Grafted modified starch slurry

A modified starch and sizing technology, applied in the field of textile sizing, can solve the problems of high cost, high water and electricity consumption, etc., and achieve the effects of improving mechanical properties, saving raw materials and energy, and reducing production costs

Inactive Publication Date: 2011-05-11

四川海旺科技有限公司

View PDF0 Cites 30 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the grafted starch is mainly based on the wet method, w

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

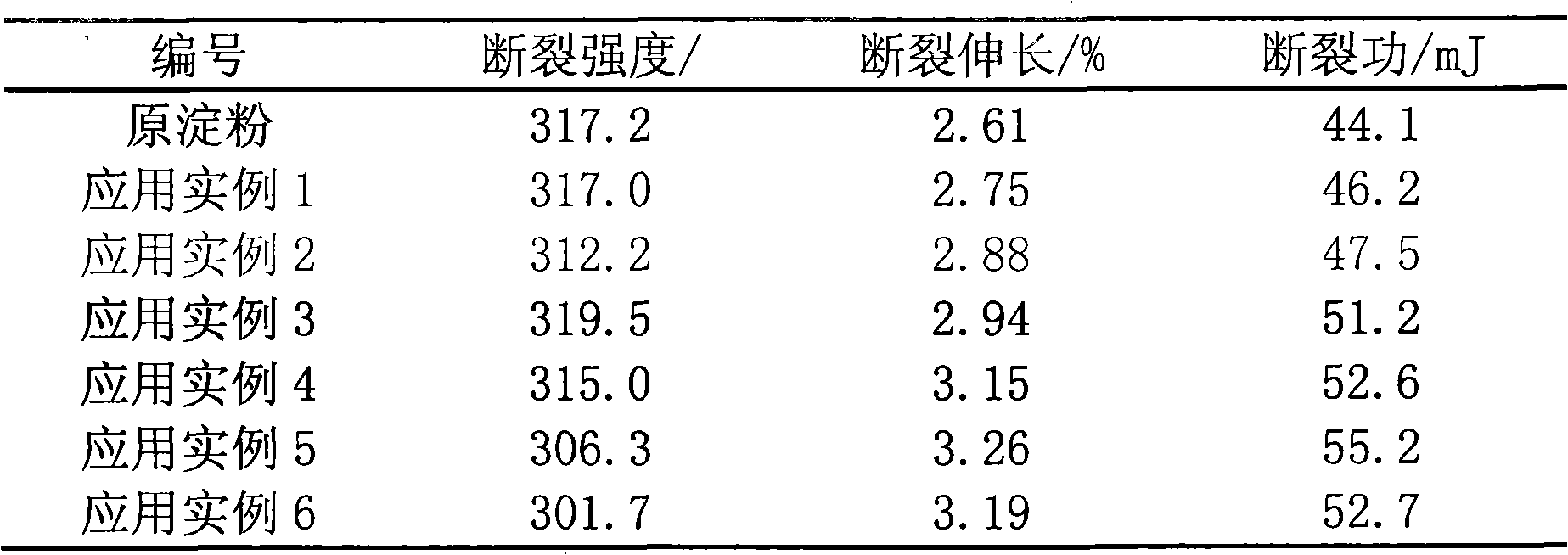

The invention discloses grafted modified starch slurry. The spinning slurry composition consists of the following raw material components in part by weight: 100 parts of native starch, 1 to 50 parts of grafting monomer and 0.1 to 5 parts of initiator, wherein the grafting monomer is any two of acrylic acid, methyl acrylate, methyl methacrylate, ethyl methacrylate, butyl acrylate, butyl methacrylate and acrylamide; and the initiator is any one or more of ammonium ceric nitrate, potassium persulfate, ammonium persulfate, potassium permanganate and H2O2-Fe<2+>. Compared with the prior art, the invention has the advantages that: binary grafted modified starch is prepared from 100 weight parts of native starch, 1 to 50 weight parts of grafting monomer and 0.1 to 5 weight parts of initiator by a dry method, so that the mechanical property of the starch slurry is obviously improved, the raw materials and energy are saved, and production cost is greatly reduced.

Description

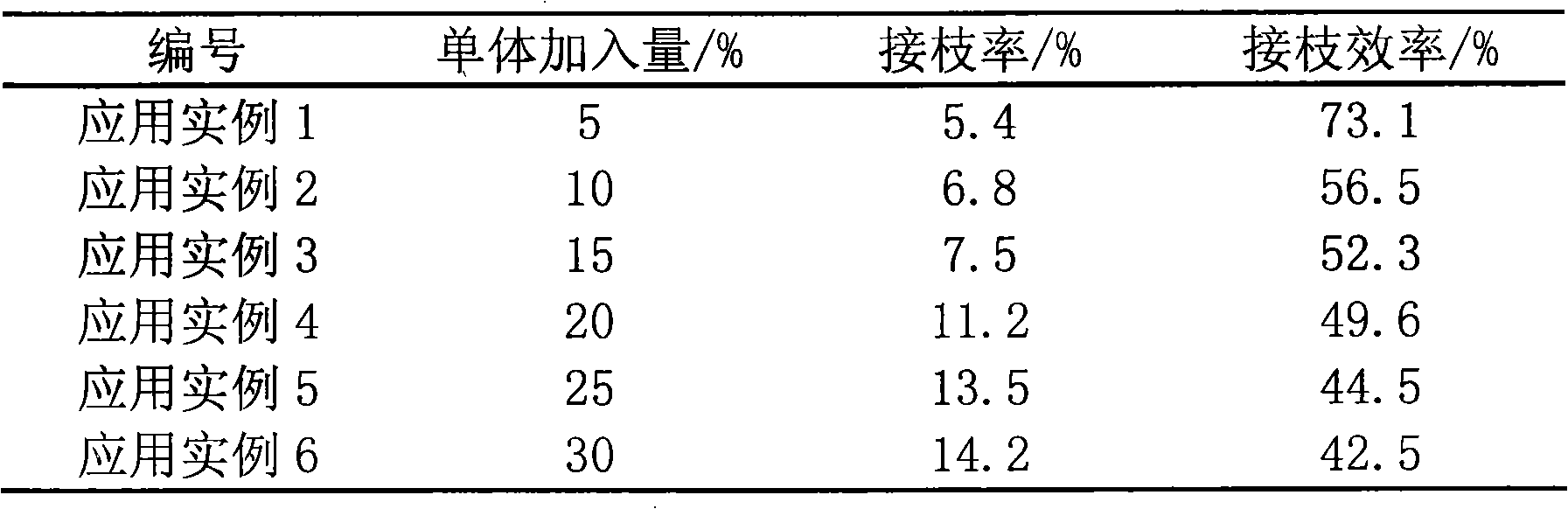

technical field [0001] The invention relates to the field of textile size, in particular to a grafted starch size and a preparation method thereof. Background technique [0002] Starch is currently the most used warp sizing material. It is a renewable resource with a low price and can be completely biodegraded. However, due to the semi-rigidity of the glucose residues on the starch macromolecular chains and the strong hydrogen bonds between the starch molecules, the starch slurry has a high viscosity, the size film is hard and brittle, and lacks adhesion to synthetic fibers. Therefore, improving the performance of starch size is an important topic in the field of sizing materials. [0003] Grafted modified starch is a kind of chemical modification of starch, and it is one of the suitable sizing materials to replace PVA. It usually uses vinyl-based monomers to form a synthetic polymer branch chain with a certain degree of polymerization on the main chain of starch macromole...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08F251/00D06M15/11

Inventor 邱绪良巫拱生

Owner 四川海旺科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com