Chemigum resisting dynamic ozone

A technology of nitrile rubber and ozone, applied in hoses, mechanical equipment, pipes/pipe joints/fittings, etc., can solve problems such as oil leakage and cracking, and achieve the effect of improving static resistance, heat resistance and elasticity.

Active Publication Date: 2011-05-11

TIANJIN PENGYI GRP CO LTD

View PDF1 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Under normal circumstances, nitrile rubber is usually used as the inner layer of the hose because of its good oil resistance, but the two ends of the hose are directly in contact with the air. Once cracks are formed due to ozone, they will develop along the cracks to the inner wall of the hose, eventually leading to oil leakage The phenomenon occurs, and the pure nitrile rubber will crack within 24 hours under this condition.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

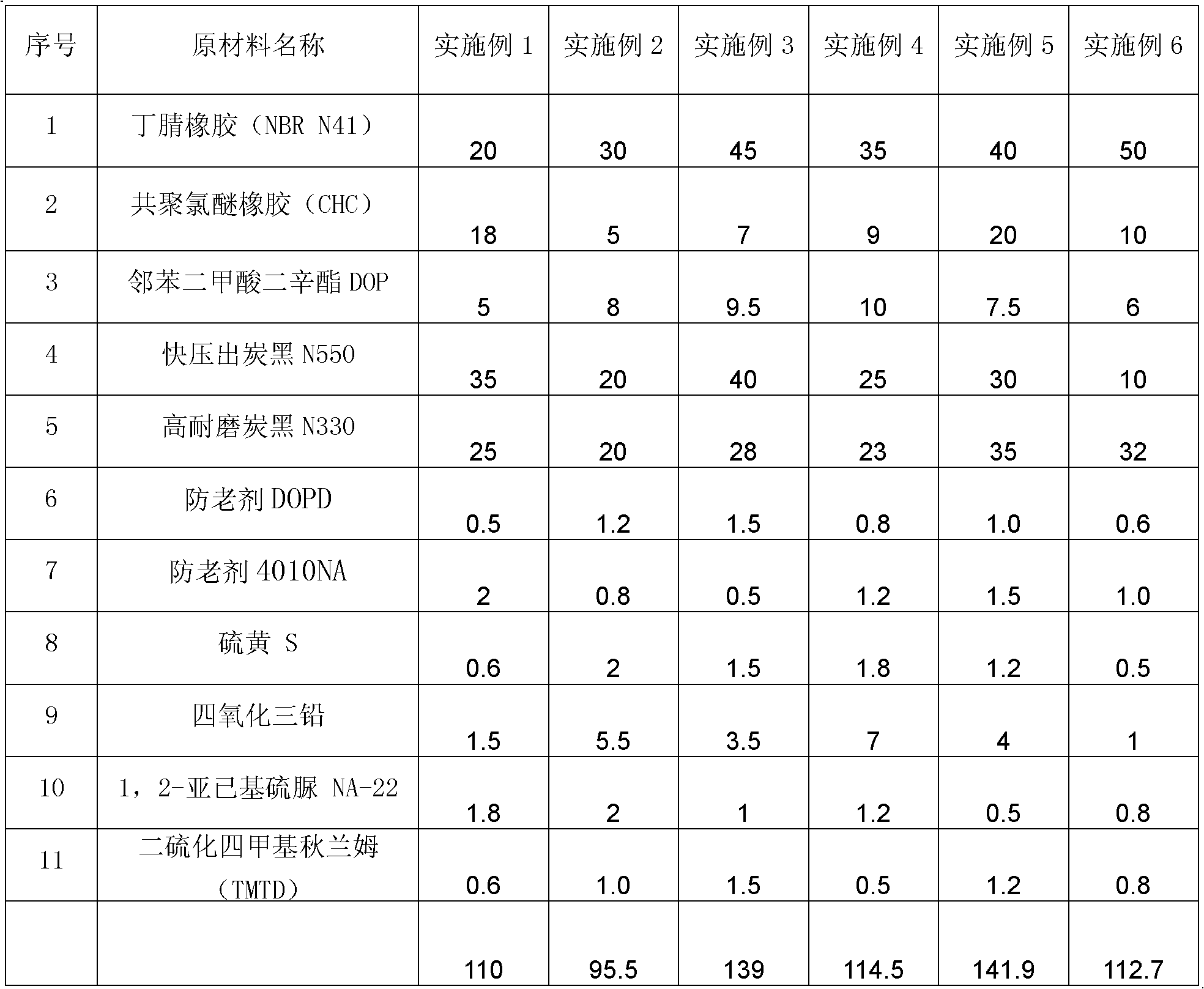

[0029] Examples of dynamic ozone-resistant rubber are shown in the table

[0030] Content in parts by mass:

[0031]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to chemigum resisting dynamic ozone, prepared from the following components in parts: 20-50 parts of chemigum, 5-20 parts of poly(epichlorohydrin co oxirane), 5-10 parts of dioctyl phthalate, 10-40 parts of fast extruding carbon black, 20-35 parts of high-abrasion carbon black, 0.5-1.5 parts of age inhibitor DOPD, 0.5-2 parts of age inhibitor 4010NA, 0.5-2 parts of brimstone, 1-7 parts of lead tetraoxide, 0.5-2 parts of 1,2-hexylidene thiourea and 0.5-1.5 parts of tetramethylthiuram disulfide. By jointly using poly(epichlorohydrin co oxirane) and simultaneously adding the age inhibitor DOPD and the age inhibitor 4010NA, the invention greatly improves the performance of the chemigum for resisting static and dynamic ozone.

Description

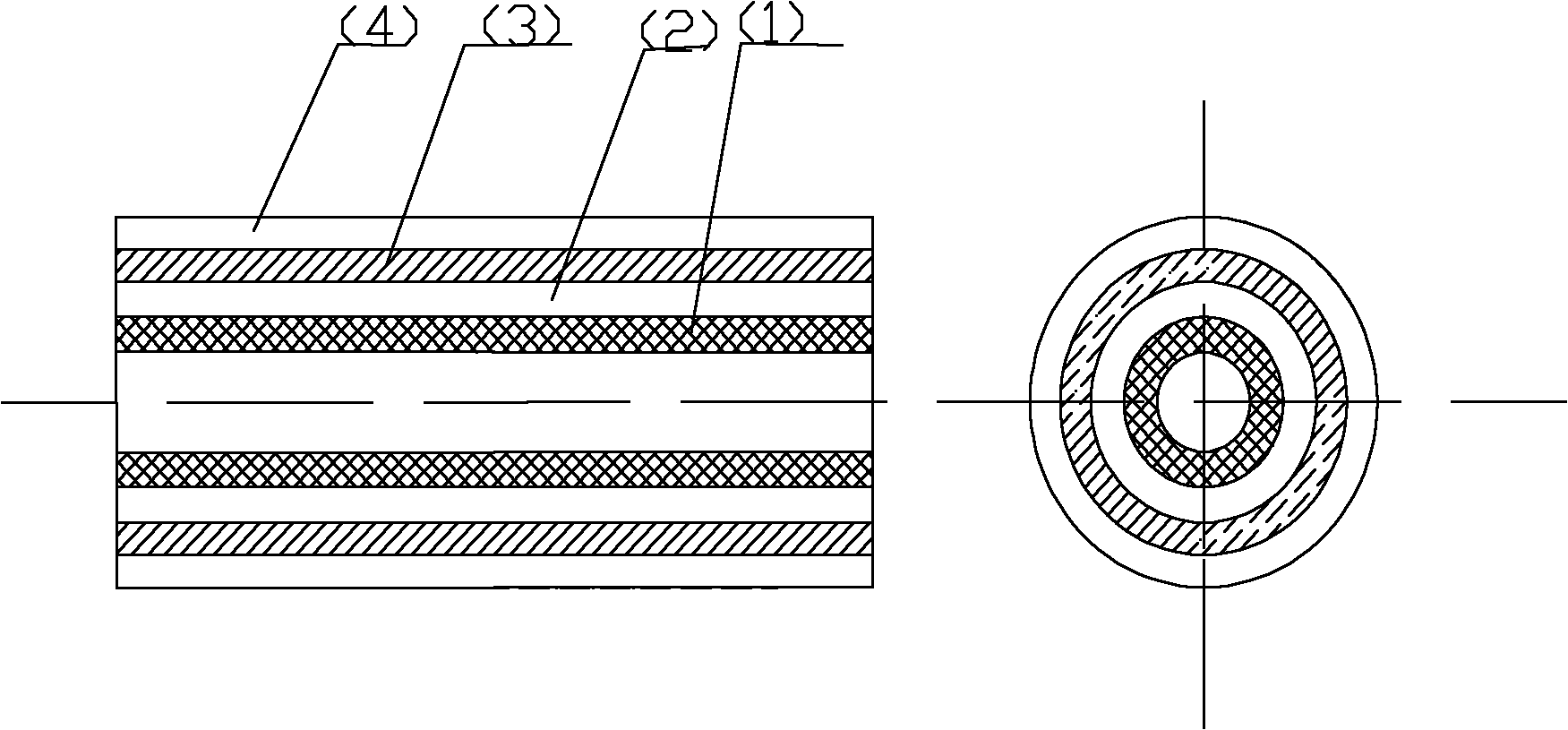

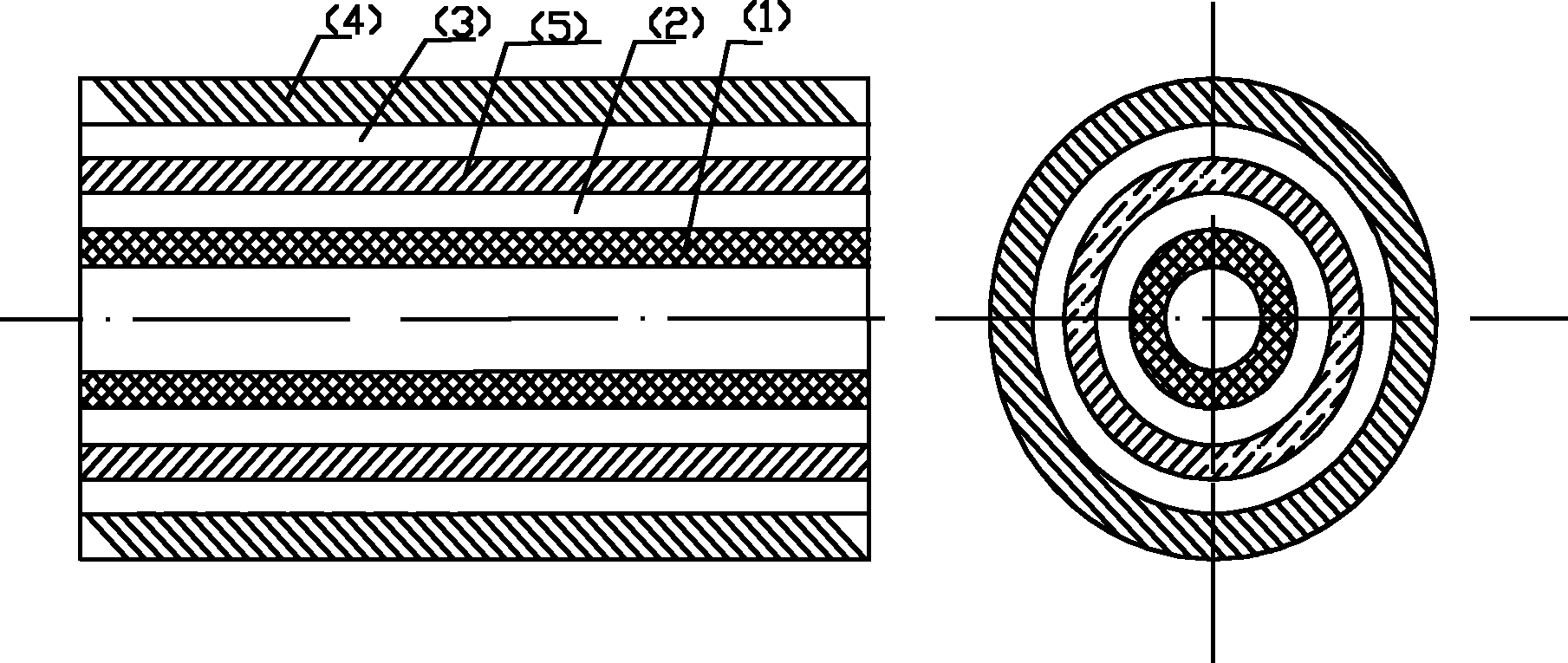

technical field [0001] The invention relates to the technical field of rubber hoses, in particular to dynamic ozone-resistant nitrile rubber. Background technique [0002] As a means of transportation for human beings, automobiles have been integrated into people's daily life, and it is particularly important to maintain the function of rubber pipes connecting automobile fuel systems, cooling systems, and heat dissipation systems. With the development of the automobile industry, the use environment of rubber hoses for automobiles is getting worse and worse. As rubber connecting hoses for automobiles, they will vibrate and stretch with the unevenness of the road conditions. Under normal circumstances, the static ozone resistance of nitrile rubber is acceptable. , but under the condition of bad road conditions, the automobile connecting pipe is in dynamic state, which requires the nitrile rubber to be resistant to dynamic ozone in addition to static ozone resistance, in an ozo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L9/02C08L27/06C08K13/02C08K5/12C08K3/04C08K3/22C08K5/18C08K5/405C08K5/40F16L11/04

Inventor 张洪起张学震

Owner TIANJIN PENGYI GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com