Automatic metal round bar feeder

A technology of automatic feeding and round steel, applied in conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of high labor intensity, low safety factor, and inability to realize production automation, and achieve easy maintenance and full automation. , to ensure the effect of automation throughout the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

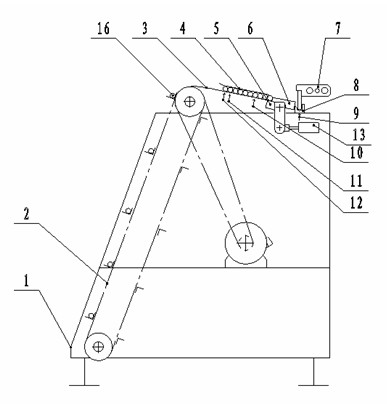

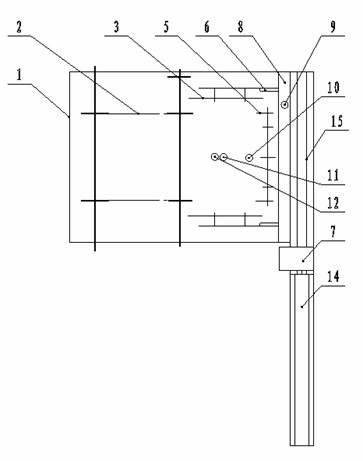

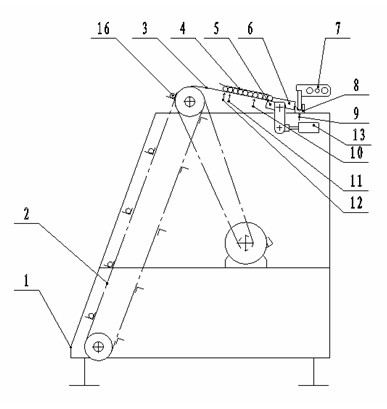

[0015] An automatic feeder for metal round steel, including a lifting system, a material distribution system and a material pushing system connected in sequence, wherein: the lifting system is used to lift metal bars from a low place to a high place, and the high place material distribution system Sequentially, one by one, the metal bars are divided into the pushing system, and then each metal bar is sent to the next process in an orderly manner by the pushing system.

[0016] Such as figure 1 As shown, the lifting system 2 includes: a motor, a reducer, two sprockets, a chain, a lifting block, etc., the motor and the reducer are arranged on the frame 1, and the reducer is connected to a chain arranged above the frame through a transmission belt. The two sprockets set above and below the frame are connected by a chain, and lifting blocks are evenly spaced on the chain; a start switch and a contactor are set in the starting circuit of the motor.

[0017] Such as figure 1 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com