A kind of technological method of processing automobile stator or rotor with silicon steel sheet

A process method and technology of silicon steel sheets, which are applied in the manufacture of stator/rotor bodies, electromechanical devices, electrical components, etc., can solve the problems of increasing the axial length of the motor, occurrence of grounding accidents, scratching the stator bar, etc. To length, to prevent vibration and wear, to avoid the effect of uneven force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

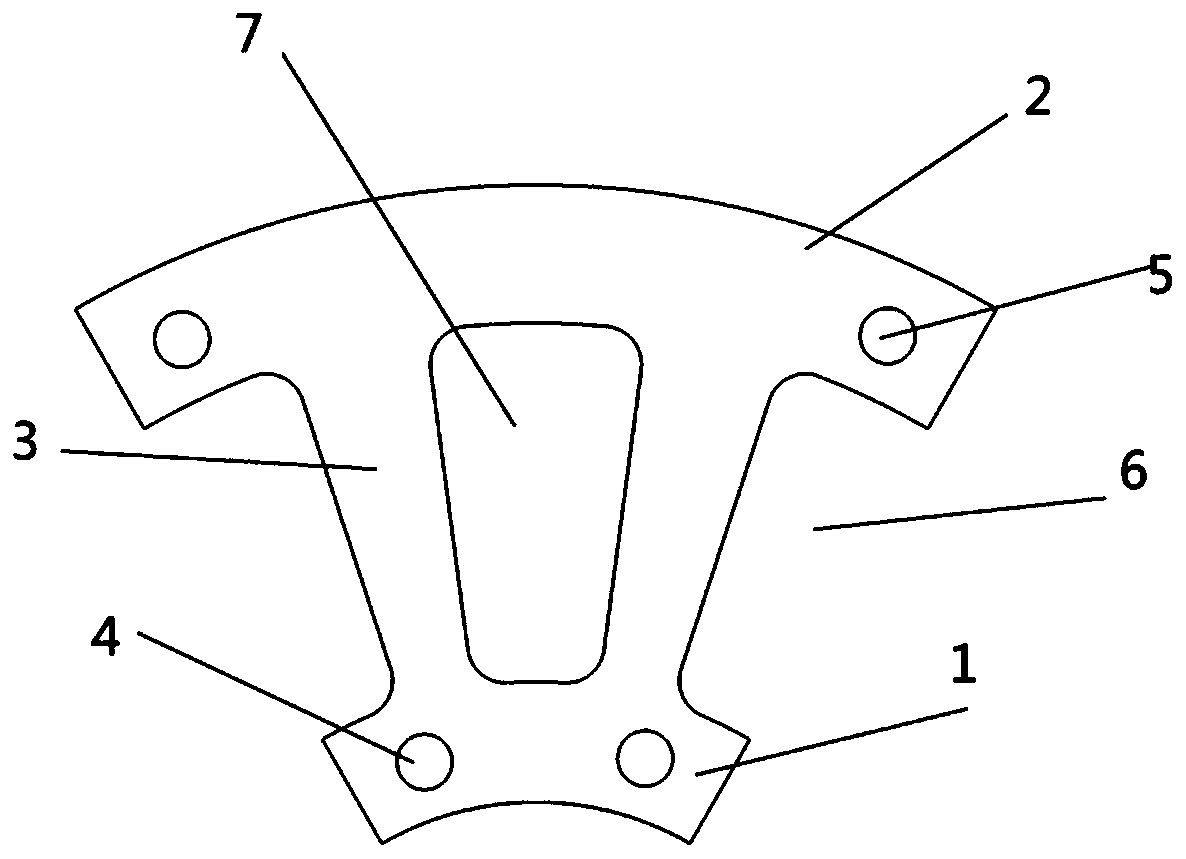

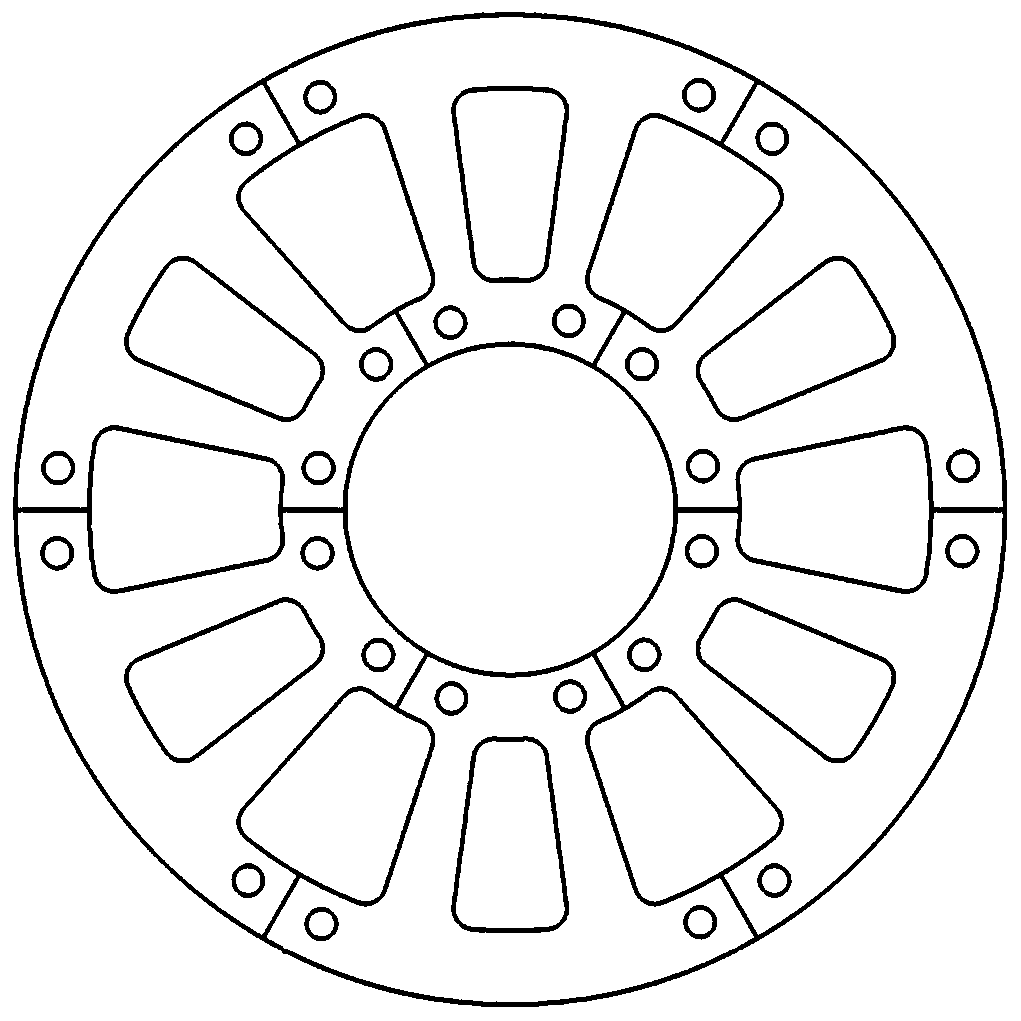

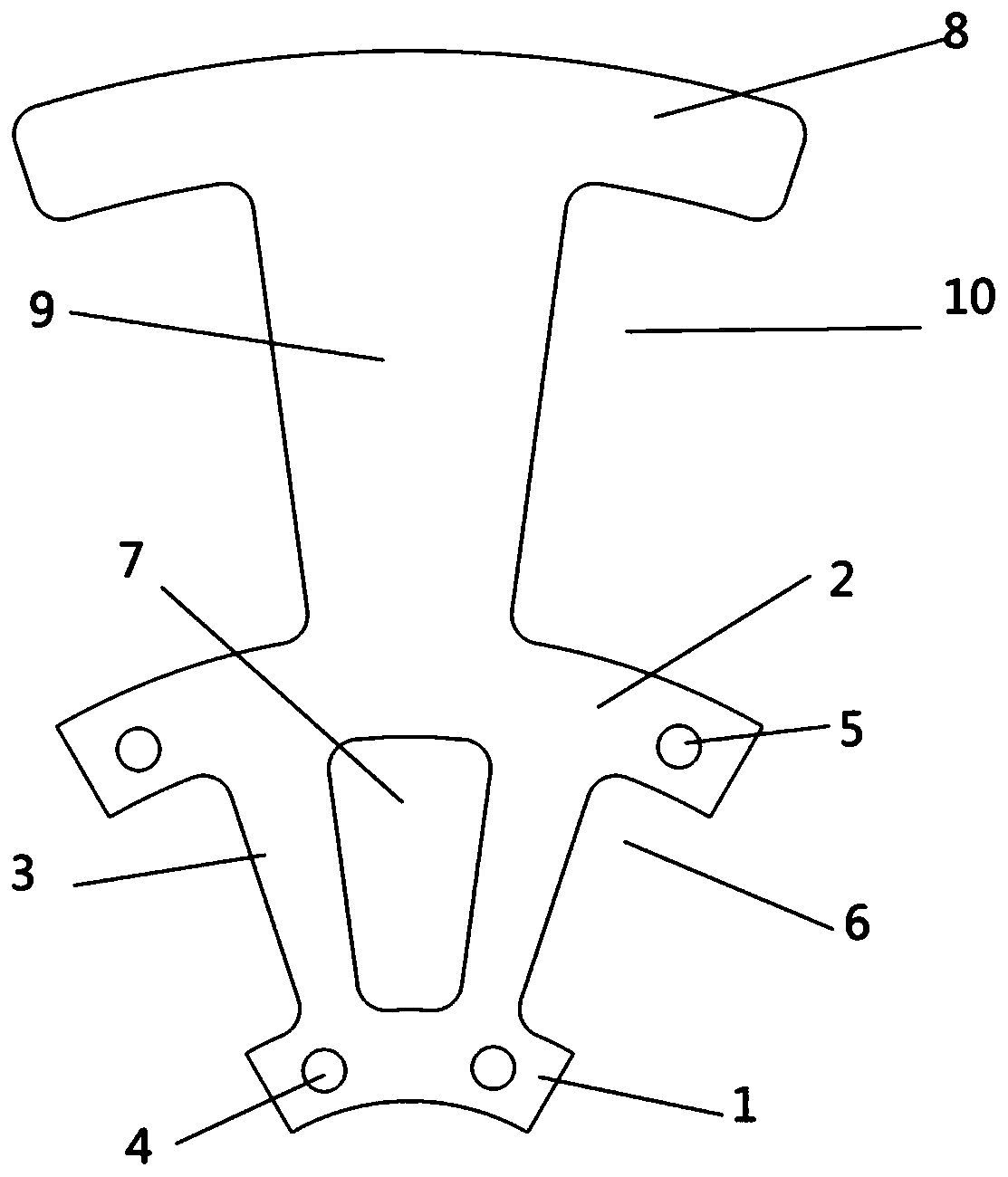

[0043] figure 1 A schematic diagram of an embodiment of the silicon steel sheet unit of the present invention is shown, including a plurality of silicon steel sheet units inserted into each other, and the silicon steel sheet unit includes an inner arc plate 1 and an outer arc plate 2; an inner arc plate 1 and an outer arc The plates 2 are concentric, and the arc length of the outer arc plate 2 is greater than the arc length of the inner arc plate 1; this makes the silicon steel sheet formed by the silicon steel sheet unit a full circular structure; further, in order to improve the overall strength, the inner arc plate 1 There are two ribs 3 between the outer arc plate 2, so that the middle of the two ribs 3 and the inner arc plate 1, a cavity 7 is formed between the outer arc plate 2, the left side of the left rib plate and the inner arc plate 2 An open left half cavity-6 is formed between the arc plate 1 and the outer arc plate 2, and an open right half cavity-6 is formed bet...

Embodiment 2

[0055] It also includes a method for manufacturing the silicon steel sheet in Embodiment 1, characterized in that it includes the following steps:

[0056] 1) Process silicon steel sheet unit blanks: cast silicon steel sheet unit blanks through molds, and keep the cast blanks at a temperature of 450°C to 500°C for 2 to 2.5 hours;

[0057] 2) Polishing treatment: The silicon steel sheet unit blank is polished twice by water jet; the first polishing jet liquid is 6.3-8.5 parts of water, 3-5 parts of abrasive particles, 0.03-0.2 parts of sodium polyacrylate, and 2.5 parts of sodium persulfate. ~3 parts and 1~2 parts of leucine; injection pressure: 1.3~1.5Mpa, distance between spray gun head and blank: 15~25cm, angle between jet stream and blank: 45~60 degrees, spray Sanding time: 15-20 minutes. The second polishing spray liquid is composed of 8.3-10.5 parts of water, 1-3 parts of abrasive particles and 1-2 parts of leucine; injection pressure: 0.5-0.8Mpa, distance between spray ...

Embodiment 3

[0067] It also includes a process for processing an automobile stator or rotor with the above-mentioned silicon steel sheet,

[0068] 1) Determine the height of the stator or rotor to be processed;

[0069] 2) Apply the adhesive on both sides of the silicon steel sheet, and apply the glue evenly to avoid leakage points. 0.2%, the thickness is less than 0.1 mm; the silicon steel sheet coated with adhesive is passed through the fixed shaft and placed in a mold matching the shape of the silicon steel sheet to fix it, and the vertical tolerance between the two silicon steel sheets is less than 0.05 mm; one end of the mold is for The open structure of the press rod of the hydraulic press;

[0070]3) Install the mold on the hydraulic press, and heat the silicon steel sheet and the adhesive to 50°C with an electric heating unit, and apply a pressure of 2500N. After keeping the pressure for 2 hours, apply a pressure of 8000-10000N and keep it for 10 hours. The adhesive is fully cure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com