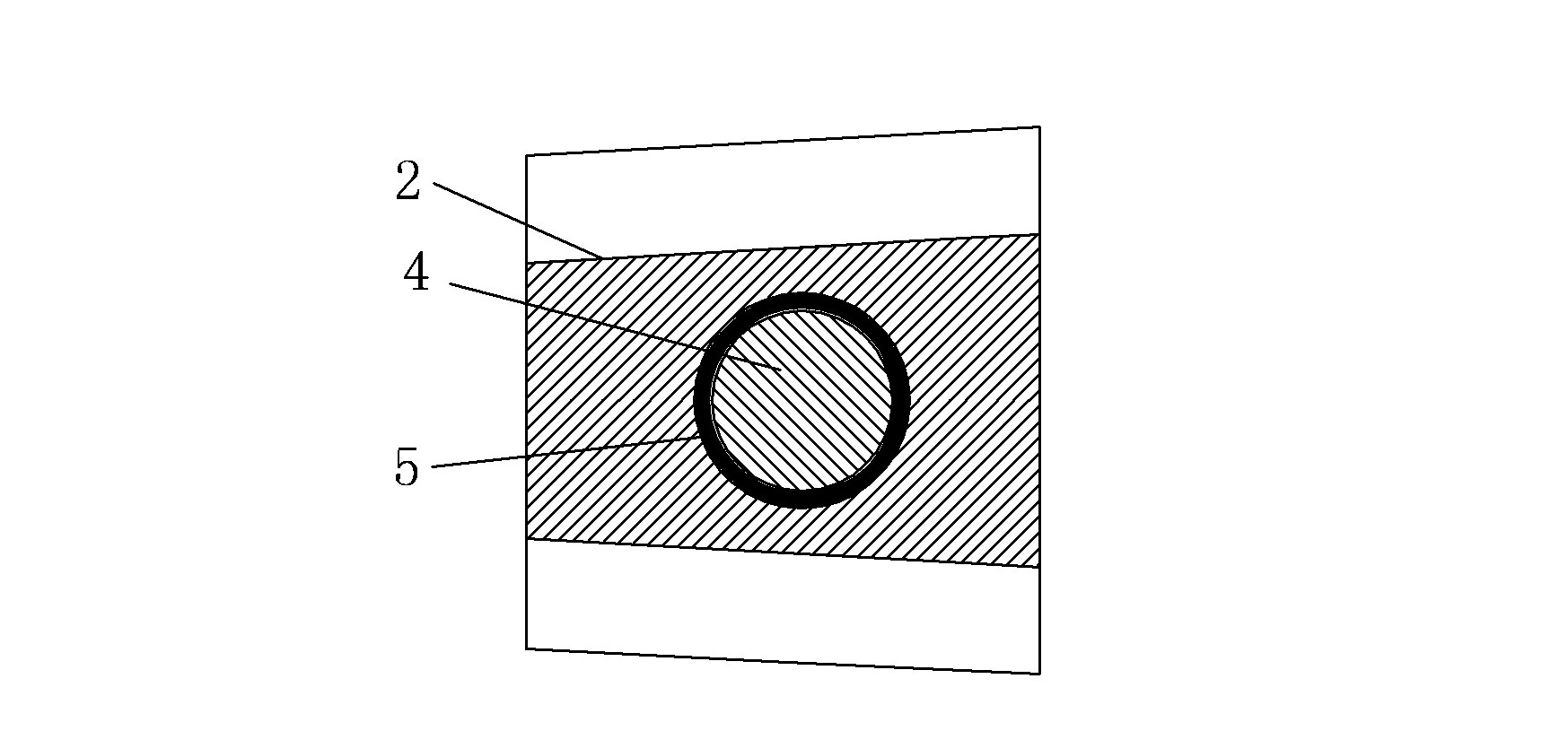

[0015] The elastic blade root variable-pitch marine propeller includes a propeller hub 2 and a plurality of propeller blades 1. Bolts 3 are used to fix the connector 4 at the lower end of each propeller blade 1. The connector 4 is inserted into the mounting hole of the propeller hub 2 to be rotatable. The propeller hub 2 The fastening ring 7 is fixed at the bottom of the mounting hole, and there is a gap between the fastening ring 7 and the connecting piece 4. The two ends of the elastic blade root 6 are respectively inserted into the connecting piece 4 and the fastening ring 7 and fixedly connected. The material of the elastic blade root 6 can use PP-medium melting fat engineering plastic model SP179, or use natural rubber model SCR5, or synthetic rubber BR9000 butadiene rubber. When the torque on the propeller 1 increases or decreases, the elastic blade root 6 can be twisted and deformed or restored to its original shape, so that the propeller 1 can rotate around the blade sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com